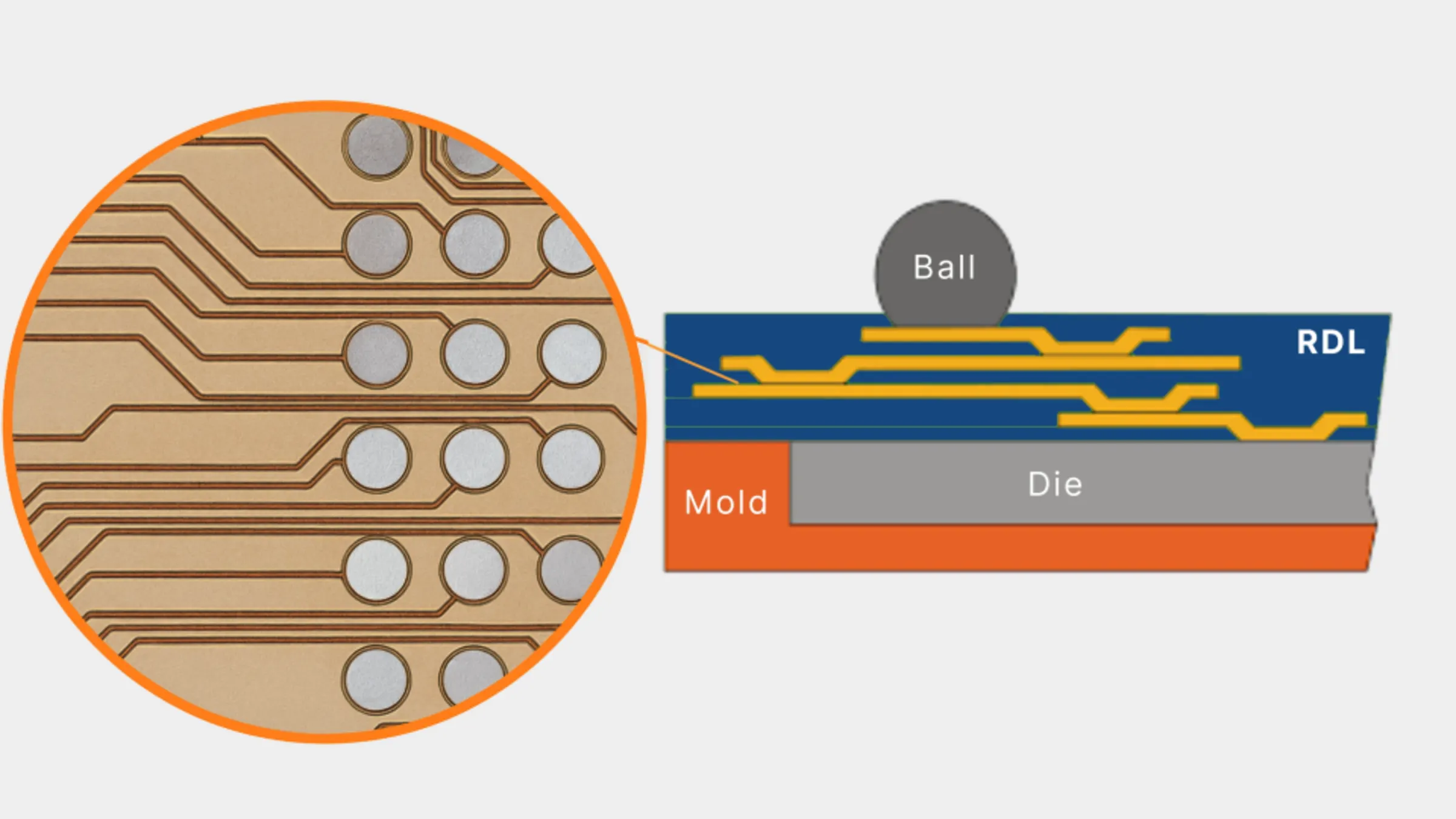

High-speed 2 µm Redistribution Layer (RDL) Inspection

Overcoming vision challenges in advanced packaging

With the rising cost of Known Good Dies (KGD), defect detection and false positive control in Redistribution Layer (RDL) inspection have become critical in the back-end process. As copper RDL linewidths shrink to 2 µm and below, multi-material layer stacking induces substrate warpage, significantly increasing inspection complexity. This directly impacts yield, cost control, and time-to-market. This case study presents a cost-effective, high-speed, line-scan vision solution for RDL inspection.

Application requirements for modern RDL inspection

High-density RDL is a core interconnect technology in advanced packaging, widely deployed in FOWLP, FOPLP, 2.5D and 3D silicon or glass interposers, as well as HBM and chiplet packages. These applications impose unprecedented demands on dimensional accuracy and reliability. Current mainstream RDL technology has advanced to 2/2 µm or smaller dimensions, with 4–5 copper layers now common in fan-out packaging, and even more in leading-edge processes.

Multi-layer structures add inspection complexity, with challenges such as substrate warpage, copper grain noise, and the large data volumes generated by high-resolution scanning. These factors demand precise, consistent imaging for every RDL layer.

Tackling key vision challenges in RDL inspection

Resolving ≤2 µm features at production speed

Nyquist sampling requires about 0.87 µm/pixel resolution to clearly separate adjacent copper lines in 2/2 µm RDL patterns. While this provides ideal image quality, the high magnification reduces field of view and increases scan time.

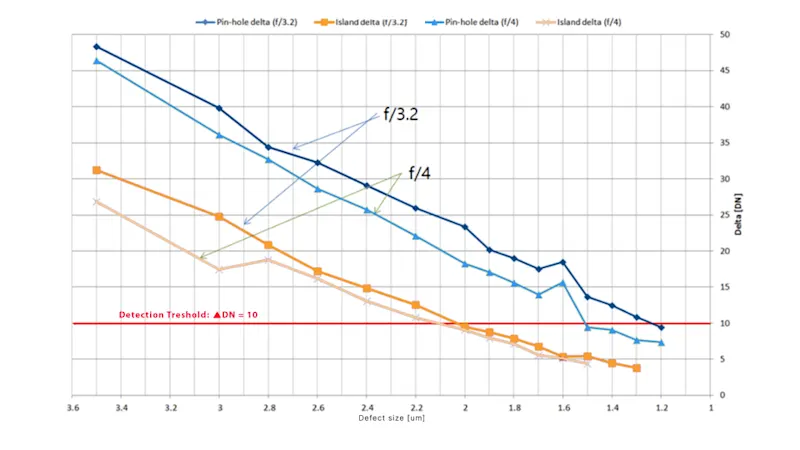

A more practical alternative is single-pixel detection, where the smallest critical feature is covered by a single pixel, and detection is based on the pixel’s grayscale delta (ΔDN). For example, with 3.5 µm * 3.5 µm pixels and 1.75× magnification, the object-side resolution is 2.0 µm/pixel, allowing direct inspection of 2 µm RDL features. By quantifying the relationship between feature size and grayscale difference, and setting an appropriate detection threshold, defects can be sperated from background.

As shown in the line graph, at f/3.2 aperture, black dot defects (pinholes) can be detected down to 1.2 µm, and white dot defects (islands) down to 2.0 µm.

Looking to improve your RDL inspection? Talk to our expert.Our customers face many trade-offs in 2 µm RDL inspection — resolution vs. speed, defect sensitivity vs. false calls, DOF vs. warpage, and data volume vs. inline requirements. We help shorten their trial-and-error process by reviewing AOI system constraints, production targets, and sample data, then providing practical tests and recommendations on lens NA, illumination, and preprocessing. This consultative approach enables faster, more confident integration of the right vision setup.

Continue reading: Practical vision design strategies for 2 µm RDL inspection

Submit the form to access the remaining sections on multi-layer RDL inspection challenges, image consistency, and system-level vision solutions.