Reliable Shear Edge Detection in High-Speed Glass Bottle Inspection

Solving the industry’s most challenging defect with advanced vision design

Shear edges are among the most challenging defects in glass bottle inspection—microscopic, nearly invisible, strongly directional, and easily mistaken for thread reflections. This use case examines how advanced optical design, multi-angle illumination, and high-speed imaging architectures enable reliable detection of these critical finish defects in modern production lines.

Last updated: 01/19/2026

Why shear edge detection is the hardest finish-region problem

Shear edge detection is uniquely challenging because the sealing rim concentrates multiple optical difficulties into a single, microscopic region. Unlike body or base defects, shear edges reveal themselves only under narrow illumination angles and can be easily overshadowed by the geometry of the finish itself. At production speeds that often exceed 300 bottles per minute, even slight variations in lighting stability, viewing angle, or bottle rotation can cause the defect to disappear entirely. This makes finish inspection highly sensitive to optical design and synchronization. To achieve consistent detection across bottle types and line speeds, modern AOI systems rely on high-resolution cameras, multi-angle illumination, and finish-specific algorithms engineered for this exact task.

Finish-region challenges affecting shear edge detection

Shear-edge detection concentrates multiple optical obstacles into a single region—the sealing finish.

Challenge | How it affects shear edge detection | Solution |

Low Contrast | Thin transparent fin blends into the sealing rim. | Low-angle darkfield lighting and high-resolution global-shutter cameras to enhance contrast. |

|---|---|---|

Thread reflections | Threads create bright helical reflections mimic fins | Multi-angle lighting+ rule-based masking or AI classification to suppress thread reflections and prevent false alarms. |

Mold seam interference | Vertical seams misinterpreted as cracks/fins | Seam localization + classification |

Directional visibility | Defect disappears when lighting angle shifts | Three-camera layout with staggered lighting angles to ensure at least one valid view. |

Specular glare | Glare bands saturate pixels, hiding defects | Polarization, diffuse lighting, slight camera tilt |

Vision solution for accurate shear edge detection

To achieve reliable shear-edge detection at high throughput, the inspection solution typically apply three complementary pillars:

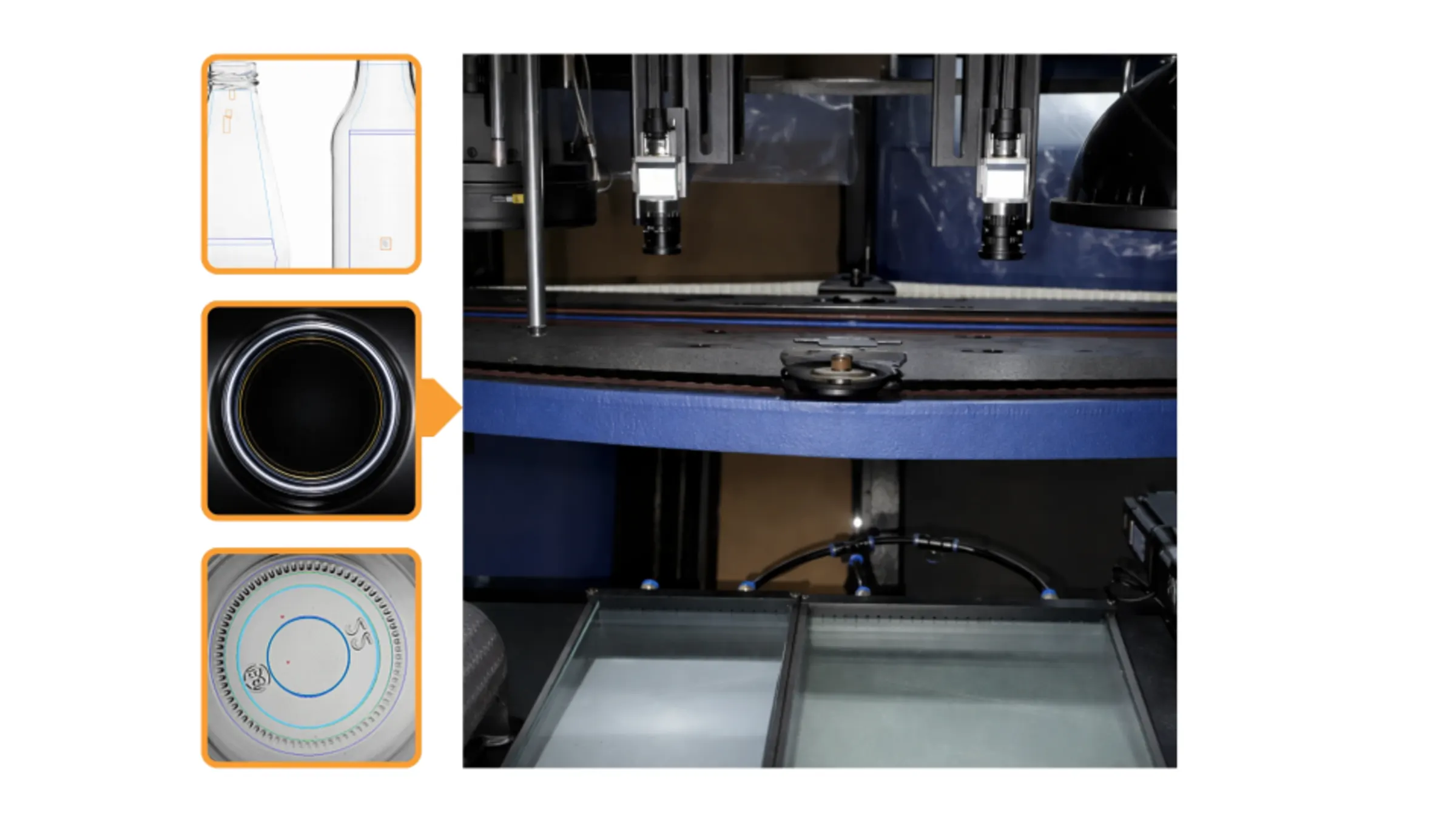

1. Multi-camera architecture for glare-free finish coverage

A three-camera side-view arrangement surrounds the rotating bottle to eliminate blind spots caused by glare.

Because glass acts as a convex mirror, glare bands often obscure the finish; multi-view imaging ensures at least one camera maintains a clear view.

High-resolution global-shutter Basler cameras capture pixel-level detail needed for micron-scale fin detection.

In high-speed inspection systems operating at 250–300 bottles per minute, a full AOI line may deploy over 30 cameras with multiple illumination units distributed across body, finish, and bottom inspection stations.

Depending on the inspection task, light sources may be triggered individually or in combination, and customized camera I/O signaling ensures optimal illunimation timing without adding complexity.

Need synchronization at scale? Talk to our vision experts.2. Specialized illumination geometry for high-contrast rim imaging

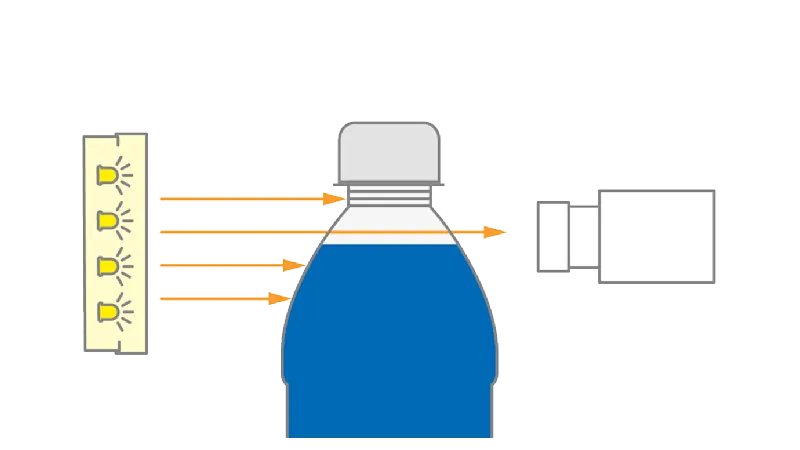

A multi-angle darkfield ring or dome forces the shear edge to “glint,” enhancing contrast while suppressing thread reflections.

Backlight and darkfield images are captured in an encoder-synchronized multi-flash sequence, ensuring the bottle has not rotated between flashes. This yields clean silhouettes for metrology and high-contrast rim images for defect detection, even at high speeds.

3. Mechanically stable, high-speed imaging platform

Rigid mounts, vibration damping, and fixed working distances (150–300 mm) preserve edge sharpness.

Micro-vibration can blur the rim region—where shear edges may be only a few microns wide—making mechanical stability essential for consistent detection.

Enclosed light tunnels block ambient factory light and maintain repeatable illumination.

Shear-edge detection is one of the most challenging inspection tasks and demands precise lighting geometry. We also see customers struggle with seams being misread as checks, glare-induced blind spots, and contrast shifts when switching from clear to amber or green bottles. With controlled illumination geometry and synchronized global-shutter timing, tricky defects became reliably visible and overall defect classification far more stable across all SKUs.

Summary

Shear edge detection remains one of the most demanding AOI challenges due to the combination of transparency, finish-region geometry, glare behavior, and strict illumination requirements.The most reliable systems today integrate:

Multi-camera viewpoints for glare-free rim coverage

Optimized darkfield and diffuse lighting

Hybrid image processing: Rule-based or AI models

Stable mechanical platforms

By addressing these constraints holistically, modern AOI systems deliver consistent detection, fewer false rejects, and robust performance across bottle types and production speeds, enabling safer products and more resilient manufacturing lines.