Automated Quality Control for Varying Object Sizes

Line scan cameras used in flexible manufacturing

Line scan cameras, such as the Basler racer 2 S, enable the inspection of fast-moving objects with different lengths and widths. Using suitable trigger settings, each object can be precisely captured within an image - a so-called frame with up to 12,000 lines. This enables efficient quality control even in highly flexible production lines.

Application areas with varying object sizes

Line scan cameras are used whenever maximum resolution along the direction of movement is required. Their strengths are particularly evident when it comes to imaging varying object sizes.

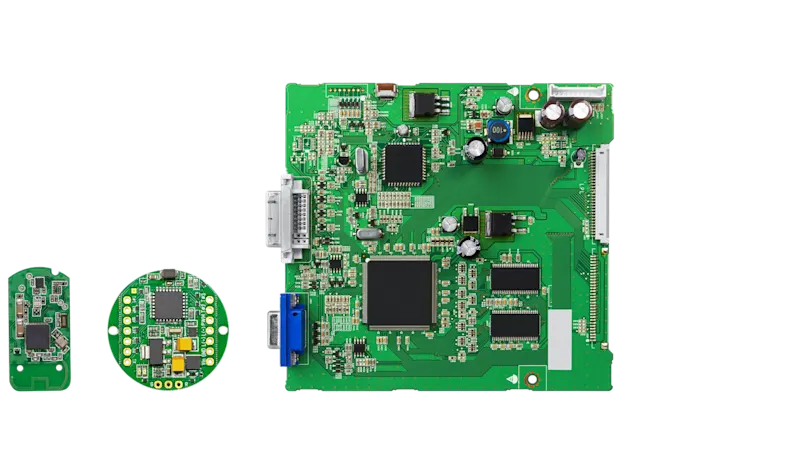

PCB inspection

Different PCB formats

Pick-and-place machines or soldering systems are designed for changing PCB formats and designs. Line scan cameras dynamically generate frames with a variable number of lines, enabling precise, format-independent inspection.

CNC metal processing

Geometric diversity

Components with different geometries are produced in modern CNC-controlled turning and milling machines. Line scan cameras enable precise in-process or end-of-line inspection - regardless of the size or shape of the components.

Cylindrical objects

Label or print image control

Bottles and cans often vary in diameter - and therefore also in the size and position of their labels or prints. Line scan cameras enable seamless quality control in the labeling or printing process, regardless of the object format. Duplicate images of object areas are reliably avoided.

Continue reading the Use Case

Fill out the form to read the full use case. The content is available immediately after submitting the form.