Basler ace cameras and frame grabbers improve AOI system

Fault detection in the manufacture of electronic circuit boards

To prevent process errors in the production of circuit boards, the Delvitech company offers AOI systems.

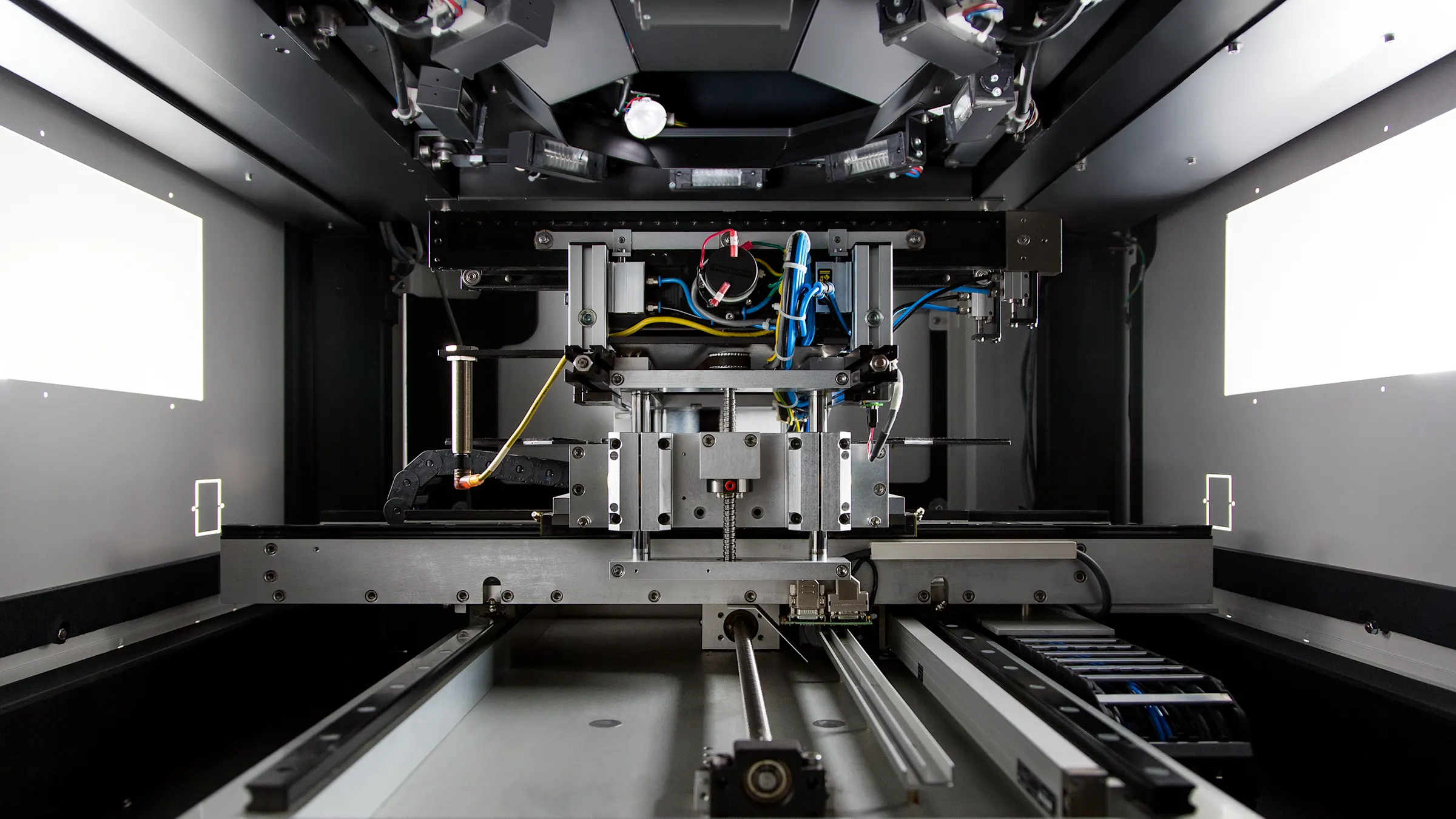

The most important system component is an optical head consisting of five cameras and lighting arranged on the sides. Delvitech developed an upgrade of the optical head for its AOI systems installed on the market. More powerful cameras and frame grabbers along with a graphic FPGA development environment enable higher speeds, accuracy and flexibility, thus leading to higher customer demand.

Requirements for the inspection of electronic circuit boards

The cameras that were installed before the AOI system upgrade did not deliver the desired image quality and speed. For this reason, Delvitech was searching for new industrial cameras for the optical camera head, which would offer a higher resolution, a frame rate of at least 30 frames per second and a suitable camera interface with a high bandwidth. Delvitech was also looking for matching frame grabbers, since the ones they had used so far were only suitable for special cameras. All new hardware and software components (camera, frame grabber, software, lighting) in the image processing system had to be compatible with each other.

The most important requirement for the overall system was its scalability via changing cameras and frame grabbers.

AOI system solves challenge in electronic circuit board inspection

The optical head of the AOI system consists of a camera on top, four cameras on the side, 24 xenon light sources, four RGB LEDs and one sensor. Since the upgrade, Delvitech has used a CMOS area scan camera with CoaXPress interface for the upper camera. For the side cameras, the company now installs four monochrome Basler ace Classic CMOS area scan cameras with Camera Link interface. Each delivers 180 frames per second at 4 MP resolution.

To ensure that the frame grabbers are compatible with the other components, two different programmable frame grabbers from Basler are used. The microEnable 5 marathon VCX-QP CoaXPress frame grabber synchronizes the upper camera and the lighting. Two Camera Link frame grabber microEnable 5 marathon VCL trigger the four cameras on the sides.

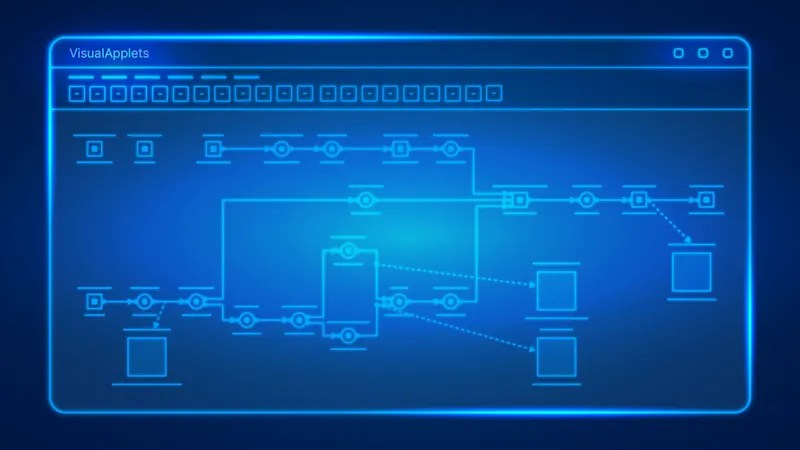

Delvitech developed recording functions using Basler’s VisualApplets graphic FPGA development environment for connecting the frame grabber to the software. As a result, the frame grabbers always generate the same output format as early as during the image transfer stage. This means that the software can continue to be used if the cameras, frame grabber or camera interface are changed.

Advantages of the vision solution for the inspection of electronic circuit boards

More powerful cameras and compatible frame grabbers enable the inspection of significantly more circuit boards per minute

Components can be flexibly exchanged and scaled

Thanks to the associated applet, the system can easily be adapted to new customer requirements

Products for this solution

Looking to implement a comparable solution? These products will help you.