Efficient Quality Control of Mini-LEDs by AOI

What quality control do mini-LEDs require?

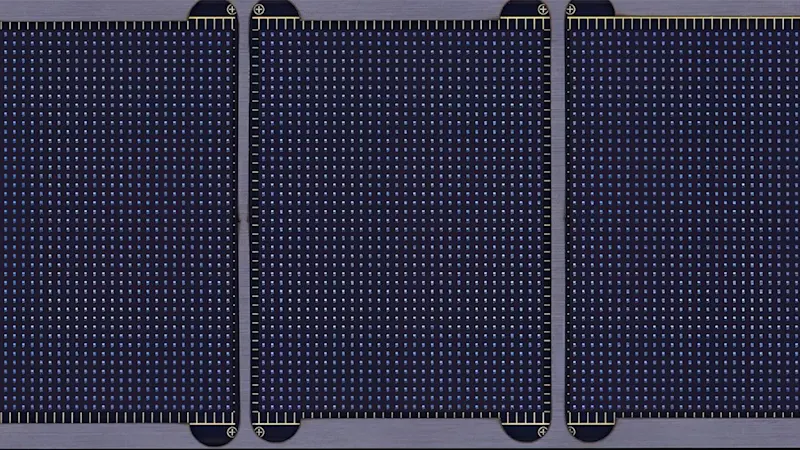

Mini-LED technology is becoming increasingly popular in both the direct view LED display and backlighting LCD display markets. Mini-LEDs promise improved display performance and visual appearance with greater efficiency and lower cost.

Mini-LEDs are manufactured in a complex process. Identifying defects and ensuring uniformity means inspecting every pixel.

Chinese company Mento uses Basler’s vision solution to develop complex AOI systems for visual inspection, defect detection and position recording for the quality control of mini-LED units.

Requirements for defect detection in the production of mini-LEDs

The inspection process needs precise information (e.g. defect coordinates) to locate and repair detected defects and reduce material waste in the production process.

In this display inspection application, high accuracy, stable performance and efficiency are therefore key.

The most important challenges:

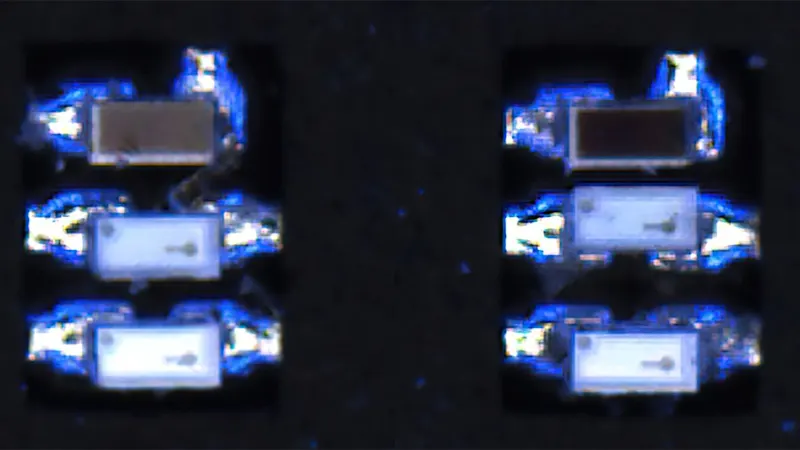

High resolution is required for small chip sizes (<100 µm) and spacing between bonds (<1.5 mm)

Multiple image stitching

High quality color image reproduction and image consistency

The vision solution for quality control of mini-LEDs

Visual inspection of mini-LEDs involves checking the bond joints, soldering quality and individual LED chips. The robust and reliable Basler ace 2 cameras with 20 MP resolution and an acquisition speed of 18 fps through the USB 3.0 interface are ideal for this purpose.

Basler customized and enhanced the in-camera features to better address key challenges like the requirement for high image quality and consistency while producing stable images. Based on this custom firmware solution, lens savings can be achieved to reduce system costs.

Different illuminations make it easy to distinguish the parts of the mini-LEDs under test.Together with the matching, robust USB 3.0 cable and the user-friendly pylon Software Suite, the system achieves its design goals within the given budget.

Benefits of the AOI solution with Basler vision components

Key benefits of the solution include:

Lower system maintenance cost owing to the powerful features and market-proven reliability of Basler vision products

Flexible and unique customization solutions to fulfill the requirements of a demanding application

Reduced system complexity thanks to the small camera footprint and convenience provided by USB 3.0 interface

Real-time inspection and recording of defects’ coordinates to improve production efficiency and yields

Products for this solution

Looking to implement a comparable solution? These products will help you.