Precisely Positioned: Quality Assurance for Stacking

During the assembly of pouch battery cells, the stacking process requires precise layering of individual electrode sheets and a separator. Machine vision provides precise positioning in the µm range, ensuring the accurate stacking that is critical for the quality and lifetime of the resulting battery cell.

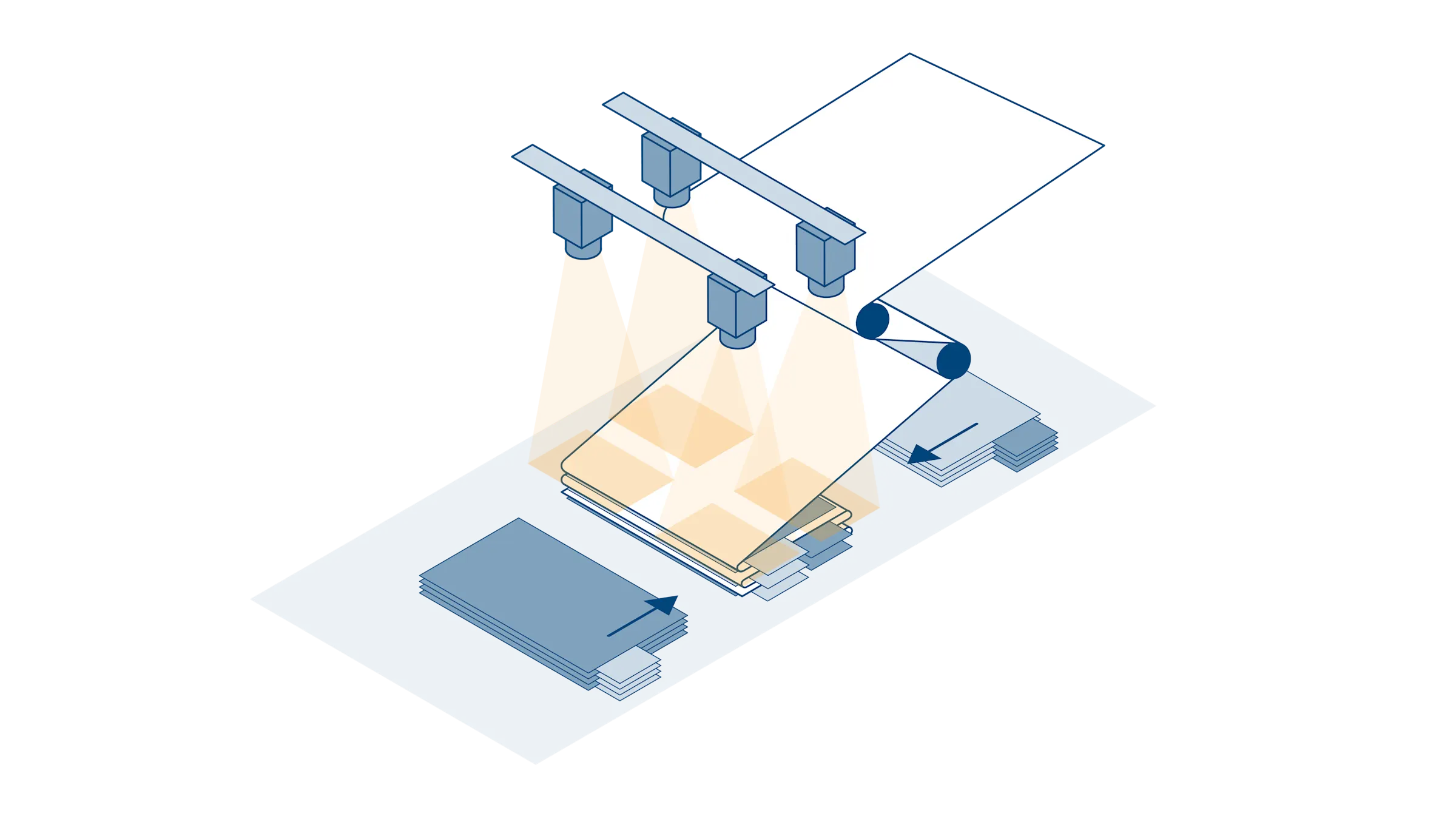

Z-folding in pouch cell assembly

Pouch batteries are manufactured by stacking electrode-coated cell sheets. In the Z-folding process, the pre-cut anode and cathode sheets are inserted into the separator foil from both sides. The separator foil is supplied as a rolled-up, continuous web material. This Z-shaped arrangement of the electrode sheets and separator foil gives the process its name.

The process is repeated continuously and up to 120 layers can be created. Once complete, the battery manufacturer seals the edges of the foil. Afterward, the cell stack is wrapped with foil, the foil is cut off, and the remainder is secured with tape.

Micron-level accuracy in positioning electrode plates

Vacuum gripper systems pick up individual anode and cathode sheets and alternately place them on the separator. Precise positioning of the electrode sheets and the separator is critical to the quality of this process step.

The edge alignment must be as accurate as possible, with tolerances in the µm range: deviations of less than 200 µm are acceptable. High speeds add to the challenge of this process step: the electrode sheets are picked up and placed on the cell stack in less than 1 second!

Machine vision provides the necessary quality control

The production of battery cells is subject to strict regulations to eliminate potential hazards that could result from errors in individual production steps. Machine vision systems, consisting of high-performance cameras and software, ensure that finished parts are produced correctly.

Four cameras working in sync

In the inspection process, four cameras check the correct positioning of the electrode sheets at each corner. The CoaXPress 2.0 standard ensures precise triggering in multi-camera systems and real-time data transmission. The captured image data can be analyzed using the pylon vTools software to determine the exact stacking of the electrode sheets.

High performance in a small form factor: ace 2 V camera

Space-saving 29 mm x 29 mm footprint for easy integration of the ace 2 V camera into existing and new stacking systems

Brilliant, high-resolution images thanks to Sony Pregius S sensors and Basler firmware feature sets

CXP-12 interface enables bandwidths up to 12.5 Gbps

Single-cable solution via Power over CoaXPress for easy cabling and integration

Robust and reliable deviation measurements with pylon vTools Software

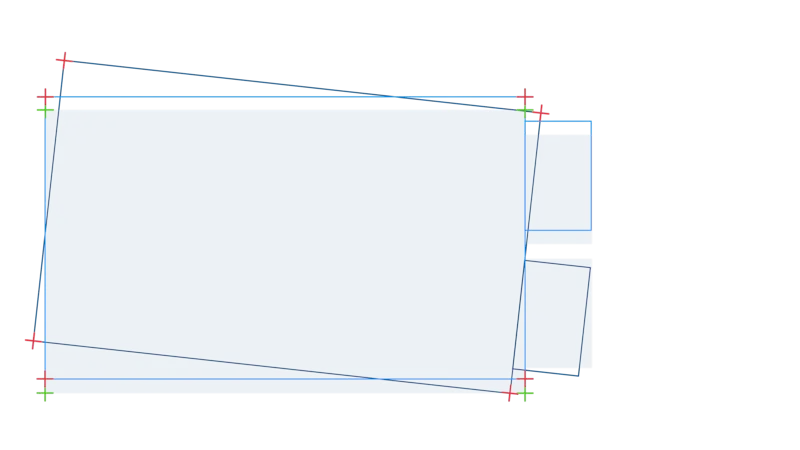

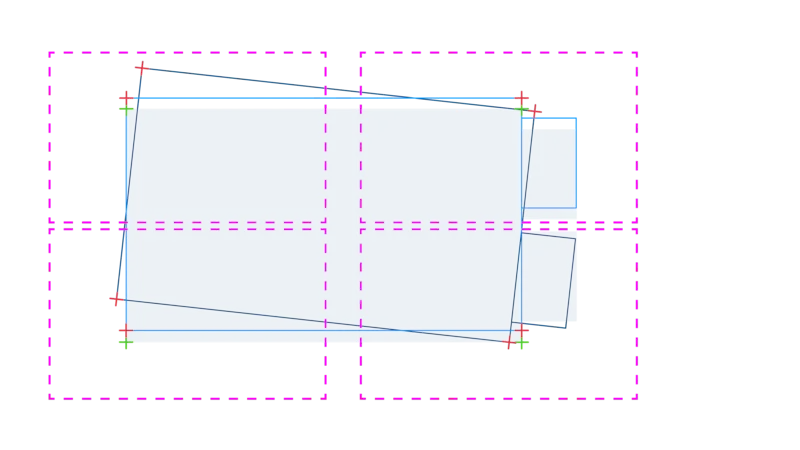

pylon vTools software analyzes the captured images. For example, a multi-step recipe can be created as follows:

vTool Calibration & Rectification: Ensure that the measured distances are output in calibrated metrics. Compensate for radial and perspective distortions caused by camera settings.

vTool Measurements: A model image can be used to define a measurement rectangle. During the process step, possible deviations in other acquired images of stacked anode and cathode sheets are output:

in coordinates, if there is a rotation

or in metrics for distances to target edges.

Image pre-processing to manage large image data

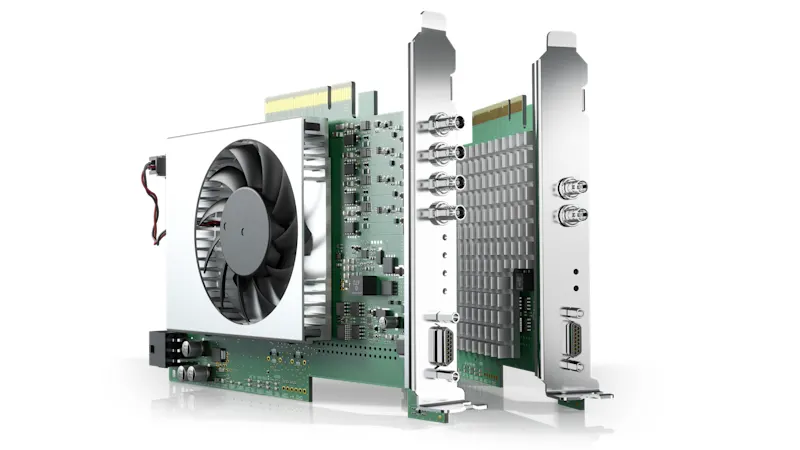

Lean data management: Thanks to the CXP-12 interface, the system can be extended with frame grabber-based image pre-processing. This allows large amounts of image data to be analyzed in a targeted manner, reducing the load on the host computer's CPU.

Our VisualApplets Software is the perfect complement to the latest generation of programmable imaFlex frame grabbers.

Products for this solution

Looking to implement a comparable solution? These products will help you.