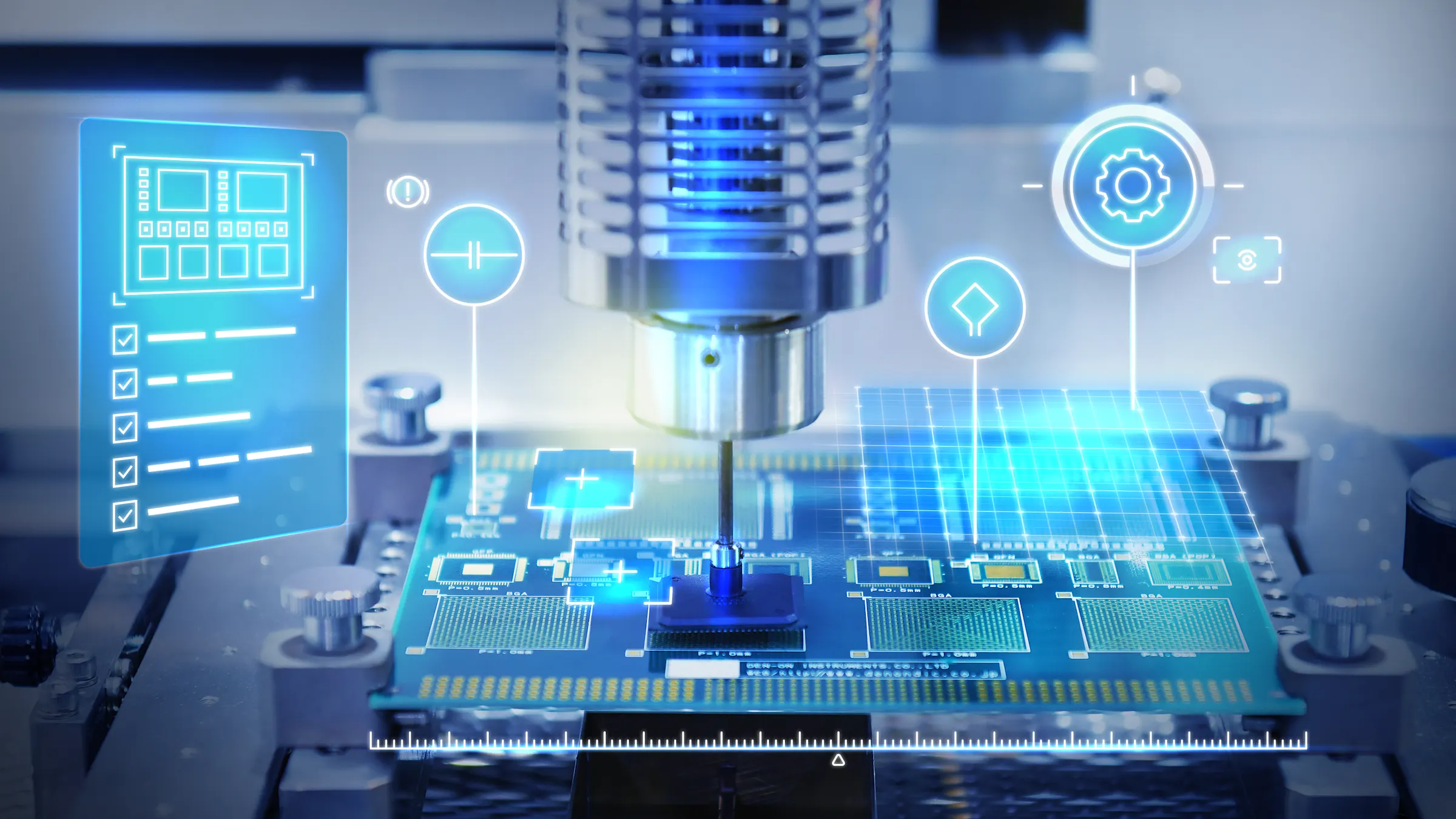

Electronics Inspection

Consistent quality. For every board, panel, and device.

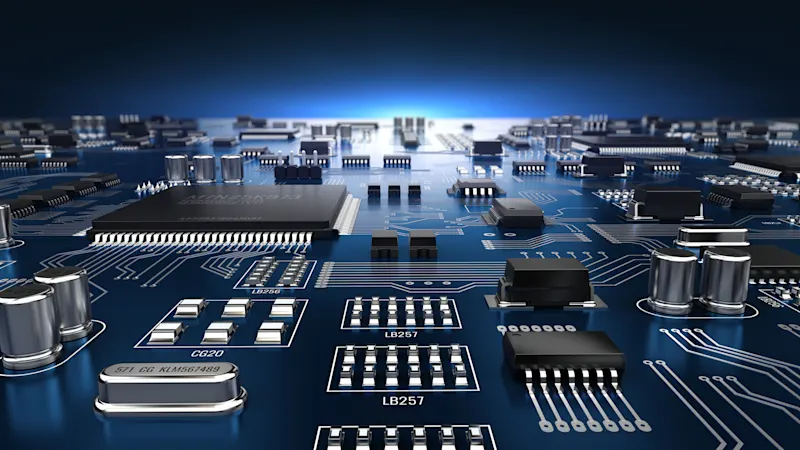

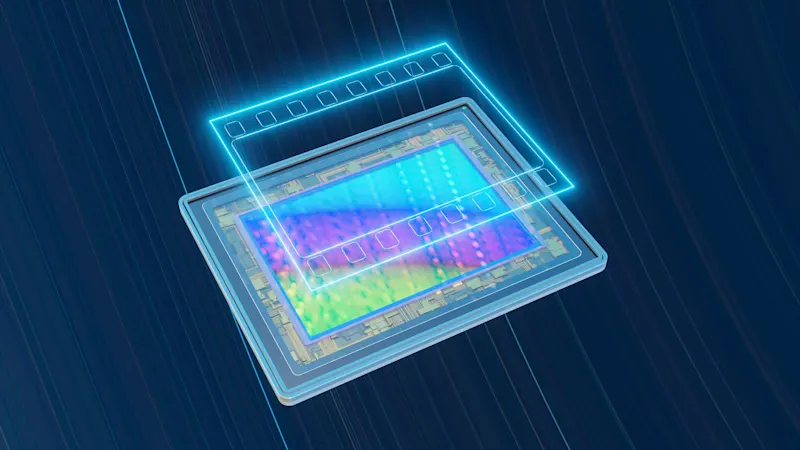

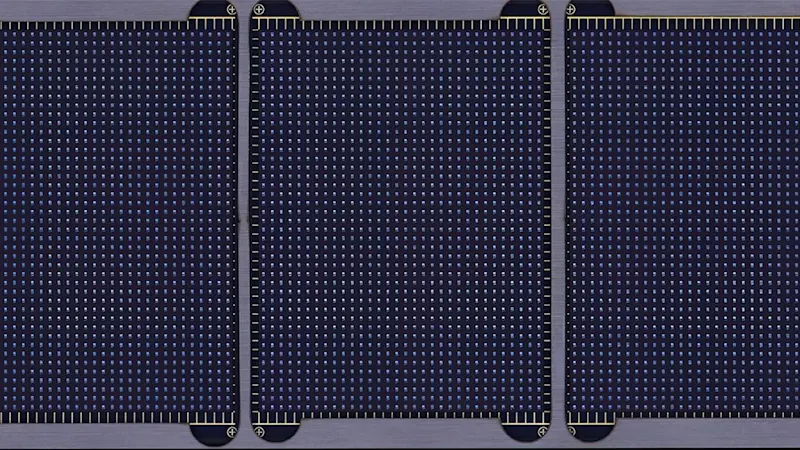

From PCB manufacturing and display panel assembly to building complex electronic components, precision and speed are critical in electronics manufacturing. As demands for miniaturization, higher performance, and tighter tolerances continues to grow, Basler’s vision solutions empower industry partners to develop reliable, high-quality inspection systems tailored to the evolving needs of the electronics industry.

High performance & speed

Innovative, high-performance camera technology for state-of-the-art production methodsDurable & reliable

With the lowest failure rate in the industry, our camera systems stand for reliability in 24/7 operationSimple integration

All of our components are compatible and easy to connect to target systems using pylon softwareAvailability & reliable delivery

Stable supply chains ensure long-term availability of our products and prevent production downtime

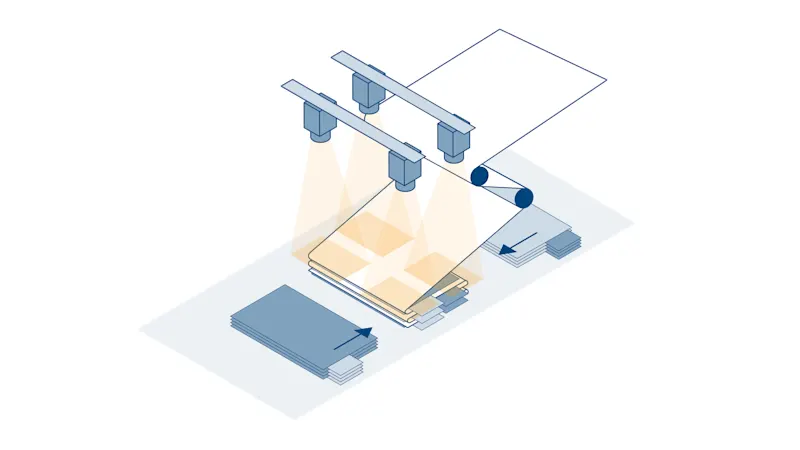

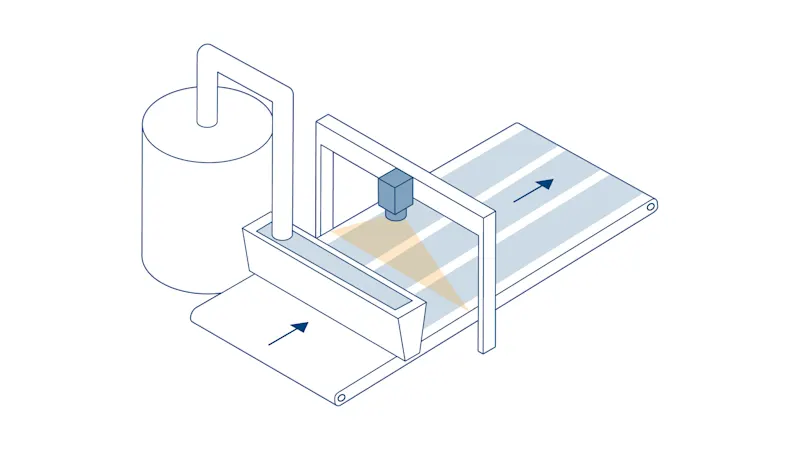

Typical fields of application in electronics

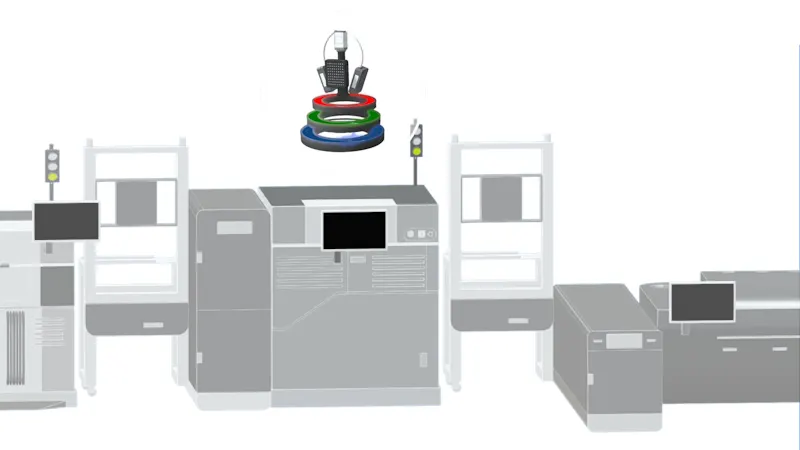

Electronics defect inspection demands speed, precision, and clarity. Basler meets these demands with real-time processing, superior image quality, advanced optics, and AI-compatible software—all seamlessly integrated for fast, reliable inspections.

Vision know-how and application examples in the electronics industry

From vision system design to specialized camera features to addressing industry-specific challenges, Basler enables inspection precision at every level. Our solutions support a wide range of inspection applications across the electronics sector.

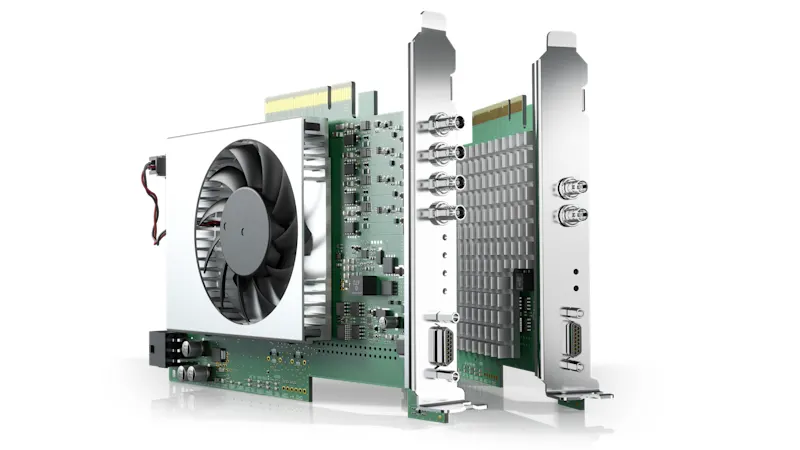

Most popular products

For efficient and reliable machine vision applications in this industry, the following Basler products are often the best choice: