Basler ace 2 X visSWIR -SWIR Cameras

See what remains hidden from our eyes

The ace 2 X visSWIR cameras offer superior image quality in both visible and short-wave infrared spectrums. Compact and cost-effective, they excel in applications like penetrating complex structures or detecting hidden objects, where conventional SWIR cameras are too large or expensive.

visible + SWIR

Image acquisition in the visible and short-wave infrared spectrum up to 1.7 µmSmall size, small price

Camera with a compact housing measuring just 29 mm x 29 mm at a low priceHigh image quality

This uncooled camera delivers exceptional image quality thanks to innovative firmware featuresExtensive visSWIR accessories

Coordinated components for a complete vision system from a single source

The best of both worlds thanks to innovative firmware features

Our ace 2 X visSWIR cameras combine the high image quality of a cooled SWIR camera with the size and price of an uncooled SWIR camera.

SWIR sensors (short wavelength infrared, or SWIR) based on InGaAs technology tend to have pixel defects that become visible as white dots in the image. A longer exposure time or increased sensor temperature intensify this effect. Therefore, cameras with cooling are often used, resulting in a detrimental effect on the size and price of the SWIR cameras.

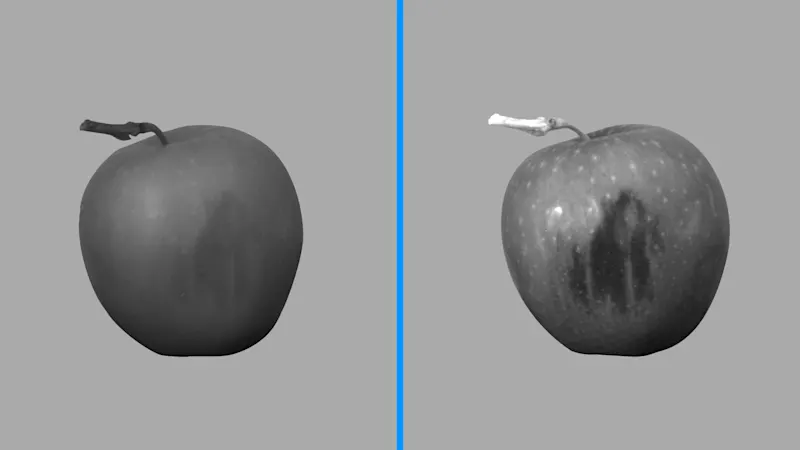

Images without pixel defects thanks to Pixel Correction Beyond

Pixel defects, common in InGaAs sensors, can negatively affect image processing. Pixel Correction Beyond, a dynamic defect pixel correction technology, is a key factor behind the exceptional image quality of our SWIR cameras.

This feature uses an algorithm we developed to dynamically detect and correct pixel defects in real-time within the camera's FPGA, ensuring that image content remains distortion-free. The image comparison highlights its impact at a sensor temperature of 35°C and an exposure time of 50 ms, demonstrating how Pixel Correction Beyond significantly minimizes pixel defects.

More about Pixel Correction BeyondHomogeneous background thanks to Line Noise Reduction

In order to achieve the same excellent image quality with the SWIR cameras with VGA or 1.3 MP resolution (IMX991 or IMX990) as with the high-resolution SWIR cameras, these models feature Line Noise Reduction.

This feature minimizes background noise, which is visible as horizontal stripes in the image, in real time and thus ensures a more homogeneous background.

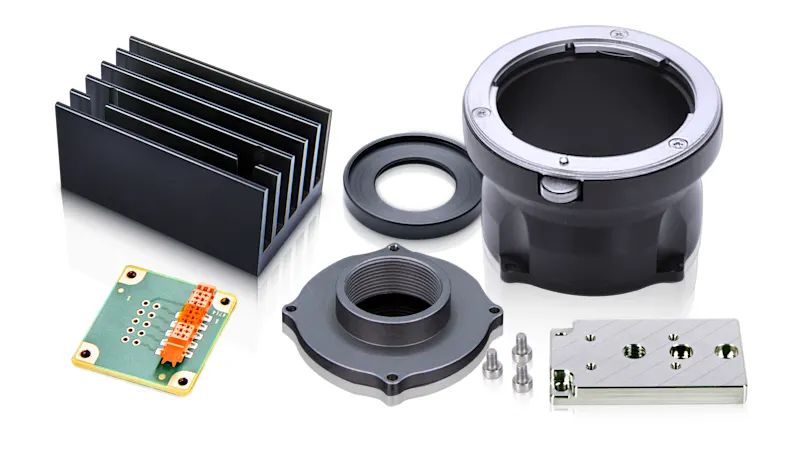

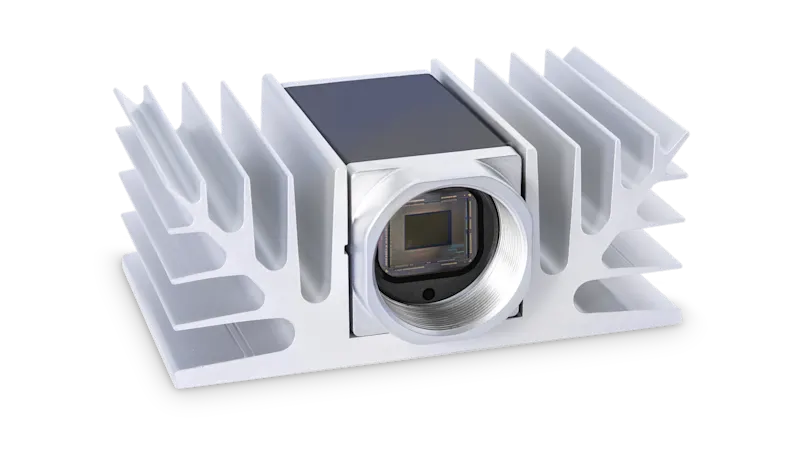

Optimal image quality—even for longer exposure times—thanks to external cooling

The image quality of InGaAs sensors decreases significantly with increasing exposure time and sensor temperature. For applications with longer exposure times of over 10 milliseconds, it can therefore make sense to reduce the sensor temperature using external cooling in order to obtain optimal image quality.

Our cooling solutions combined with our advanced image processing algorithms significantly improve the signal-to-noise ratio (SNR) and thus the image quality. This means that you get excellent images even with longer exposure times of up to 1 second.

Our external cooling systems work without fans. As a result, you retain all the advantages of an uncooled camera over a camera with integrated cooling, including: low space requirement, an attractive price, and lower power consumption. In addition, they ensure stable image acquisition without vibrations and are ideal for use in cleanrooms as there is no air turbulence.

Passive cooling fins

Easy to use, especially suitable for initial evaluation

No moving parts

Stabilizes the sensor temperature to < 45 °C (depending on air circulation and sensor used)

Active compressed air cooler

Excellent cooling performance with a small footprint

No moving parts

Stabilizes the sensor temperature to < 33 °C (depending on the compressed air system and the sensor used)

ace 2 X visSWIR camera models

Find the right camera for your application or use our Vision System Configurator to configure your system.

Capabilities of the ace 2 X visSWIR cameras

The ace 2 X visSWIR cameras detect light in both the visible and short-wave infrared range (SWIR). In the SWIR range with wavelengths from 0.9 µm to 1.7 µm, many materials have different optical properties. This opens up new application fields.

Look below the surface

Due to the longer wavelength, short-wave infrared light penetrates some materials, causing them to appear transparent. This allows SWIR cameras to see what lies beneath the surface. For example, bruises on fruit and vegetables can be detected, fill levels can be checked in otherwise opaque containers, and semiconductors can be inspected for defects.

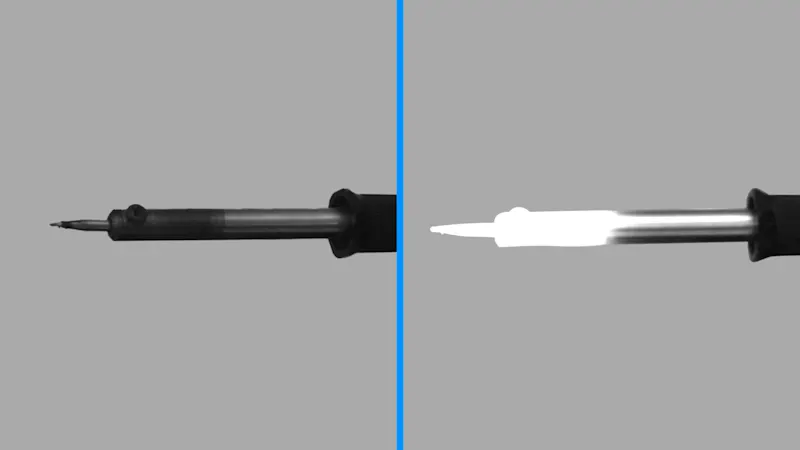

Temperature detection

Hot surfaces (from approx. 140°C) emit light in the short-wave infrared range, which is why SWIR cameras are used to measure or estimate the temperature of objects. The intensity in the image is directly related to the temperature. This property can then be used to monitor thermal processes, such as the inspection of welding seams.

Typical application fields in the SWIR spectral range

The variety of applications for vision systems in the SWIR spectral range extends from semiconductor inspection and recycling to quality inspection and sorting of food products.

Interested in a solution with visSWIR technology?

Allow us to check and test your application.

Contact usMore products for your complete visSWIR system

Further information on the Basler ace 2 X visSWIR

No results were found for your search.

Please try one of the options below:

Try a different search term.

Try a more general search, e.g. start with fewer search terms and refine your search as you go.

Check that no filters are set and remove them if necessary.