Four Tips for Setting Up Your Line Scan Vision System

Line scan cameras are well suited for inspection tasks involving fast-moving objects and endless material. Combining subsequent lines produces high-resolution images that cannot be achieved with area scan cameras. This article shows why line scan cameras are often the better choice and what special features need to be considered when setting up a line scan vision system.

Content

When do I need a line scan vision system?

How do I choose the right line scan camera?

Which lighting do I use in the line scan vision system?

What do I need to consider for resolution and triggering?

When do I need a line scan vision system?

Line scan cameras are particularly well suited for inspecting fast-moving objects or endlessly moving material. We show their typical applications and why an area scan camera is not suitable for such applications.

Application areas for line scan cameras

Inspection with a moving camera

A line scan vision system is well suited for inspecting long, static objects where the camera is moving.

Examples:

Railroad tracks

Tunnels

Applications in robotics

Inspecting moving goods

Line scan cameras are well suited for inspecting moving goods that are produced continuously.

Examples:

Endlessly produced goods (e.g. film production, battery cell production, printed products)

Piece goods, e.g. for parcel sorting

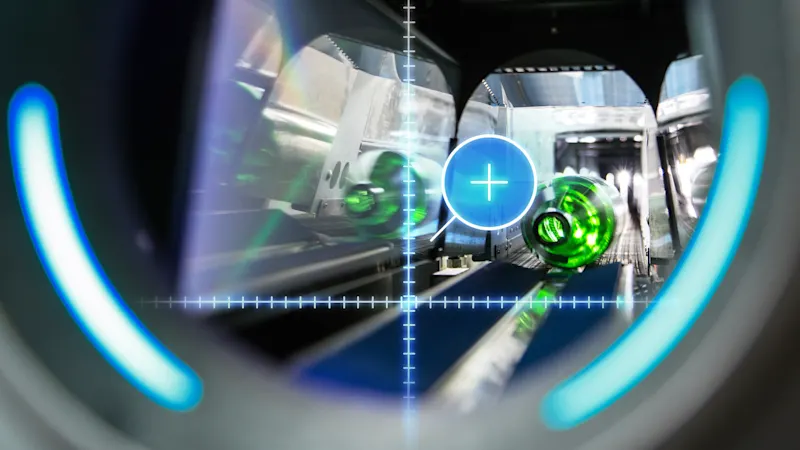

Inspecting cylindrical objects

Cylindrical objects can be displayed sharply and undistorted with a line scan camera. To do this, they are rotated under the camera.

Examples:

Barrels

Ampoules

Car tires and rail vehicle wheels

Complete the form below to read the full White Paper. All content is available online immediately after submitting the form.