Bin Picking Solution for Metallic and Shiny Objects

Challenges in bin picking solution for metallic and shiny objects

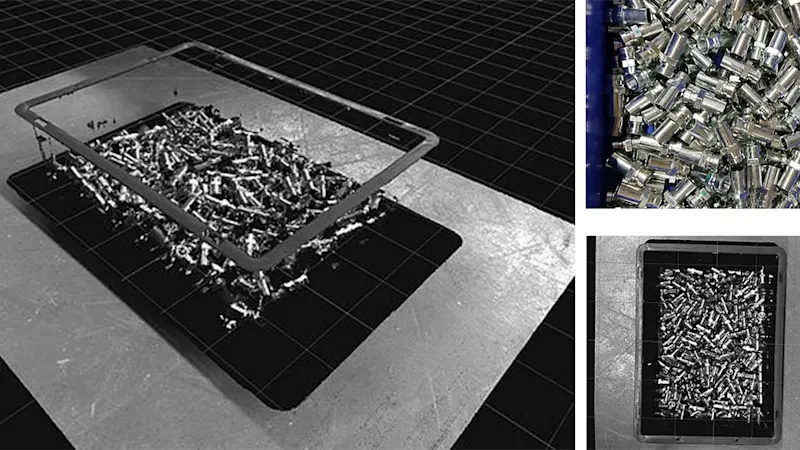

Metallic and shiny objects pose a major challenge to machine vision systems designed to solve picking tasks using vision-guided robotics. The reflections caused by shiny objects cause errors in object localization leading to artefacts in the 3D vision image processing. Nevertheless, the use of robots in automated factories requires accurate bin picking to ensure that objects are correctly identified and selected.

The solution for the inspection of shiny objects: Stereo image processing system with ace cameras

Euclid Labs, a software house from Italy that delivers complete 3D vision-based software solutions, has developed and manufactured their own 3D industrial stereo vision system called Nak3D.

Nak3D consists of two Basler acA1920-155um cameras and a red laser line. The Basler acA1920-155um USB 3.0 camera with the Sony IMX174 CMOS sensor delivers 164 frames per second at 2.3 MP resolution and is highly responsive to red laser light.

Euclid Labs has integrated the cameras and laser line into a reliable stereo vision system: The two cameras and the motor that controls the rotation of the laser are connected to a PC that scans and collects the images from the two cameras and the position of the laser line step-by-step. The acquired 3D data is processed and visualized by the Euclid Labs software suite on an external vision PC.

What the system does in detail:

Moving the laser line

Capturing images with both cameras

Doing full stereo analysis and processing a first point cloud

Filtering the point cloud accepting only points on the laser plane (laser line as a filter)

Adding reliable points to final point cloud

Going to step 1 until laser position reaches the end of scanning volume

The combination of stereoscopy with a laser line allows the system to build a precise 3D image of shiny objects, as the artefacts in the point clouds can be filtered out. For this reason, the Nak3D system is particularly effective with reflective objects compared to other technologies.

When Nak3D system is connected to Euclid Labs’ software suite for bin picking, the software starts from a cloud of points, the software recognizes the pieces and elaborates the trajectories to pick them. Nak3D exists in various sizes for different scanning volumes and could also be customized in a special version with thin laser lines to recognize objects of a few millimeters.

The powerful Nak3D vision system by Euclid Labs enables accurate random bin picking of metallic and shiny parts and loading them into machines or conveyors for further processing. The solution is very cost-efficient compared to structured light products, offering robot manufacturers, machine builders and system integrators the chance to create bin picking solutions for challenging tasks, in line with market requirements.

Develop your 3D vision solution with our broad computer vision portfolio

Basler offers a wide choice of high-quality 2D and 3D imaging components and accessories to let you create your application-specific 3D vision solution. In addition to machine vision hardware we also offer support in implementing the corresponding software solutions.

Products for this solution

Looking to implement a comparable solution? These products will help you.