CCD vs. CMOS

Which Technology is Better Suited for Industrial Cameras?

CCD sensors were the most common image sensors on the market for a long time. However, the industry has continued to evolve and CMOS sensors have gradually taken over the market. In this text, we want to take a closer look at the differences between CMOS and CCD sensors and explore the sensor of the future.

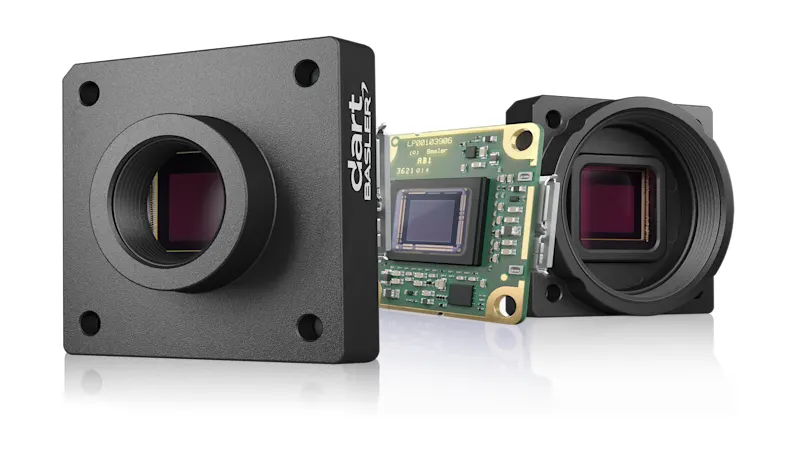

Modern CMOS cameras as a replacement for CCD cameras

In our White Paper, we explain the advantages of the new CMOS sensors over CCD sensors:

When should you think about changing your camera technology?

How do I choose the right successor camera?

What integration effort is required?

Modern CMOS sensors are often superior to CCD sensors

In March 2015, Sony announced the discontinuation of its entire series of CCD sensors. This heralded the end of new developments based on CCD technology in favor of CMOS sensors, which at the time were only inferior to CCD technology in a few respects. Over the last few years, new developments have allowed even those few disadvantages to be eliminated, allowing us to now enjoy the many benefits of CMOS sensors.

Of course, the comparison between CCD and CMOS sensors is not entirely accurate, as CMOS is now more than eight years ahead in terms of development. In the days when both sensor types were competitive, the decision of whether to use CCD or CMOS was based on the target application. Nowadays, the question of CCD vs. CMOS no longer arises, as CCD sensors are not being further developed. CMOS sensors have found their way into areas previously reserved for CCD sensors thanks to their high speed and resolution, low power consumption, as well as improved noise characteristics, quantum efficiency, and color concepts.

CCD vs. CMOS - the technical facts in detail

The improvements to CMOS technology and the strong price/performance ratio in these sensors make CMOS sensors increasingly attractive for industrial machine vision. In particular, the very high frame rates that can be achieved—almost without any compromise in image quality—are one of the primary hallmarks of the current generation of CMOS.

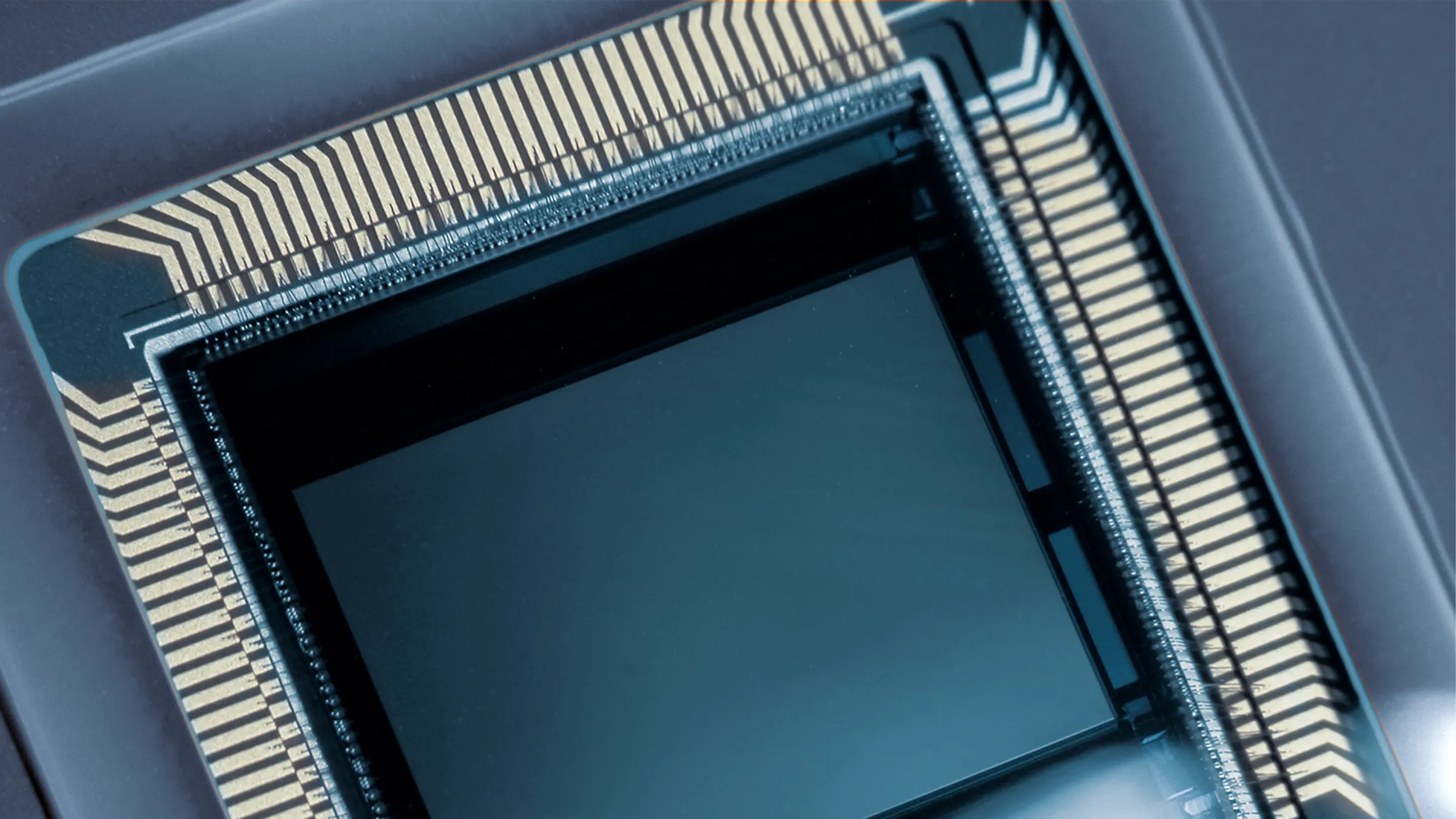

What does a camera sensor do?

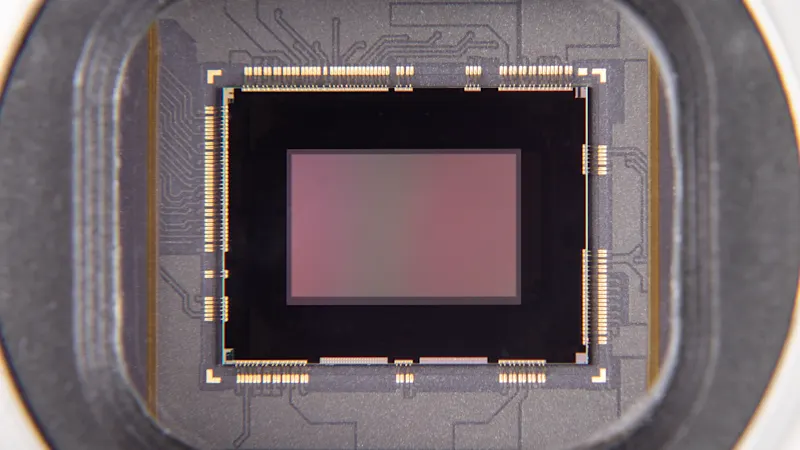

Both CCD (Charge Coupled Device) and CMOS (Complementary Metal Oxide Semiconductor) sensors convert light (photons) into electrical signals (electrons). The main difference between the two sensor types lies in their technical structure. In the CCD sensor, the charge is shifted per pixel. With the CMOS sensor, on the other hand, each pixel is read out directly.

Improved efficiency

In the past, CMOS sensors were significantly less efficient at converting the incident light. This has now changed. Further developments such as microlens arrays (which are applied to the chip) ensure that CMOS sensors now achieve the same or even higher sensitivities than CCD.

Higher frame rate

With CCD sensors, the readout speed is limited by the row-by-row or column-by-column readout. CMOS sensors, on the other hand, enable a significantly higher frame rate due to their architecture. Each pixel is read out individually, without the need to shift the charge as with CCD sensors. This means that the image information is read out much faster. As a result, performance can be increased, allowing, for example, more parts to be inspected per second or traffic violations to be better detected.

Greater dynamic range

The dynamic range of a camera describes the ratio between the strongest and the weakest signal that can be recognized above the noise in an image, i.e. the ratio of the saturation capacity to the sensitivity threshold. CMOS sensors often have a higher saturation capacity (i.e. the maximum number of electrons per pixel is higher), but are generally less sensitive. This means that the dynamic range of CMOS sensors often corresponds to that of CCD sensors. That said, the latest CMOS sensors—such as the Sony IMX174—are superior to all comparable CCD developments in terms of dynamic range.

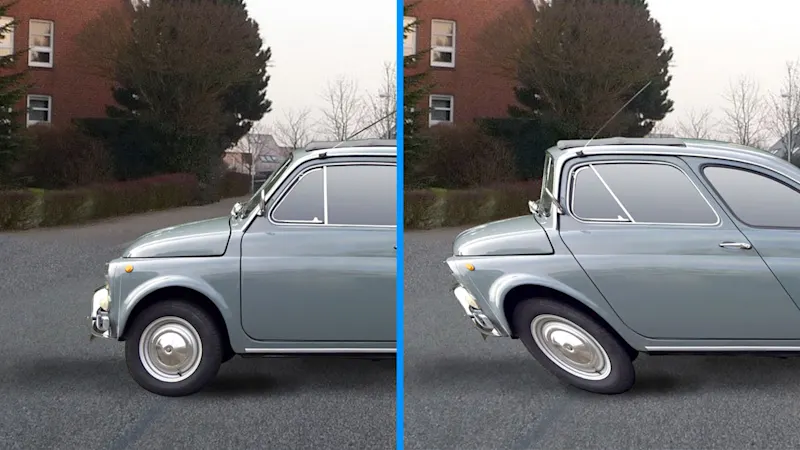

No "blooming" and "smearing"

CMOS technology has a clear advantage in bright light. If a CCD pixel is overexposed, the excess electrons generated "spill over" into the neighboring pixels. Very bright image structures then appear to spill over into darker ones or to "bloom"—which is indeed what this effect is called: "blooming". If the charges in the CCD sensor are transported in very bright light after exposure, bright stripes can appear in the image of the CCD sensor. White areas then appear smeared into lines in the image. This can be seen, for example, when a car with headlights drives towards the camera at night. This effect is called "smearing". CMOS has a significant advantage here: neither effect occurs with CMOS sensors.

No artifacts thanks to global shutter

The latest cameras with CMOS technology today are CMOS global shutter cameras, such as our ace 2 models with Sony's Pregius S sensor line or the PYTHON from onsemi. With these cameras, you are no longer exposed to the artifacts that occur in cameras with rolling shutters. Nevertheless, you should not categorically rule out a CMOS rolling shutter camera, as this may be more suitable for certain applications than a camera with a global shutter.

Modern CMOS cameras as a replacement for CCD cameras

We provide details on the switch to CMOS sensors in our free White Paper.

Questions that we answer in detail in the White Paper

When should you think about changing your camera technology?

How do I choose the right successor camera?

What’s important when integrating the latest CMOS-based cameras?

What integration effort is required?