The Role of Computer Vision for Industry 4.0

Buzzwords such as Industry 4.0, the Internet of Things (IoT), the Smart Factory, Big Data, Digital Twin, and Artificial Intelligence all describe the increasing automation of production plants and the networking of a wide variety of systems. The goal: integrating information technology and thus computer vision into industrial processes as comprehensively as possible.

Vision systems for industry 4.0

Our white paper compares the smart factory setup of industry 4.0 to the classic factory setup of today. This reveals several advantages of the smart setup due to new technologies and requirements for the vision system of the future.

Vision systems as tireless process controllers and data suppliers

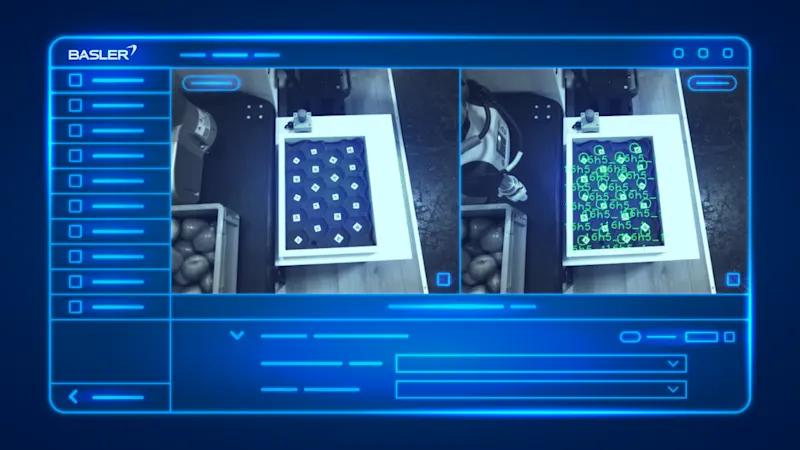

Analyzing camera data networked with production data optimizes production. Deviations such as bottlenecks, inefficiencies, and incorrect behavior of equipment can be automatically detected at an early stage and corrected in real time—including changing process parameters or replacing wear material.

Smart technologies for efficiency and safety

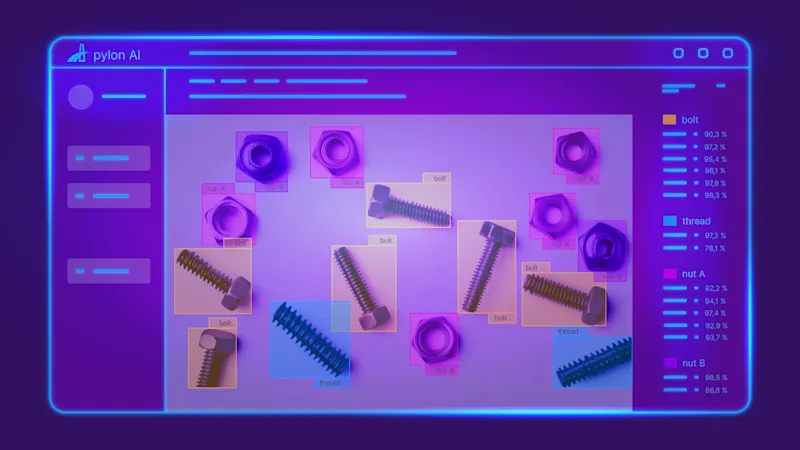

There are numerous applications for smart vision systems. Six key application areas show how these technologies are applied in practice and what advantages they offer:

Vision products for networked factories

Among the most important and powerful sensors in an automated factory environment are vision systems with cameras. They help to digitize production processes, increase flexibility, and successfully meet the challenges of industry 4.0.

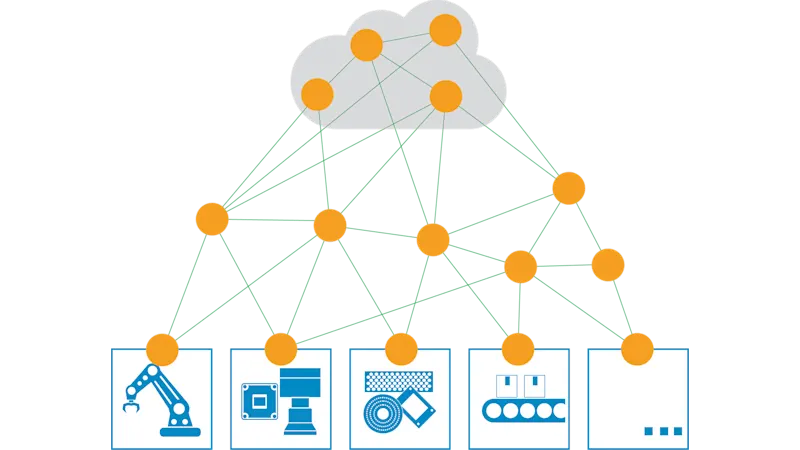

How data networking will make the factory of tomorrow smart

The term "smart factory" describes intelligent networking in the field of factory automation. Knowledge, consisting of data and processes, is a fundamental prerequisite for an intelligent factory. Where does this knowledge come from?

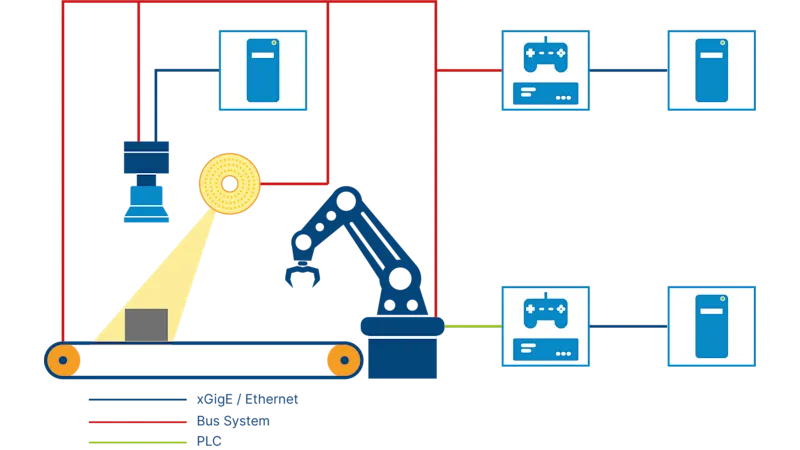

Classic factory setup with field bus systems

Data is usually collected using sensors, which also include imaging devices such as cameras. However, without appropriate processing, the data from the sensors is worthless. It must be made usable for several systems and components so that it can serve as a basis for decisions in processes. This is exactly where the factory becomes smart.

The secret lies in networking all individual and sub-systems involved. The basis of their networking is usually a so-called field bus system, which connects all sensors and actuators via the same data lines—both with each other and with an automation device, for example a control system (PLC).

Disadvantages of field bus systems in modern factory automation

In modern factories, subsystems and devices are often placed far apart. Therefore, real-time ethernet-based bus systems are often used because the ethernet standard is popular, provides low-cost hardware (such as cables and switches), and allows for long cable lengths between components. However, these systems have disadvantages:

Proprietary system landscapes: many real-time ethernet solutions are vendor-specific, making interoperability between different devices and systems difficult.

Limited semantic describability: the possibilities for describing the functions of components and subsystems in a clear and standardized way are often limited. This makes it difficult to integrate and maintain complex systems.

Networking thanks to umati and the OPC UA standard

Like all other subsystems, the vision system must be connected to all other systems and to the central control system, both in terms of hardware and software. This is done by means of special data exchange standards for industrial communication. These standards give the individual subsystems a common machine language, so to speak, to ensure easy interoperability. One of these standards is umati (universal machine technology interface). It uses OPC UA as an open, universal interface standard.

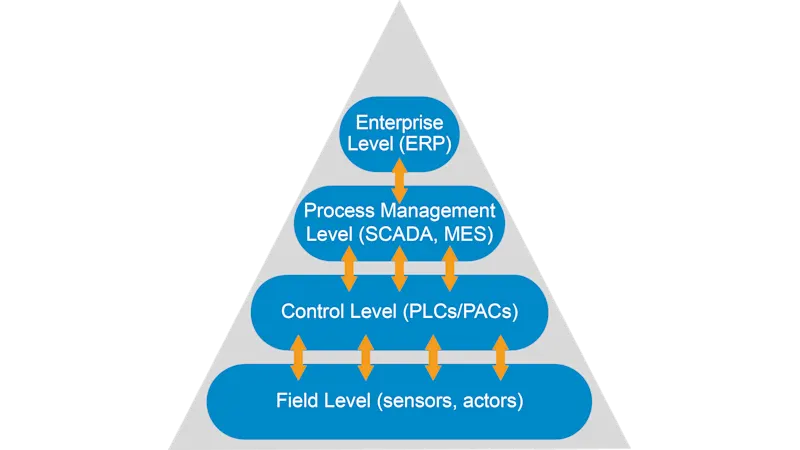

OPC UA makes machine data machine-readable and semantically describable. For example, the standard ensures the processing of sensor data and control commands, it specifies their transport, and determines the interfaces between systems and safety mechanisms. With the help of OPC UA, the different components on one level can be networked horizontally with each other as well as vertically across the different levels.

In industry 4.0, state-of-the-art technologies are expected to lead to significant increases in efficiency. To ensure that the complex technology in production remains easy to control, both standards and safety in the interaction of all system components are important. OPC UA offers both: simple and secure machine-to-machine protocols regulate communication and make the advantages of industry 4.0 usable.

Real-time capability in the networked factory

The OPC UA standard can be used at all levels of a factory setup: from the lowest field level (where the sensors and actuators are located) to the abstract information layers such as SCADA (Supervisory Control and Data Acquisition), ERP (Enterprise Resource Planning), or the cloud.

Real-time capability is indispensable in all areas of a smart factory. For this purpose, the standard offers expansion options such as Time Sensitive Networking (TSN). TSN aims to ensure data transmission over ethernet networks with very low latency and high availability. OPC UA TSN is also a prerequisite for transferring images directly from the vision system via OPC UA to other subsystems or the control unit.

OPC UA changes the classic factory setup

OPC UA can be used to save hardware components (such as PCs and controllers) and coordinate inconsistent, sometimes incompatible software. As a result, proprietary system landscapes from various subsystems are merged into highly integrated, leaner setups . A PLC or other host acts as the central interface of the systems, which now contains all subsystems respectively their software. This central node is in turn the interface to higher-level systems, such as ERP systems.

In such a setup, it would be possible to easily connect both the conveyor belt and robot, as well as the individual components of the vision system, using standardized transmission routes. With their PTP (Precision Time Protocol), the cameras already provide the basis for real-time capability when OPC UA is used as the standard and possible extensions such as TSN are available.