Simple Tracking of Printed Circuit Boards with Basler racer GigE Cameras

- Customer

- Microscan

- Location

- Nashua, New Hampshire, USA

- Date

- 2013

Seamless traceability is crucial in modern electronics production - especially when processing multiple PCBs per panel. Microscan has developed a flexible solution for this with PanelScan, which relies on the proven quality of Basler racer GigE line scan cameras.

The challenge: barcode capture in the high-throughput process

With the miniaturization of electronic devices, such as smartphones and tablets, PCBs are becoming smaller and smaller. To increase throughput, manufacturers "panelize" printed circuit boards, meaning several printed circuit boards of the same type are printed on one large board. These boards then go through various stages of the manufacturing process before the PCBs are separated for final testing.

Each of these plates and circuit boards is provided with a unique barcode. However, the manual recording of these barcodes was error-prone and inefficient.

The solution: Automated barcode decoding for printed circuit boards

Thanks to its extensive experience in electronics manufacturing, Microscan has developed a turnkey solution to automate the decoding of barcodes on printed circuit boards. PanelScan is a user-friendly and easy-to-integrate tracking system for capturing barcode data. The integrated system replaces the error-prone manual scanning process with a solution that allows barcodes to be decoded on the fly and at full production speed.

PanelScan: Efficient barcode scanning

With PanelScan, all the operator has to do is enter the number of rows and columns of PCBs in the user interface, then place the panelized, coded boards on the conveyor belt.

The system automatically creates an inspection routine to read the barcodes at all defined positions.

For setup, a plate is fed through the camera unit. With a click on the "Teach Layout" button, PanelScan scans the plate and reads all barcodes. If a barcode is not decoded correctly, the operator can call up a high-resolution image of the corresponding area.

All recorded barcode data is automatically saved in a log file and is easily accessible at any time.

PanelScan with Basler camera technology

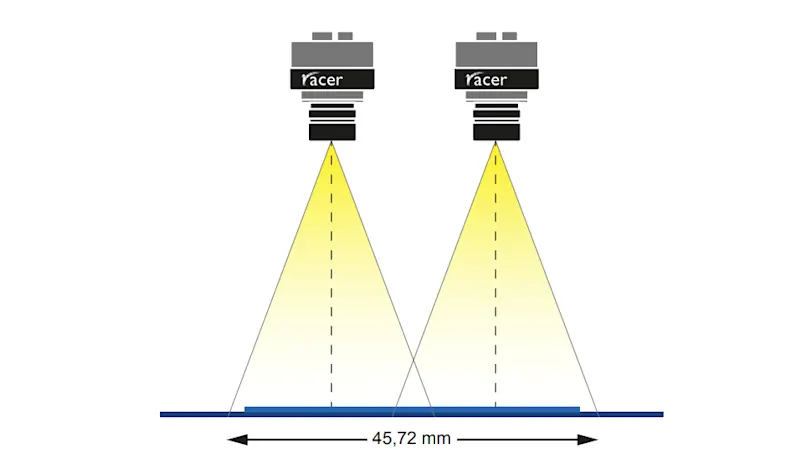

The central component of the PanelScan system is a line scan camera. In the standard configuration, a single camera captures panels up to 25.4 cm wide. For larger panels up to 45.7 cm, two overlapping line scan cameras are used in the wide format configuration to ensure reliable barcode decoding.

The cameras are mounted above the conveyor belt and capture images of the passing panels. Two focused line lights ensure optimum illumination, while a retroreflective sensor triggers image capture as soon as the front edge of the panel reaches the field of view. Image processing takes place on a separate PC.

Microscan chose Basler racer cameras because of their high performance levels, wide range of resolutions, and easy integration into our Visionscape machine vision software platform. These three points made the decision for racer cameras very easy.

Products used

Get this solution or a customized machine vision solution from us!

Our experts are happy to advise you on your individual vision project.

OMRON Microscan Systems

OMRON Microscan Systems, Inc. is a leading provider of automatic identification, vision, and traceability technologies for industrial applications. Originally founded in 1982 as Microscan Systems, the company was acquired by OMRON Corporation in 2017 and integrated into the OMRON Group. Headquartered in Renton, Washington, USA, OMRON Microscan combines decades of experience in barcode and vision technology with OMRON's comprehensive portfolio of automation solutions. The company provides innovative quality control, inspection, and traceability solutions worldwide that enable flexible and intelligent manufacturing.