Automated Optical Inspection (AOI)

Optical measuring systems inspect objects and detect a wide variety of features. With its large selection of area scan and line scan cameras, Basler offers the right model for every camera inspection task.

The importance of optical inspection in industrial image processing

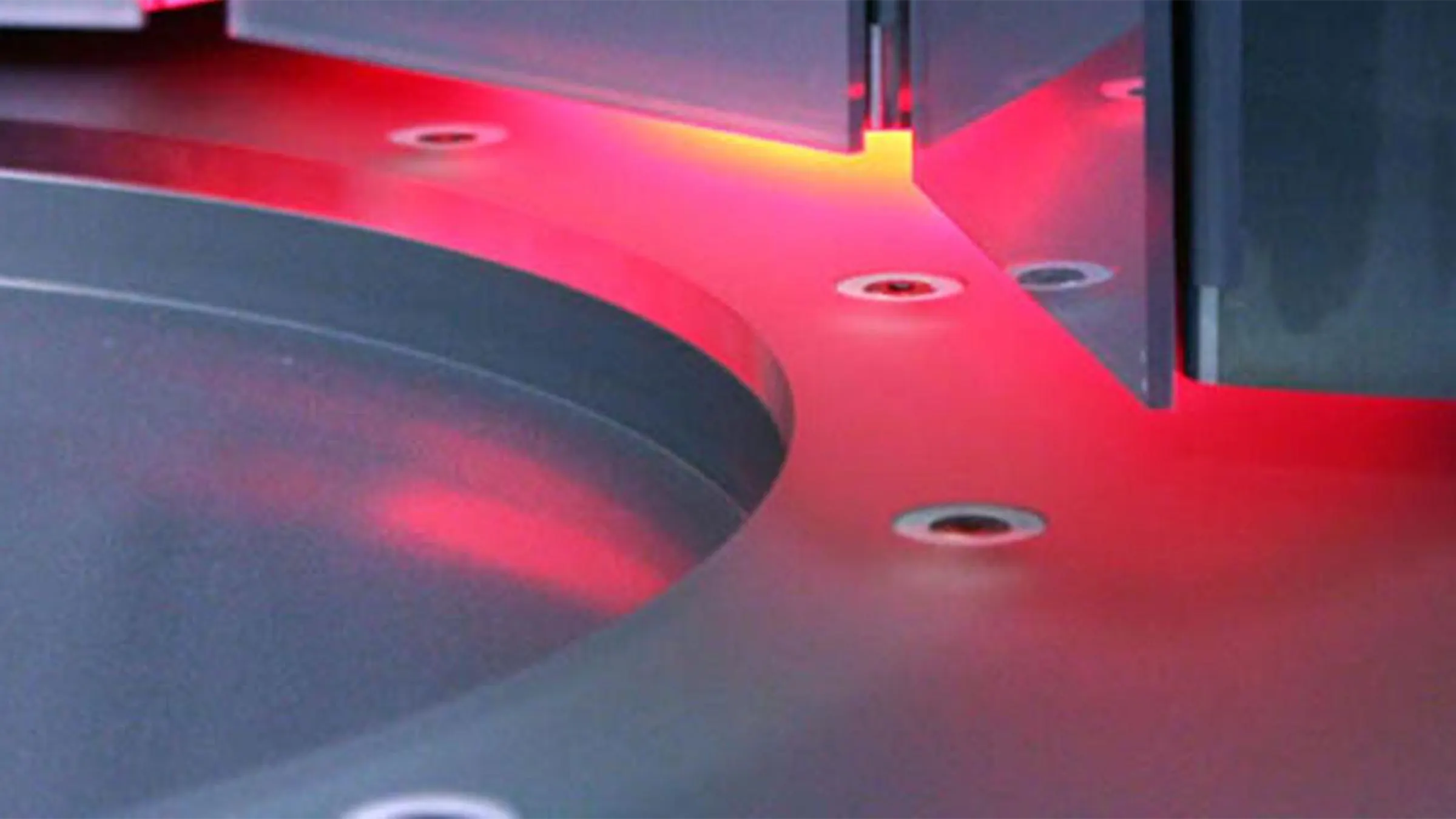

Optical inspection plays a role in the various fields of application for industrial machine vision. Whatever their specific area of use and requirements they face, all machine vision cameras have one shared mission: optical inspection. That means finding and identifying characteristics that serve as the basis for analyses and produce conclusions that can be used for ongoing processing.

Complex inspection tasks for measurement and error detection

Based on the identified characteristics, AOI systems can undertake optical measurements as dictated by the problem at hand and identify any deviations from the standards. Industrial machine vision is perpetually focused on so-called grayscale value deviation. The grayscale value indicates the brightness of a pixel, independent of color. Depending on how this grayscale deviation is configured, it is possible to

sort objects (foods, merchandise)

detect errors (scratches, entrapment)

measure sizes (packets, O rings)

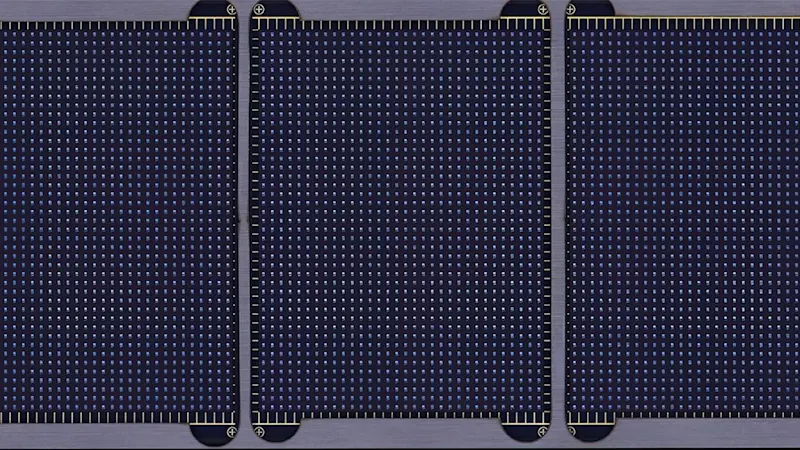

inspect surfaces (films, glass) or

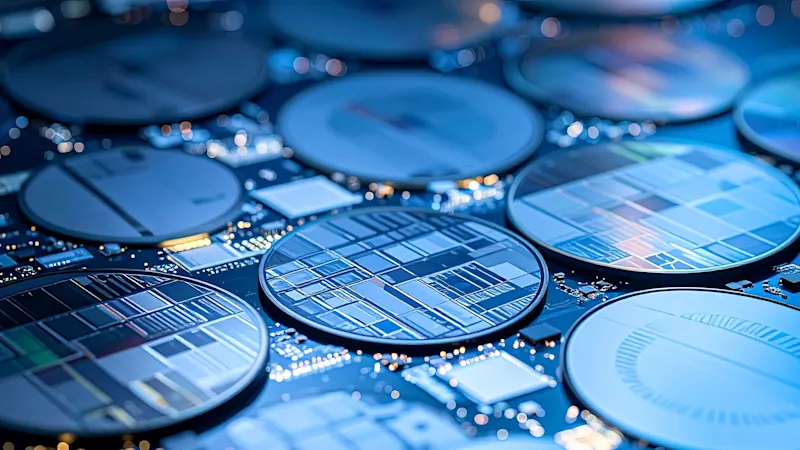

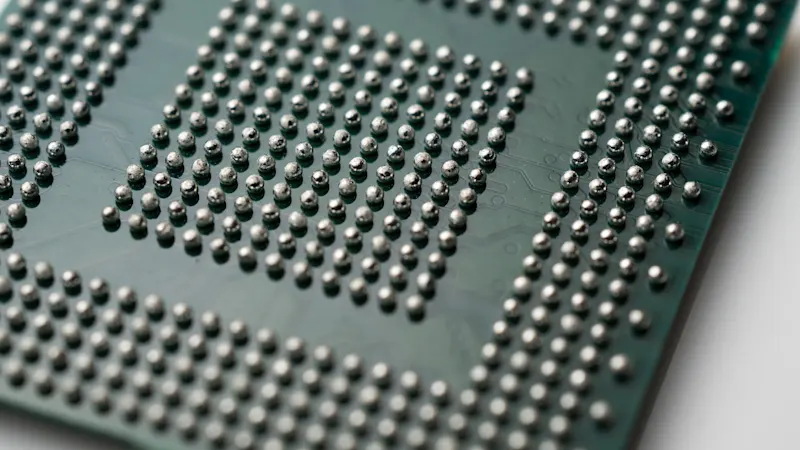

inspect circuit boards (for correct position of the solder points)

Application examples of Automatic Optical Inspection (AOI)

Find out more about our products and their applications. Our comprehensive information material provides you with all the important details.

Individual opportunities – flexible use

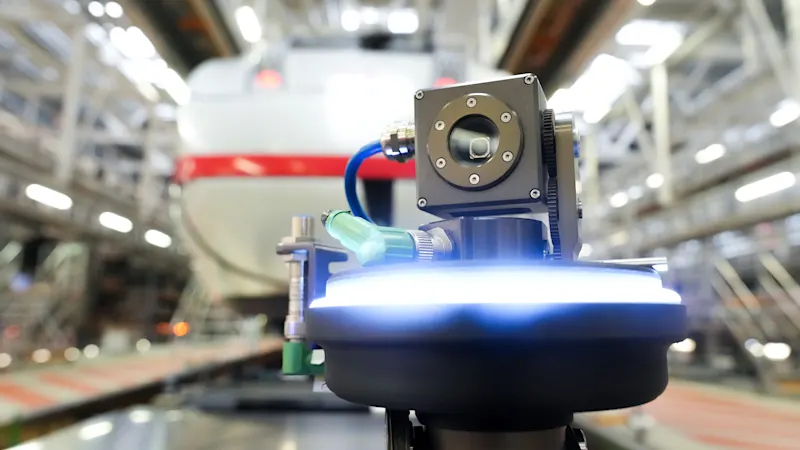

Automated optical inspection can be established at various spots in the production process to fit specific needs: Directly within production or as part of packaging, with 100% control or via trial-and-error testing. The use of powerful cameras with high frame rates allows for inspections to be run without disrupting the production workflow.

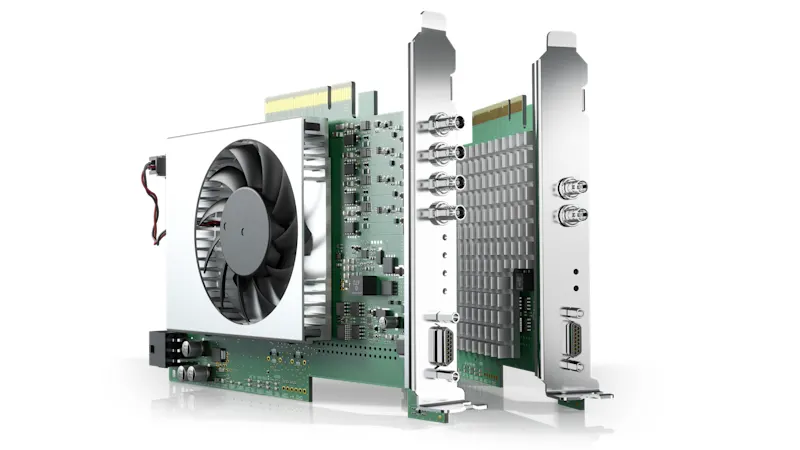

Necessary Components

The setup of optical inspection systems is multifaceted. The machine vision camera is just one of several components. Adequate lighting - artificial or natural - as well as a trigger, which is a signal in the form of a light barrier or encoder that essentially cues the camera, are other indispensable hardware components.

Image preprocessing, such as code detection, runs on the FPGA of the VisualApplets platform (e.g., in the frame grabber or on the camera). During this process, a region of interest is defined so that only the relevant image areas are transmitted. This reduces the data volume and transmission time. The preprocessed image data is then transferred via the camera interface to the computer unit, where it is further processed and evaluated by the analysis software.

Image Analysis Software for Automated Optical Inspection

For automated optical inspection (AOI), our software add-ons, the pylon vTools, offer an extensive selection of powerful modules.

A robust and precise choice are the AI algorithm-based pylon AI vTools. In particular, Anomaly Detection and the two Segmentation vTools (Instance Segmentation & Semantic Segmentation) are optimal for defect detection/deviation analysis for quality assurance.

Additionally, the Code Reader vTools such as QR Code Reader Pro, Barcode Reader or Data Matrix Code Reader are suitable for fast and reliable product tracking.

For classic AOI tasks, tools like Template Matching, Geometric Pattern Matching and Color Blob Analysis are available – they enable robust defect detection, object and shape identification, as well as sorting and inspection processes. The vTool Measurements module provides precise measurements of distances and dimensions for quality assurance.

To the pylon vTools