Overcoming Pixel Defects in InGaAs SWIR Imaging

Our unique algorithm, Pixel Correction Beyond, is engineered to overcome the pixel defects common in industrial SWIR imaging. It goes beyond conventional dynamic defect pixel correction to deliver exceptional image quality. By incorporating the image content and providing flexible adjustment of the correction strength, you achieve significantly better SWIR image results. This means you benefit from increased performance and cost savings while operating your vision system.

The main hindrance to precise measurement results: defective pixels

Defective pixels occur in the image sensors of digital industrial cameras due to manufacturing defects, aging image sensors, or environmental influences. As a result, they can impair the perceived image quality and thus the accuracy of measurements and image results.

Defective pixels in camera sensors

In particular, defective pixels occur in connection with long exposure times, high gain settings, or a sensor operating at high temperatures (creating hot pixels). Although their number is small, they appear as completely black or white pixels and therefore offer no usable information.

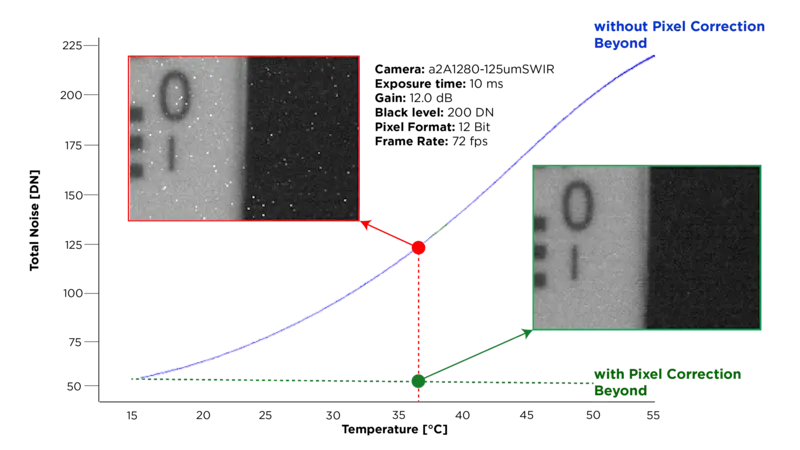

InGaAs sensors are known for their sensitivity to short-wave infrared light. However, they are also inherently prone to pixel defects, with noise levels escalating as sensor temperatures rise.

One Solution: Dynamic defect pixel correction

High measurement accuracy can only be guaranteed by correcting defective pixels. Static correction detects defective pixels during sensor calibration and saves them. Dynamic correction, on the other hand, works continuously on each image while the application is running and can therefore react to changing conditions to correct newly occurring defective pixels. It recognizes and corrects defective pixels even before they leave the camera as image data by adjusting their values to match surrounding pixels in terms of direction and intensity. Such pixel operations are very computationally intensive and time-critical, which is why our Pixel Correction Beyond algorithm is implemented on the camera FPGA.

A further step: Pixel Correction Beyond for SWIR imaging

For industrial users, the question of whether or not to use a cooled SWIR camera hinges on the required image quality. Basler's solution outperforms previous correction algorithms, delivering image quality that matches TEC-based cameras and thus reduce the system cost significantly.

Advantages of Pixel Correction Beyond in SWIR imaging solution

By incorporating the image content, our approach goes beyond conventional dynamic defect pixel correction, offering:

Flexible adjustment of the correction strength

Better correction of structures at the edges of images while retaining image details

Blinking pixels with variable saturation can also be corrected

Our algorithm ensures a uniform and consistent image—and therefore a significant improvement in SWIR imaging quality. Sensitive corrections to image details can be made by adjusting the correction strength. Implementation on a SWIR camera FPGA ensures images are generated at an optimized processing speed without increasing the CPU load.

ace 2 X visSWIR camera models

Find the right camera for your application or use our Vision System Configurator to configure your system.