Brilliant Color Quality Thanks to Precise Inspection with Basler racer GigE Cameras

- Customer

- Boulder Imaging

- Location

- Louisville, Colorado (USA)

- Date

- 2013

Every detail counts for consistent, flawless coatings. Boulder Imaging relies on Basler racer GigE cameras to perform grinding analyses reliably, repeatably, and objectively - a decisive step toward quality assurance in the paint and coatings industry.

Quality assurance begins in the grinding process

Powders are essential components in many coatings, such as paints or lacquers - their quality directly influences the end result. These powders are produced by grinding processes, the precision of which is crucial for a uniform, flawless surface. After all, no coating is better than its weakest particle.

Uniform distribution of the ingredients is only ensured if the grinding is precise, repeatable, and documentable. Particles that are ground too coarsely or too finely can lead to production losses, reworking, and higher costs.

Grinding gages are used to check the grinding quality. These measure the degree of fineness and the homogeneity of dispersions, i.e. the particle distribution in liquids. However, the evaluation is often carried out manually - that is, subjectively and without the possibility of subsequent verification. Standardized tests usually involve ignoring outliers and recording a value once before the sample is discarded.

This is precisely why there is a great need for an objective, automated system: for more control, traceability, and consistent quality in industrial coating.

Automated grinding analysis for consistently high quality

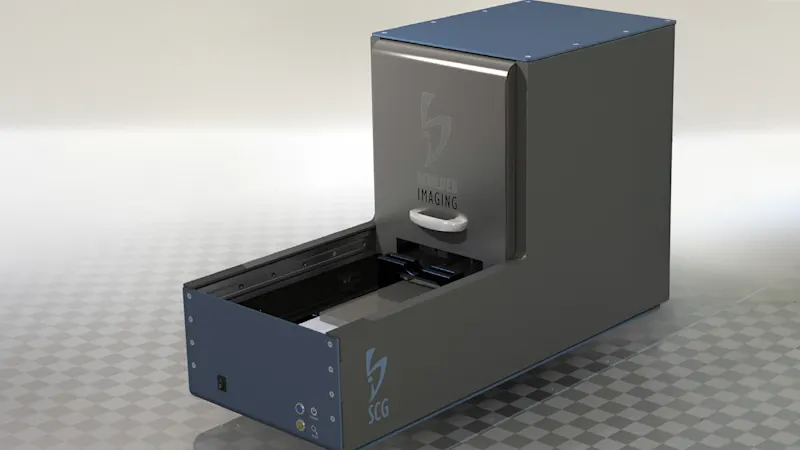

As an alternative to subjective grinding analyses, Boulder Imaging developed a fully automated SCG series grinder inspection system that automatically distributes (or "subtracts") a pigment dispersion in a very uniform manner. The SCG then provides accurate, repeatable, and retrievable grinding analysis that is independent of the human operator, eliminating subjectivity in grinder inspections.

SCG system: Fully automated inspection process

The SCG automates every step of the process, from the extraction of multiple, repeatable samples to time-accurate image acquisition and algorithmic static analysis of particle size. Even after the physical sample has been discarded, the captured image data and analysis remain digitally available for later inspection, comparison, and documentation.

Versatile application possibilities with Basler racer cameras

Initial target markets for the SCG are manufacturers of coatings and inks, followed later by industries such as cosmetics, adhesives, colorants, resins, and food.

Basler's line scan cameras from the racer series are used in Boulder Imaging's SCG for the inspection task.

The Basler racer series delivers excellent image quality at a wide range of resolutions and offers both a GigE and a Camera Link interface, making it the right choice for the SCG series. The compact size and industrial design have made it the perfect solution for Boulder Imaging's product.

Products used

Get this solution or a customized machine vision solution from us!

Our experts are happy to advise you on your individual vision project.

Boulder Imaging

Boulder Imaging is a provider of high-precision image processing solutions for industrial applications. The company develops high-performance systems for automated inspection and analysis - with a focus on reliability, speed, and individual adaptation to complex requirements.