AI Quality Inspection of Aluminum Cans

Precisely detect number of pieces, anomalies, and position in real time

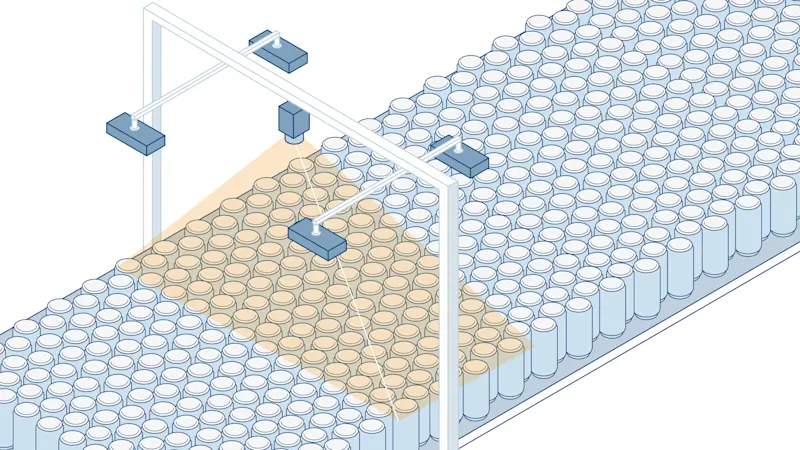

The pylon AI software modules intelligently automate quality control in aluminum can production. The vision system detects the cans on the conveyor belt, recognizes and counts them, and monitors production progress and rejects. The AI recognizes fallen cans based on their position and identifies anomalies such as dents or deformations. This creates maximum transparency and efficiency in the production flow.

Smallest defects, reflective objects, and high throughput

Several challenges come together in can production lines: reflective aluminum surfaces, high object speeds, and the need to reliably detect even the smallest defects. This is precisely where the combination of pylon AI software and a robust IP67 vision system becomes valuable.

Details: smallest defects

The smallest defects (such as dents, scratches, or deformations on the underside of the can) must be reliably detected by the vision system in order to ensure product quality. Especially at high line speeds, it is crucial that even minimal deviations are detected in real time so that defective cans can be reliably rejected.

Aluminum

The smooth surface of the aluminum strongly reflects incident light rays. These reflections create bright spots in the image. Optimized lighting and camera settings minimize these reflections, ensuring reliable and precise image analysis.

2,000 cans per minute

After washing, the cans are moved on a 3 m wide mass conveyor belt. Depending on the type of system, can size, and line configuration, modern production lines achieve a throughput of 1,200 to 2,000 cans per minute.

Extracting all important information with AI software

The pylon AI software detects defects such as dents, identifies fallen cans, and reliably counts the cans–both throughput and rejects. This creates full transparency, high product quality, and automated inline process control.

Reliable detection of all cans on the mass conveyor belt

To ensure efficient batch production, it is essential to record the number of cans produced. This makes it possible to determine exactly when the desired quantity has been reached - and reliably avoid over- or underproduction.

In the first step, with the help of Object Detection all cans on the conveyor belt are detected- regardless of whether they are standing or lying down. In this way, the cans can also be counted. The triggering of the camera must be adapted to the speed of the conveyor belt so that the frames do not overlap and cans are not counted twice.

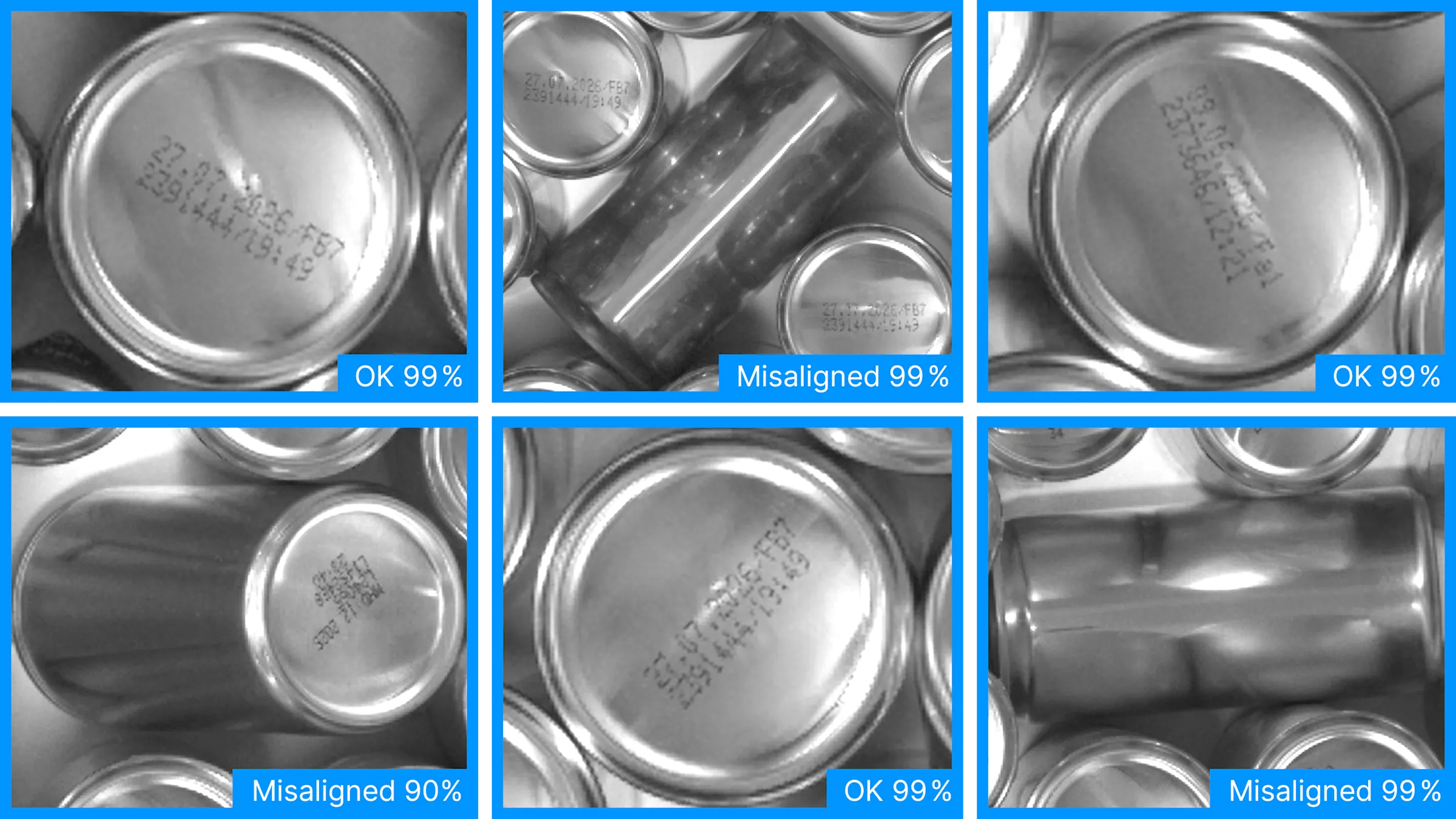

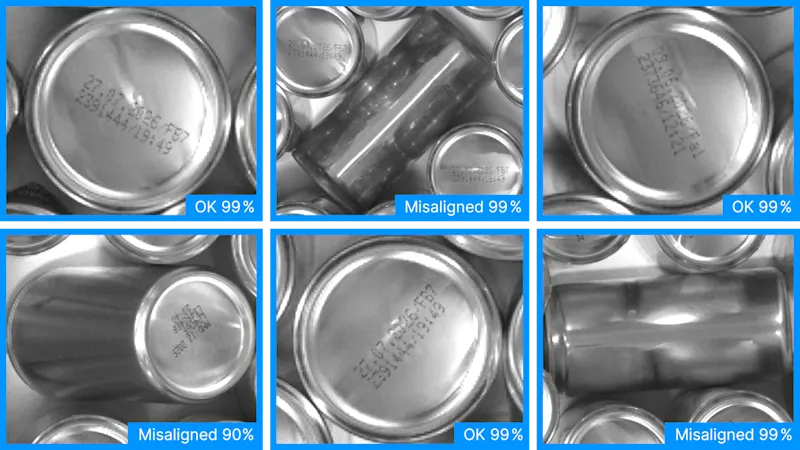

Inline process control: Detecting the orientation of the cans

With the help of monochrome area scan cameras and pylon AI, the IP67 vision system can detect whether the cans are upright. Misaligned or fallen cans are detected in the second step using the pylon AI add-on Classification. To do this, each individual can previously recognized as a can is classified as "OK" or "Misaligned".

The coordinates detected by Object Detection are transmitted to robots. The robots can then grip and erect the cans in a targeted manner before they are forwarded to critical downstream processes, such as drying, coating, or printing.

100% flawless cans: precise detection of anomalies

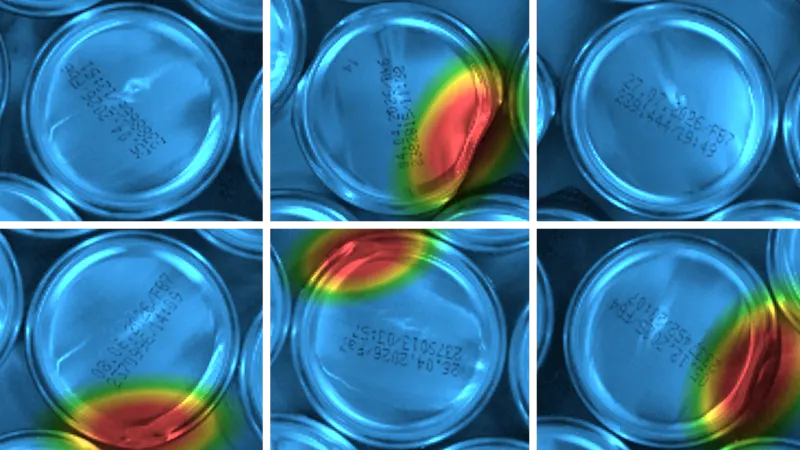

The final processing steps leading up to delivery-ready cans require cans free of any defects. To ensure this, the pylon AI add-on Anomaly Detection is used to inspect the bottom of each individual aluminum can.

The heat map shows regions with conspicuous model deviations. Red areas mark potential anomalies that may be caused by defects or material irregularities, for example. A threshold value helps to classify an image as "defective" or "in order".

Accurate batch production thanks to inline can counting

The pylon AI add-ons enable precise can counting in real time - even at conveying speeds of up to 2,000 cans per minute. The recorded data can be integrated directly into MES (Manufacturing Execution Systems) or WMS (Warehouse Management Systems), supporting precise inventory control and efficient changeover planning.

Depending on requirements, two counting methods are available:

All cans on the belt are recorded, regardless of whether they are lying down, stationary or defective. The rejects are deducted downstream.

Only the perfect cans are counted after defective cans have been sorted out and tipped over cans have been righted.

Are you interested in the image processing recipe of this sample application or would you like to implement a similar application with us?

Request nowAI learns from image examples and automatically recognizes relevant features in the captured images - ideal for complex or unstructured applications. The advantage over conventional algorithms is particularly evident in the case of diverse permutations, such as fallen cans: AI delivers robust results where defined rules reach their limits.

IP67 vision system for the quality control of cans

The IP67-protected vision system made from compatible components delivers reliable images under demanding conditions with dust, dirt, and water.

Quality control in can production–even under demanding conditions

Our vision system and intelligent pylon AI software offer a powerful solution for inline inspection after the washing process. The system reliably detects dents, deformations, and horizontal cans - even on moving objects with reflective aluminum surfaces at high throughput rates. By continuously counting the cans, it also provides basic information about the manufacturing process.

AI-supported anomaly detection

AI-supported alignment detection of cans

Inline batch quantity counting

Optimized image quality: Robust vision system with IP67 components for environments with steam and moisture

In this way, the system ensures quality and process reliability–efficiently and individually adaptable.