Basler Products

Everything you need for your image processing system: a wide range of perfectly coordinated hardware and software components. So that you can implement your application quickly and easily.

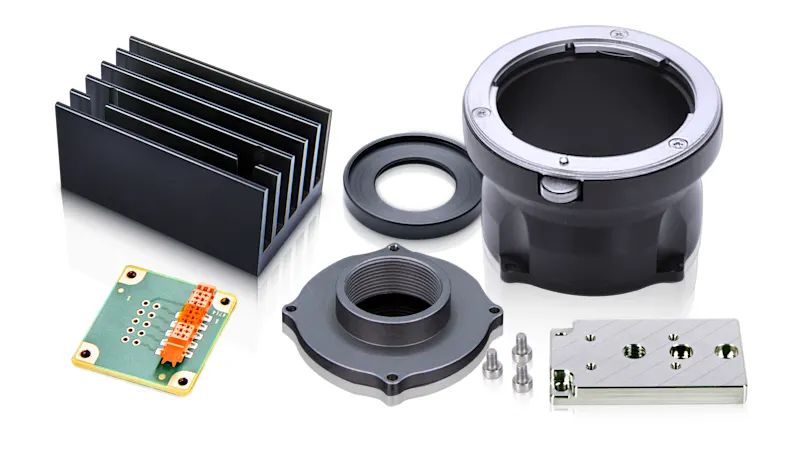

Computer vision hardware

All Basler products are quality-tested, reliable, and offer long-term availability with an excellent price/performance ratio. They can be used universally in all areas of industrial image processing.

Each product is tested not only for individual reliability and performance in computer vision systems, but also for compatibility and smooth operation with all other components. You can rest assured that all the components your image processing system will mesh seamlessly.

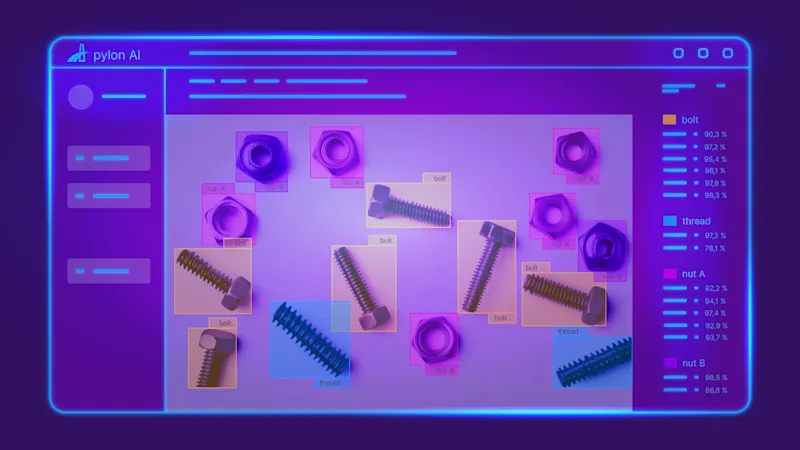

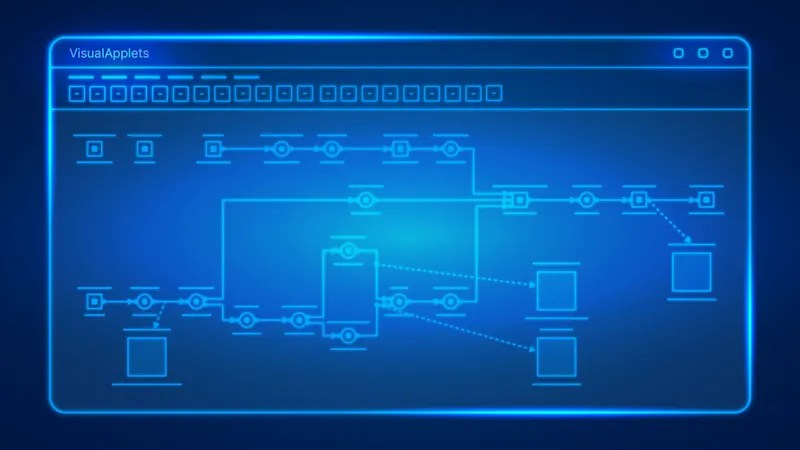

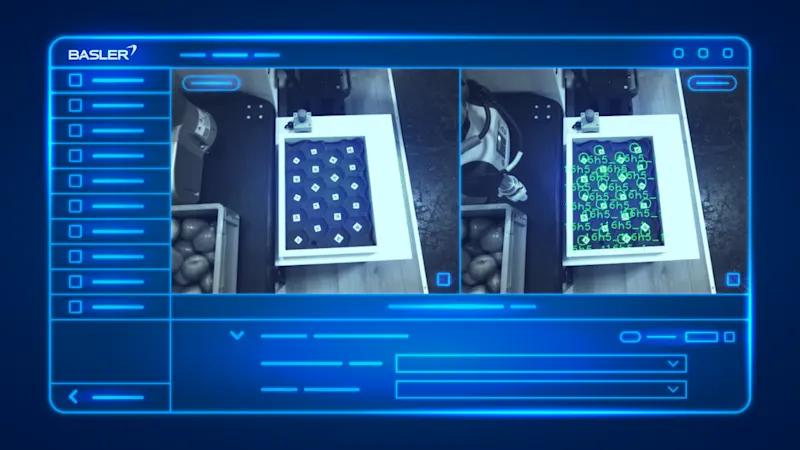

Computer vision software

The right software plays a decisive role in your computer vision solution. The Basler pylon software tools are optimally adapted to different application areas.

pylon enables you to quickly and easily commission your vision products and integrate high-performance image processing functions for your application—for seamlessly integrated image processing.