Area Scan Camera Sorts Wood Veneers in a Line Scan Application

- Customer

- MJV-Sähkö Oy and Lateral Engine Oy

- Location

- Lahti, Finland and Espoo, Finland

- Date

- 2019-2020

With the Basler boost CoaXPress 2.0 camera and the CXP-12 Interface Card 1C, Finnish companies MJV-Sähkö Oy and Lateral Engine Oy have realized a high-performance image processing solution for industrial veneer sorting.

Image processing systems for industrial veneer sorting

MJV-Sähkö Oy supplies parameterizable vision systems for sorting veneer panels for the plywood industry. In their automation projects, including veneer sorting, it is important to work with efficient and modern automation systems in order to achieve high productivity.

The challenge of industrial veneer sorting

Traditionally, the line scan cameras used to automatically classify veneer are complex to install. Therefore, MJV-Sähkö Oy was looking for a color area scan camera that not only met the requirements for the veneer grading inspection process, but was also easy to install.

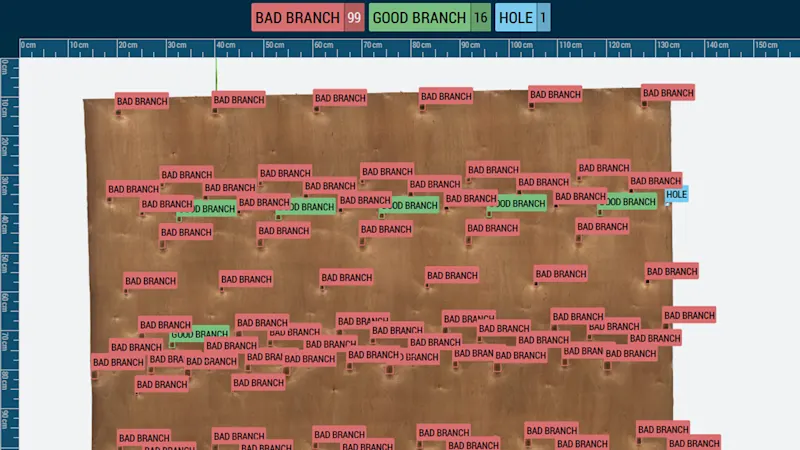

Precise classification of veneer sheets through deep learning

During veneer sheet sorting, images of the veneer sheets (e.g. 1800 mm wide) are taken on a conveyor belt with high-resolution line scanning. Software then analyzes the image data using modern deep learning methods. The results can be used by the production system for various purposes, e.g. to separate the sheets into different qualities or to assemble the material.

Solution with Basler boost

The solution utilizes the Basler boost CoaXPress 2.0 camera (boa4096-93cc). It is combined with a specially developed Basler CXP-12 Interface Card 1C. This custom interface card enables easy, compact, and reliable integration of the camera into the existing system.

A smart combination for greater efficiency

Thanks to the high data rate of CoaXPress 2.0 (12.5 Gbps), the frame rate at the highest resolution is significantly higher than with previous systems. Cabling and integration have been simplified, reliability increased, and the total cost of ownership reduced.

There is nothing revolutionary about line scan camera applications, but the novelty of this implementation is how we chose an area scan camera instead of a line scan camera in close consultation with Basler. The basic idea is to configure the camera and interface card in such a way that the area of interest (AOI) is limited to just a few lines, allowing a very high frame rate to be achieved (e.g. 4 lines at 2000 Hz, triggered by an encoder interface). The line blocks are then efficiently stitched together in the interface card before the complete images are transferred to the host software.

The advantages at a glance

Precise image quality thanks to the Basler boost camera's high-resolution CMOS sensor

High bandwidth with CoaXPress 2.0 - thanks to the combination of Basler boost camera and Basler CXP-12 Interface Card

Cost-effective complete package: Basler boost bundle with matching interface card

Long cable lengths of up to 40 m with a bandwidth of 12.5 Gbps

Inexpensive C-mount lenses are used - without sacrificing quality

Simple integration

Flexible use of the entire sensor

Freely selectable AOI (Area of Interest)

Significantly less installation effort compared to conventional line scan cameras

Extended interface card in collaboration with Basler - offering line stitching and encoder trigger functions.

Products used

Get this solution or a customized machine vision solution from us!

Our experts are happy to advise you on your individual vision project.

MJV-Sähkö Oy & Lateral Engine Oy

The companies MJV-Sähkö Oy and Lateral Engine Oy , based in Finland, offer complete solutions in the field of factory automation. They work closely together to create sophisticated image processing systems - for example for sorting wood veneers.