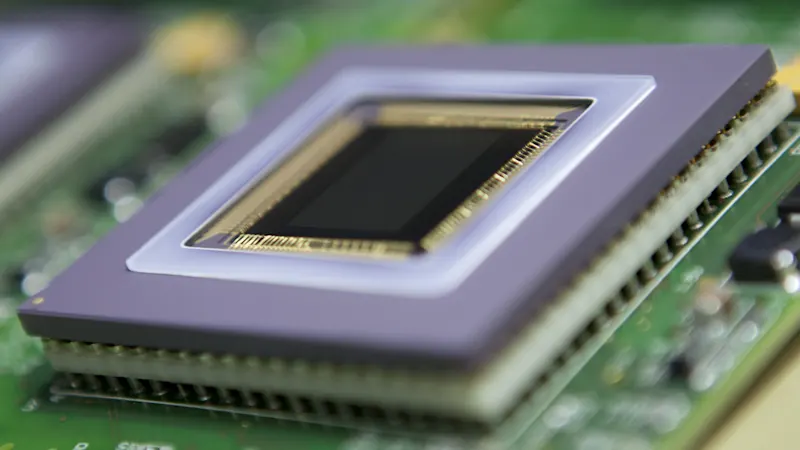

Comparing Sony's IMX CMOS Sensor Series

The models in Sony's IMX series are among the most frequently used sensors in industrial cameras. But which series is the right one for your application? Learn more about the key differences between the various IMX model series from Sony, also known as Pregius, STARVIS, and Pregius S.

Content

The first IMX sensors

Just a few years ago, CCD technology made up by far the largest share of camera sensors for industrial image processing. At that time, CMOS sensors were considered a promising but not yet mature technology in which even experts did not see any immediate competition to the established CCD sensors.

This changed abruptly when Sony, as one of the most important international sensor manufacturers, announced the discontinuation of its CCD production at the beginning of 2015. This heralded the end of the CCD era in industrial image processing and in many other areas. About two years earlier, the company had introduced the first of (currently) four generations of a new CMOS sensor family called IMX, which caused a particular stir with its significantly larger dynamic range. These sensors, which are still available, enable short exposure times, have the selection of trigger and readout options required in image processing, and allow images to be captured in outstanding quality that exceeds that of competing sensors in the same price segment.

What makes the IMX sensors so special?

Exmor technology for high image quality

One of the contributing factors in the high image quality of IMX sensors is a special technology from Sony called Exmor, in which the noise-reduced analog signal recorded by the sensor is converted into a digital signal directly when the pixels are read out. This approach distinguishes IMX sensors from their competition and not only improves noise performance, but also enables higher frame rates.

Global shutter for shots without distortion

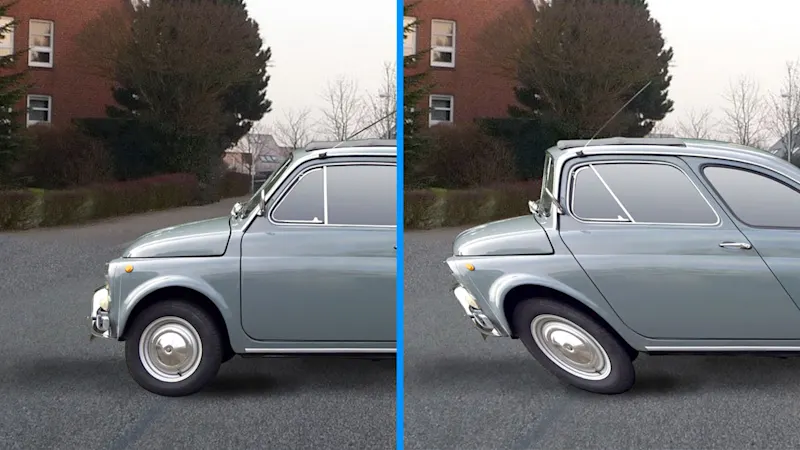

Another particularly important feature of a sensor is its shutter. Implemented in the sensor electronics, it corresponds to the functionality of an aperture in a conventional camera. In industrial image processing, two different concepts exist here: rolling shutters and global shutters. In sensors with rolling shutters, the lines of a sensor are exposed and read out one after the other. In applications with moving objects, this procedure leads to a time-delayed exposure of the sensor lines and (depending on the inspection situation) can cause undesirable distortions in the captured images.

Sensors with global shutter work differently: they read out all exposed pixels at the same time, ensuring that images of moving objects can be captured without distortion. An example of this is capturing images of moving vehicles or objects in traffic applications.

Smaller ROI for higher speeds

In addition, Sony developers integrated functions into their first IMX generation that brought large advantages for industrial image processing. These include the ability to define smaller regions of interest (ROIs). Limiting the sensor readout area increases the speed of image acquisition and reduces the size of image data for data transmission. This feature is especially beneficial when only certain small areas need to be viewed for the inspection of objects.

Pregius - the first generation of IMX sensors

IMX174 and IMX249 IMX174 and IMX249 are the names of the sensors in the first IMX generation, also known as Pregius. These global shutter sensors contain square pixels with an edge length of 5.68 µm and a resolution of 1920 x 1200 pixels. They differ in speed: IMX249 allows an image acquisition speed of 41 frames per second, while the high-speed IMX174 variant achieves an impressive 166 frames per second. For applications where a resolution of 2.3 megapixels is sufficient to solve the task at hand, cameras based on IMX174 and IMX249 sensors are often still the perfect choice due to their high saturation capacity, high signal-to-noise ratio, and impressive dynamic range.

Second IMX generation with reduced pixels

In the second generation second IMX sensor generation, Sony reduced the pixel size to 3.45 µm x 3.45 µm and introduced models with resolutions of 3 MP (IMX252 and IMX265), 5 MP (IMX250 and IMX264), 9 MP (IMX255 and IMX267), and 12 MP (IMX253 and IMX304) in late 2016. These sensors also offer users the benefits of a global shutter and use Exmor technology for outstanding image quality. In terms of speed, the standard second-generation models (IMX265, IMX264, IMX267, and IMX304) range from 23 to 56 frames per second, while the high-speed versions enable the capture of 68 to 216 frames per second.

Compared to the first IMX sensors, the second generation shows significant differences in saturation capacity. While clearly below the values of its predecessors, it is still in the range of CMOS sensors from other manufacturers. However, this characteristic is outweighed by the fact that Sony was able to almost triple the achievable resolution with a comparable sensor format.

Comparison of the 1st and 2nd generation IMX sensors

Sensor | IMX174 & IMX249 | IMX252 & IMX256 | IMX250 & IMX264 | IMX255 & IMX267 | IMX253 & IMX304 |

|---|---|---|---|---|---|

Resolution [MP] | 2.3 | 3 | 5 | 9 | 12 |

Resolution [pixel * pixel] | 1920*1200 | 2048*1536 | 2448*2048 | 4112*2176 | 4112*3008 |

Sensor format ["] | 1/1.2 | 1/1.8 | 2/3 | 1 | 1.1 |

Pixel size [µm] | 5.68 | 3.45 | 3.45 | 3.45 | 3.45 |

max fps @Basler | 164 | 120 | 75 | 40 | 30 |

The range of possible resolutions increased significantly with the 2nd generation of IMX sensors.

STARVIS sensors with backside-illuminated technology

With the STARVIS family, Sony has been offering a powerful sensor technology for quite some time. It initially existed only in different color variants and was used primarily in surveillance applications. After the introduction of monochrome STARVIS models, these sensors became increasingly interesting for factory automation applications. This sensor family from Sony was developed in parallel with the Pregius line and was initially only available with rolling shutter, but later also offered global shutter. STARVIS sensors are also marked with the abbreviation IMX and work with square pixels between 1.85 µm and 3.76 µm edge length.

STARVIS vs Pregius sensors

The most important distinguishing features between STARVIS and the first and second Pregius generations are the rolling shutter and the backside-illuminated technology of the STARVIS sensors.

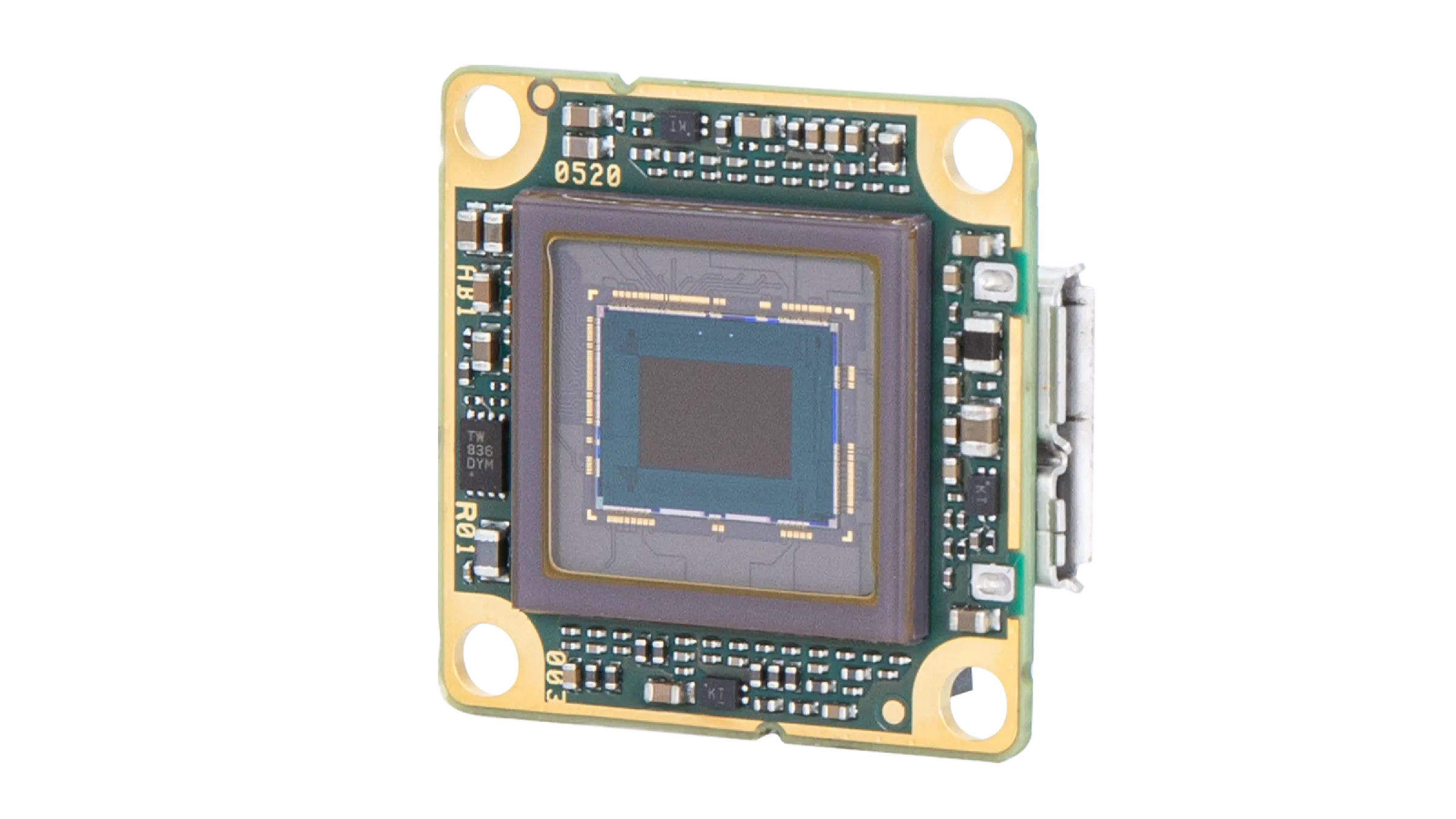

Frontside-illuminated (FSI) compared to backside-illuminated (IMX) sensor

This sensor design, also known as BSI, is a sophisticated development by Sony that elegantly solves a problem. STARVIS sensors work with very small pixels up to 1.85 µm edge length. With such small pixel sizes, there is an unfavorable ratio between the sensor areas available for light-receiving pixels and the required electronic components such as amplifiers or A/D converters. If the non-light-sensitive portions increase, the quantum efficiency of a sensor decreases.

Sony avoids this situation by placing the pure amplifier and evaluation electronics on the back of the sensor rather than the front, as is the case with conventional, so-called frontside-illuminated sensors (FSI). Only the light-sensitive parts of the sensor are placed on the front. This trick allows almost the entire pixel area to be used for the photoelectric response and reduces the reflection of light from the electronic components. In addition, the light-sensitive plane of a BSI sensor is higher than in the conventional FSI design, which also contributes to improved imaging performance.

Sensitivity threshold

The effects of this can be seen by comparing the absolute sensitivity threshold, which is defined in the EMVA1288 standard. This indicates how much light, i.e. photons, the sensors need on average to generate a signal that stands out sufficiently from the noise. This value is 10 for first-generation Pregius sensors, while second-generation Pregius models achieve a value of 3 and STARVIS sensors achieve a value of 4.

STARVIS | Pregius 1st gen | Pregius 2nd gen | |

|---|---|---|---|

Absolute sensitivity threshold | 4 | 10 | 3 |

Pregius S, the current 4th generation

In 2020, Sony introduced the Pregius S, currently the most advanced generation of sensors with a pixel size of 2.74 µm x 2.74 µm and resolutions from 5.1 to 24.5 megapixels. The Standard models IMX540, IMX541, IMX542, IMX545, IMX546 and IMX547 cover image capture speeds from 35 to 122 frames per second or up to 870 megapixels per second, which High-speed variants IMX530, IMX531, IMX532, IMX535, IMX536 and IMX537 even achieve 106 to 259 frames per second or up to 2600 megapixels per second, thus enabling the inspection of very fast-moving objects.

Pregius S sensors combine the benefits of BSI technology developed for the STARVIS family with the global shutter approach of the first two Pregius series and continue to leverage the advantages of Exmor noise reduction.

Which IMX sensor is the right one?

The application

Deciding which CMOS sensor is best suited for an application depends on the task at hand. One of the decisive criteria is the trigger speed of the cameras used and their sensors: If images of fast-moving objects are desired, triggering must be as fast and precise as possible. Here, Pregius sensors have better values than STARVIS series sensors: The time between triggering and reading out an image is only about 20 µs for Pregius sensors, while STARVIS sensors may require 450 µs or more. Cameras with Pregius sensors are therefore the better choice in applications where precise execution of the trigger is crucial for image quality. Examples from industry include inspecting very fast-moving objects, such as bottles or printed circuit boards, as well as motion analysis in sports. 3D applications or applications using multi-camera systems also benefit from the high trigger speed and accuracy of Pregius-based cameras.

IMX sensors as a replacement for CCD

Users are often looking for an adequate CMOS replacement for cameras that have comparable characteristics to CCD technology. For reasons of economy, it makes sense to select cameras with a CMOS sensor that requires the least possible adaptation of the existing lighting and optics. The formats of the Pregius sensors resemble those of earlier CCD cameras to a greater extent than the STARVIS series and are therefore more suitable for applications in which this argument is particularly important. For example, the 5 MP IMX264 and IMX250 variants of the Pregius series can function excellently as replacements for the widely used ICX625 CCD sensor. Cameras equipped with the ICX824 CCD sensor can be replaced with little effort by models with the 8.9 MP Pregius versions IMX267 and IMX255, without having to make major adjustments to the optical setup of the system.

Cost benefits

STARVIS sensors, on the other hand, offer a clear cost advantage over the Pregius series. If the objects to be inspected do not have to be recorded in motion, the rolling shutter of STARVIS-based cameras is of little consequence. Due to their very small pixel size, these sensors also allow higher resolutions with a smaller sensor, but this must be considered when selecting optics.

Trends in the development of the IMX series

New functions

Sensor developments in recent years show a trend toward increasingly diverse functions in new models. Sony, for example, introduced a multi-exposure trigger with the second Pregius generation, in which a single trigger impulse triggers the rapid capture of multiple images, allowing an object to be captured with different image brightnesses. In this way, the optimum image can be selected for subsequent image evaluation. This function is also available to users of the third and fourth generations. This trend also applies to two innovations in the third generation, which introduced so-called self-triggers and dual-triggers in the high-speed sensors. With a self-trigger, two different image areas (regions of interest, ROI) are defined and an image is captured of one of the two areas as soon as a change is detected in the other image area. The dual-trigger function in turn enables the definition of two different values for exposure time and gain, which can be controlled independently of each other. Self-trigger and dual-trigger are included in all fourth-generation sensors.

These examples show that the functions of previous sensor generations are usually carried over to the next development stage, giving users even more options.

Smaller sensors with high resolution

Another important trend in sensor development is toward ever-smaller sensors with high resolution. This is made possible by ever-smaller pixel sizes, which are enabled by advances in production processes. This miniaturization of the sensors results in the possibility of further reducing camera sizes as well. In addition, in certain cases, the number of cameras used can be reduced due to the higher resolutions. The use of cost-optimized camera systems also becomes possible as a result. With Pregius sensors, cost-intensive 1" lenses are often required, which can be replaced by less expensive but equally powerful lenses with the smaller sensor sizes of the Pregius S series. This makes the use of cameras with Pregius S sensors very popular.

Summary

The technical features of the first four IMX generations—Pregius, STARVIS, and Pregius S—offer developers and users in numerous application fields (such as industrial image processing) extensive options in terms of available resolutions, speeds, and functions. Due to constant developments, it can be assumed that the next generation of sensors will offer even more extensive technical possibilities.