360° Scanning of Parcels

Automatically recognize codes and text in any position

Codes identify shipments, materials, goods, containers, and storage locations: The automatic recognition and reading of codes and text plays a decisive role in parcel handling and intralogistics. With 6-sided scanning, parcels can be placed unsorted on conveyor belts. In contrast to laser scanners, a scanning system with image processing is more robust and multifunctional: different 1D and 2D codes as well as text recognition (OCR) can be read simultaneously.

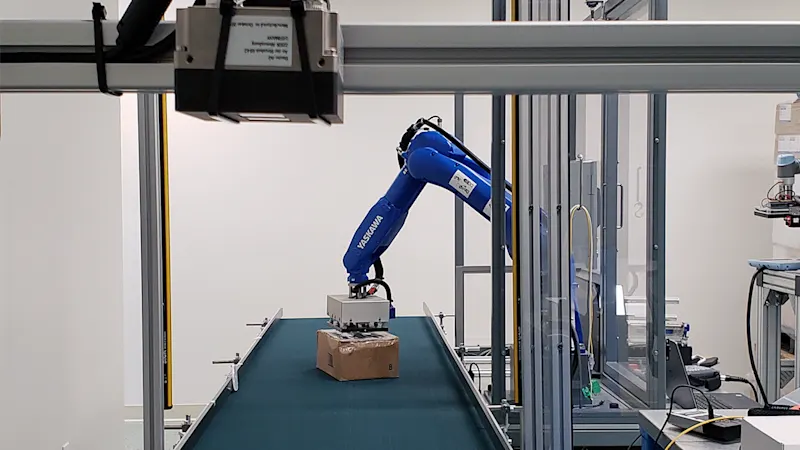

6-sided scanning fully automates parcel capture

6-sided scanning allows parcels to be placed unsorted on conveyor belts. All sides are scanned simultaneously and codes and text of any orientation are read—even if shipping labels are damaged or multiple labels are present. Sorting processes can thus be further automated and optimized, allowing efficiency and speed in the overall process to increase considerably.

Five-sided coverage and sufficient depth of field

Even if logistics processes are usually slower than electronic component production, conveyor belts still generally move at speeds of around 1.5 m/s. Conveyor belts are typically around 80 cm wide. At this width, the depth of field (the area in which an object is still sufficiently in focus despite varying distances) is technically challenging and often insufficient.

As a solution, four cameras can be arranged rectangularly above the conveyor belt. They are aligned to the center and inclined horizontally by 45°. In this way, the codes attached to the packages always pass through the focus region of the camera-lens combination.

The smallest element of a code determines the resolution

The ace 2 R camera a2A5320 in combination with the Lens C12-1224-25M offers the optimum camera-lens combination in this system setup. The resolution of more than 16 MP makes it possible to display even small elements of barcodes with widths of around 0.5 mm or 1.5 pixels. This is the width required for reliable decoding.

The interfaces best suited to this application are USB 3.0 or 5GigE, depending on the required cable length to the computing unit.

The compact line scan camera racer 2 S reads codes and writing on the underside

For complete scanning of all six sides, the contact surface (i.e. the underside of the parcel) must also be captured. Line scan cameras can capture codes line by line through narrow gaps between two conveyor belts: The extremely compact racer 2 S line scan camera (with a form factor of just 29 mm x 29 mm) can therefore be easily integrated underneath the conveyor belts.

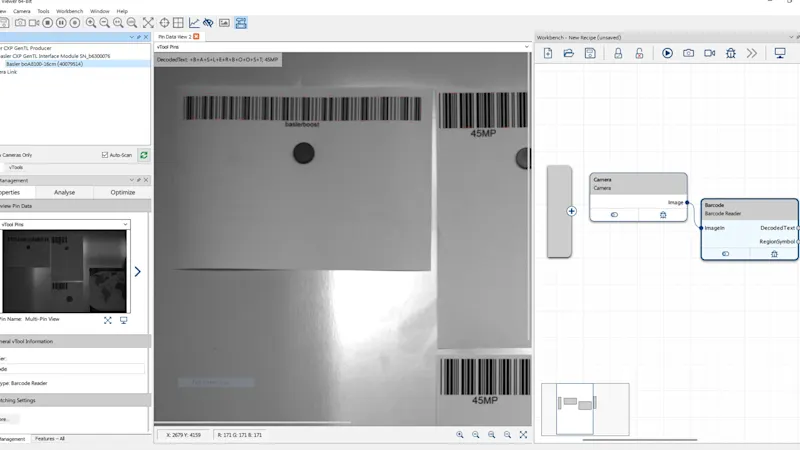

New line scan cameras with GigE and CXP-12 interfaces offer simplified configuration

The new generation of line scan cameras – Basler racer 2 S and racer 2 L – relies on the latest GigE and CoaXPress 2.0 interfaces. The interface update makes the cameras even more user-friendly:

GigE Vision line scan cameras do not transmit each recorded line, but combine several lines into a larger frame. Our Product Documentation explains in detail how to define frames for different applications and configure Basler GigE line scan cameras easily and optimally in the pylon Software Suite.

Compared to the CameraLink interface, which was previously often used at high speeds, CXP-12 simplifies image acquisition and parameterization of line scan cameras. The pylon Software Suite can now be used to make all relevant settings for cameras and frame grabbers conveniently and centrally in a single user interface . You can find out more in our Product Documentation.

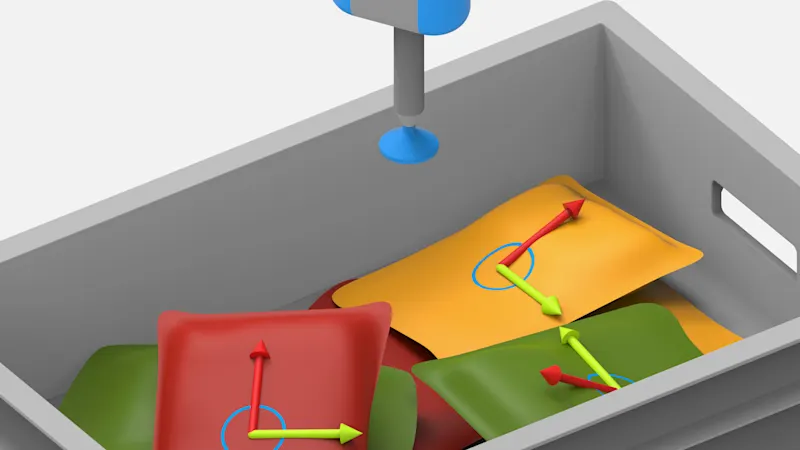

AI and rule-based algorithms read multiple code types and text simultaneously

The real advantage of machine vision becomes apparent when reading codes: in contrast to laser scanners (which can only read 1D codes, such as barcodes), camera technology in conjunction with powerful image processing software is able to read multiple code types and text.

pylon vTools read 1D and 2D codes

Barcodes and QR codes are often combined on parcels–for shipment tracking, sorting, and traceability. While 1D codes mainly contain basic data, 2D codes enable additional information to be displayed thanks to their higher information density.

Depending on the application, the Basler pylon vTool software add-ons can be flexibly combined for different code reading tasks.

AI makes OCR more robust and error-free

Thanks to AI, optical character recognition (OCR) performs better: Distorted or weakly pronounced characters are captured precisely – even if they are poorly separated from the background.

The pylon AI vTool OCR Pro delivers exact results:

for reflective, low-contrast, and uneven surfaces

on flexible packaging

with differently positioned objects

in fast-clocked applications