Semiconductor Inspection

Precision. Speed. Reliability. At every step of the line.

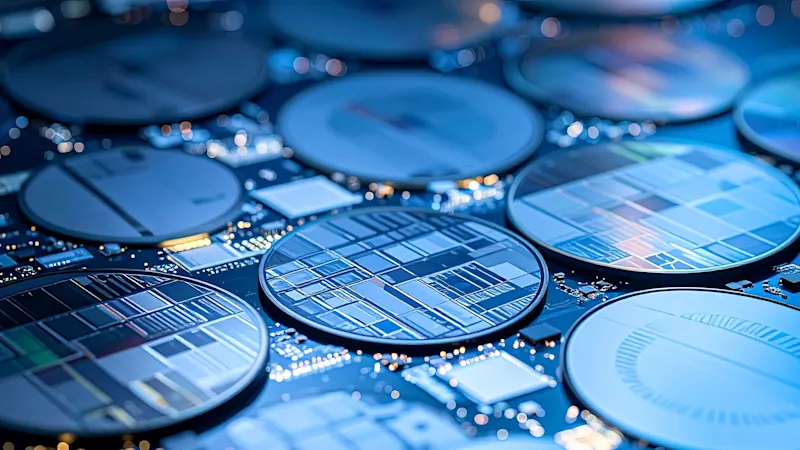

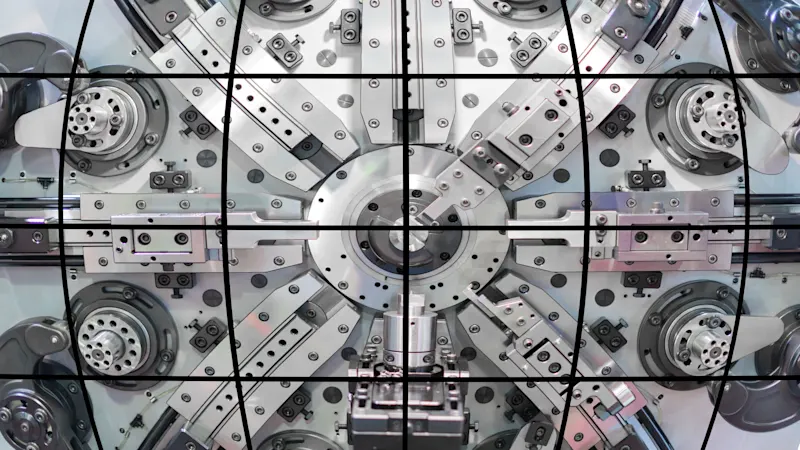

Semiconductor manufacturing is complex—ultra-fine structures, fast cycle times, and stringent quality standards. Each step demands precise vision inspection. For decades, Basler has partnered with industry leaders to develop vision solutions for semiconductor quality assurance. From wafer processing to final packaging, Basler delivers the speed, precision, and reliability required for high-performance semiconductor production.

High performance & speed

Innovative, high-performance camera technology for state-of-the-art production methodsIndustry-leading reliability

Basler cameras have one of the lowest failure rates in the industry — built for continuous, 24/7 operation.Simple integration

All of our components are compatible and easy to connect to target systems using pylon softwareAvailability & reliable delivery

Stable supply chains ensure long-term availability of our products and prevent production downtime

Real-World Solutions for Semiconductor Inspection Challenges: Customer Case Studies

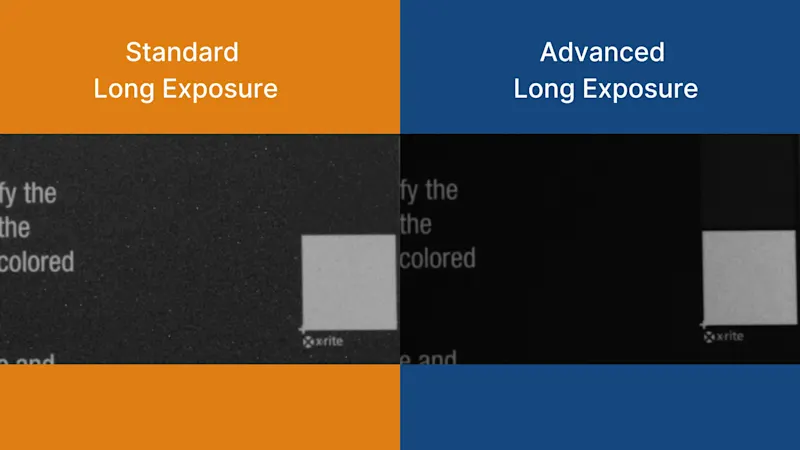

Semiconductor defect inspection demands speed, precision, and clarity. Basler delivers with real-time processing, superior image quality, advanced optics, and AI-compatible software—all seamlessly integrated for fast, reliable inspections.

Advanced Vision Technology for High-Performance Semiconductor Inspection

From vision system design to specialized camera features to addressing industry-specific challenges - Basler enables inspection precision at every level.

Most popular products

For efficient and reliable machine vision applications in this industry, the following Basler products are often the best choice:

FAQs

Basler goes beyond standard camera solutions by providing tailored imaging setups to meet your unique requirements. Customization can include:

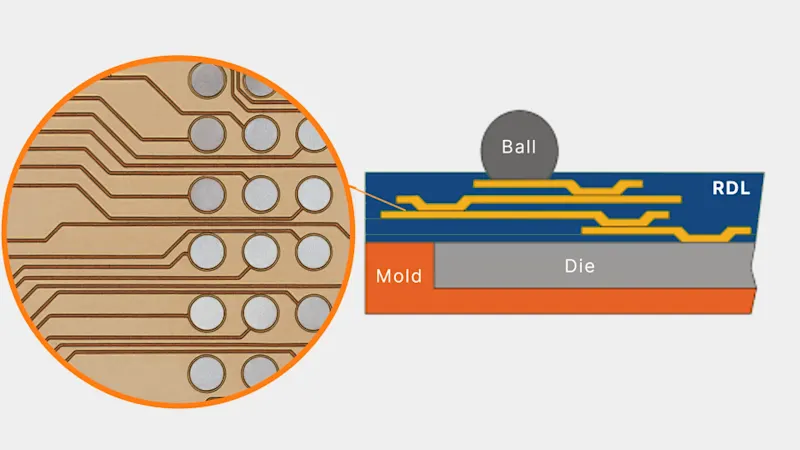

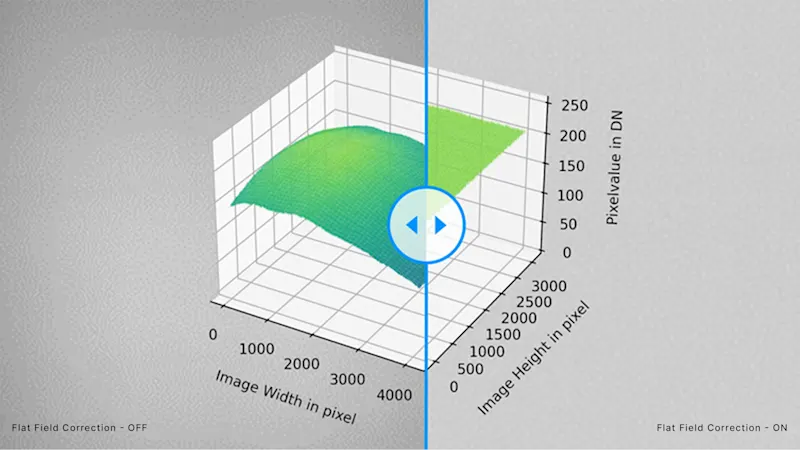

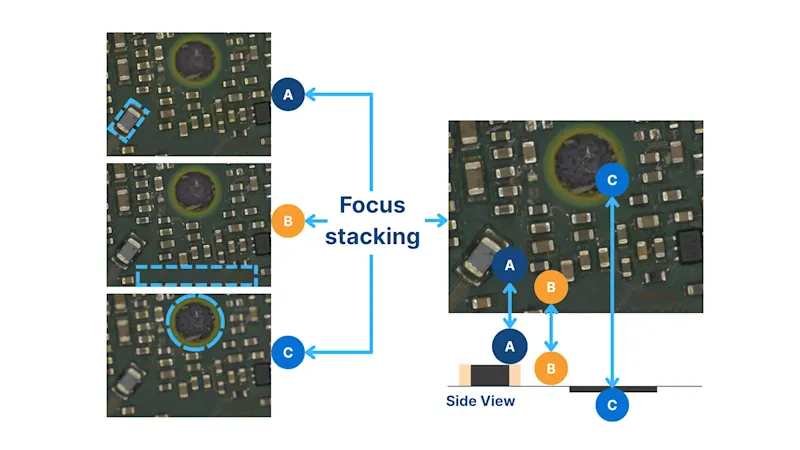

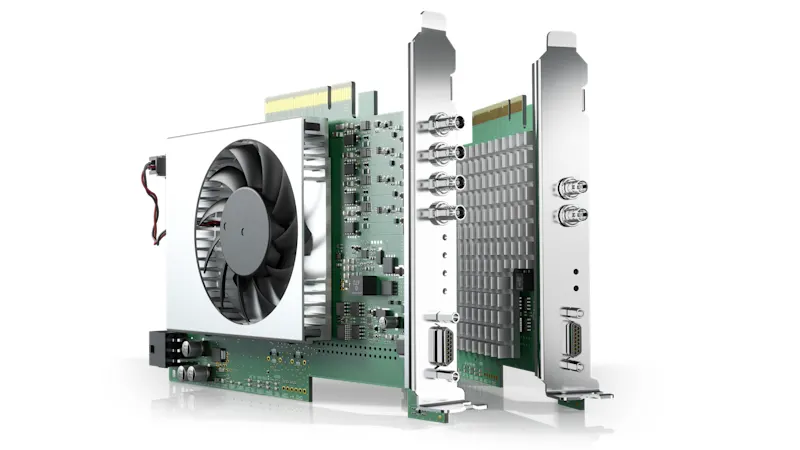

FPGA-Based Preprocessing: Basler cameras can integrate advanced image processing directly on the FPGA (or Field Programmable Gate Array), enabling features like flat-field correction, distortion correction, defect detection, and even photometric stereo, all within the camera. This reduces latency and minimizes reliance on external CPU/GPU resources, which is critical for high-speed semiconductor lines.

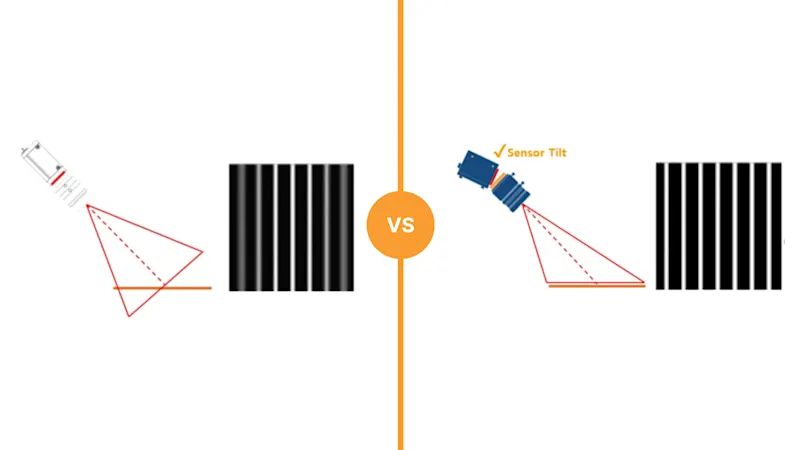

Optics and Illumination Design: Basler works with customers to select or design lenses and lighting systems optimized for specific wafer sizes, substrates, and inspection tasks. Telecentric lenses and specialized lighting solutions ensure non-distorted, high-contrast images.

Interface and Bandwidth Options: Customers can choose from industrial interfaces such as GigE Vision or CXP to meet bandwidth and speed requirements. Basler also provides plug-and-play frame grabbers for complex preprocessing needs.

Selector Tools and Engineering Support: Basler offers tools like the Lens Selector and Camera Selector, which allow customers to input their unique parameters to find a tailored solution. Additionally, Basler’s Field Application Engineers provide hands-on guidance during design and integration phases.

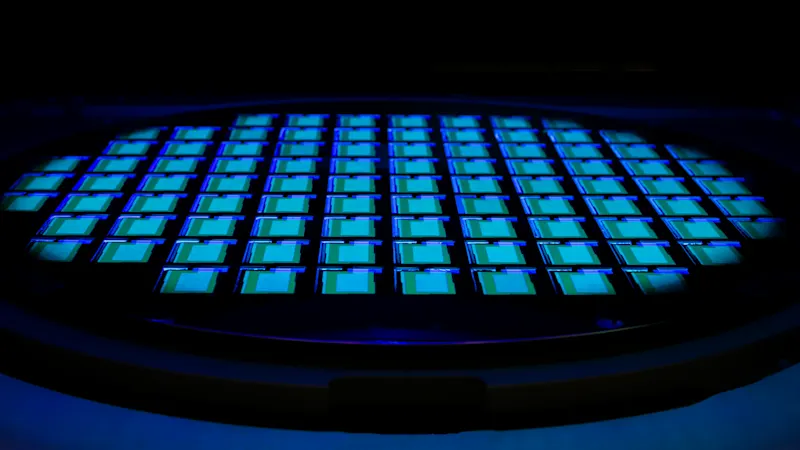

Single Shot:

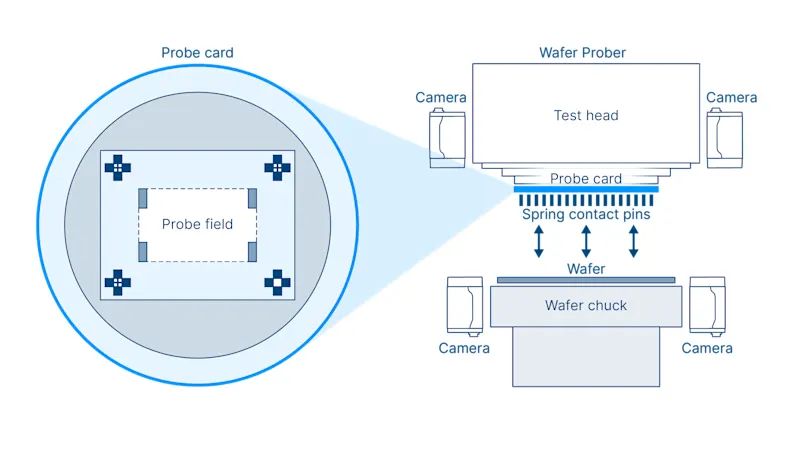

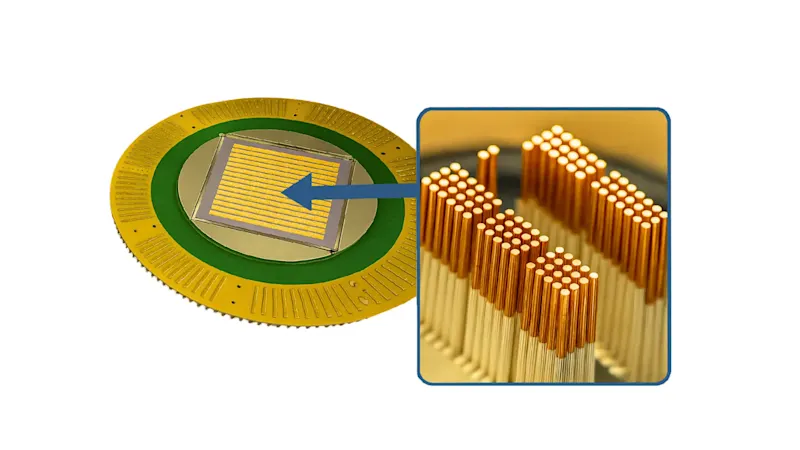

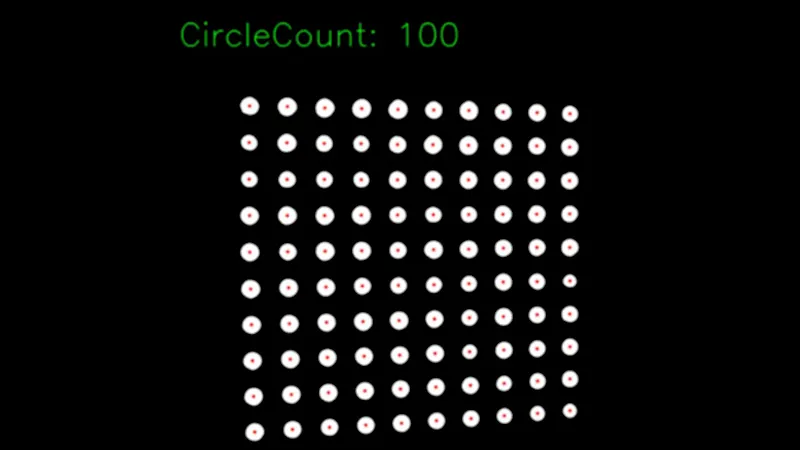

Ideal for static wafers where the entire surface can be captured in one exposure. This method delivers high accuracy and minimizes stitching errors.

Multi-Camera Stitching:

When a single camera cannot cover the entire wafer due to size or space limitations, multiple cameras are positioned to capture overlapping sections. Advanced stitching algorithms combine these images into a seamless view, ensuring full coverage without sacrificing resolution.

Line Scan:

Perfect for continuous movement scenarios, such as conveyor belt systems. A line scan camera captures one line at a time as the wafer moves beneath it, creating a complete image. This approach is highly efficient for high-speed processes but demands consistent motion and minimal vibration.

Each approach is chosen based on process requirements and physical constraint.

Vision systems are often a secondary thought in semiconductor lines. This means integration must account for existing process constraints, such as interface compatibility, space restrictions, and object motion. Since the line is often not built with vision in mind, Basler’s flexible solutions are important for seamless integration for various configurations, from single-shot imaging, multicamera stitching, to line scan approaches.

Selecting the right camera, lens, and interface for semiconductor inspection depends on several key factors. Industrial interfaces such as GigE and CoaXPress (CXP) are preferred over USB because they offer higher bandwidth and greater reliability for demanding production environments.

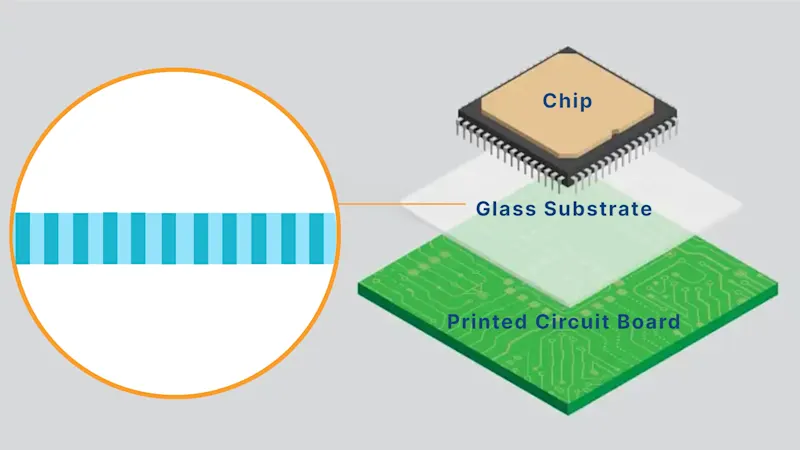

In advanced packaging, some alignment tasks require single-digit-micron precision, but the necessary imaging resolution depends on the stage of the process: front-end applications like full-wafer imaging typically need only about 100-micron accuracy, whereas back-end operations such as die sorting may require much finer detail, approaching 30 microns.

Frame rate is usually less critical but can depend on motion requirements. Our Frame Rate Calculator and expert engineering support make it easy to configure the best setup for your application.

The most common challenges in designing vision solutions for wafer inspection are space constraints and performance in motion.

Space Constraints: Imaging a full wafer in one shot requires a long working distance, which isn’t always feasible. We offer multicamera solutions and area scan options to overcome these limitations.

Motion Variability: Any objects with single direction movement can allow for line scan imaging, but semiconductor processes often use robotic arms, with the risk of introducing vibration and inconsistent movement. Our systems adapt to these conditions with robust hardware and software.

Our complete portfolio allows for easy adaptation to changing wafer sizes and substrates. Customers can select larger sensors or different optics to accommodate new requirements. Upgrades are common during development phases, as the industry evolves rapidly and vision technology becomes more affordable and precise.

Vision solutions are used for defect detection and alignment in increasingly complex 3D structures. Our FPGA-based preprocessing enables real-time correction and defect detection within the camera, reducing latency and improving inspection accuracy.

Learn more about overcoming challenges in semiconductor packaging inspection.

By enabling precise, real-time inspection and defect detection, our solutions help manufacturers catch issues early, reduce waste, improve overall yield and reduce system down time. The integration of FPGA processing within the camera and customizable configurations streamlines workflows.

Lead Times: Most our products ship within 2–4 weeks for small quantities; larger orders can be scheduled to meet customer needs.

Manufacturing: Cameras are made in Germany (Americas/EMEA) and Singapore (APAC).

Quality Standards: We comply with ISO 9001 and other international standards. For compliance details, see our full compliance list.

We offer global engineering support, technical documentation, and internal collaboration between regions. Our Field Application Engineering (FAE) team provides tailored recommendations and troubleshooting, ensuring customers receive the best solutions for their needs. Technical support and product documentation are available online, with regional teams ready to assist.