Industrial Cameras

The right camera for your application

Discover our wide range of robust, industrial cameras with state-of-the-art sensors and interfaces. From area scan and line scan cameras to 3D and embedded vision - find the perfect camera for your industrial image processing tasks. Expand your system with our compatible hardware and software.

Basler industrial camera

See our large portfolio for yourself: Whether you need mono or color cameras, with CMOS sensors from manufacturers such as e2V, AMS, Sony, or onsemi, with USB 3.0, GigE, 5GigE, or CXP-12 interfaces, as well as a wide range of resolutions and frame rates - this selection will include the right industrial camera for your application.

Machine vision cameras

What does "industrial camera" mean?

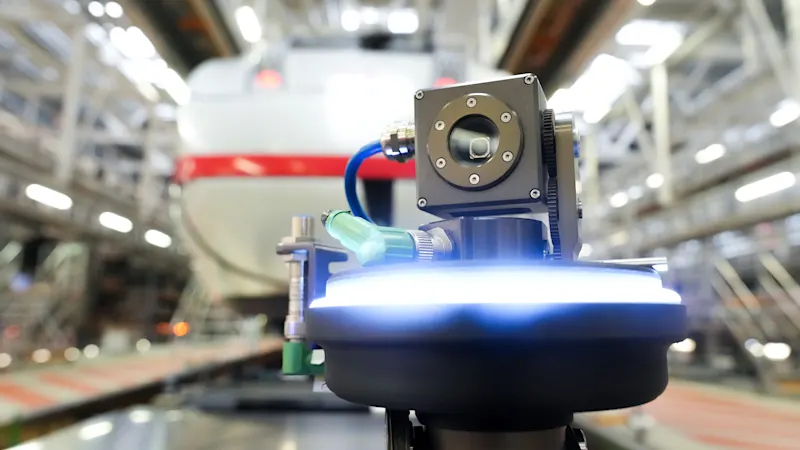

Industrial cameras can be found in many application areas today: They are used for production monitoring, for example, or they fulfill complicated measurement tasks. Industrial image processing is primarily used for quality control. Digital industrial cameras are generally more robust than conventional digital cameras because they are also exposed to other external influences, for example in applications with high ambient temperatures.

There are also other crucial differences: The image quality of an industrial camera is often higher than that of a "normal" camera, since much more detailed images must be captured, especially for certain measurement tasks. The familiar elements of a digital camera, such as a viewfinder, a shutter release, or an automatic flash, are not found in industrial cameras. These cameras are connected to a computer via an interface. The camera is then triggered via an I/O cable (I/O stands for input/output) and the signal to take a picture is sent via software installed on the PC.

How does an industrial digital camera work?

In principle, industrial cameras work like conventional digital cameras, but have additional functions and features that make them ideal for use in harsh industrial environments and for demanding applications.

Learn more about the individual components and applications in our video:

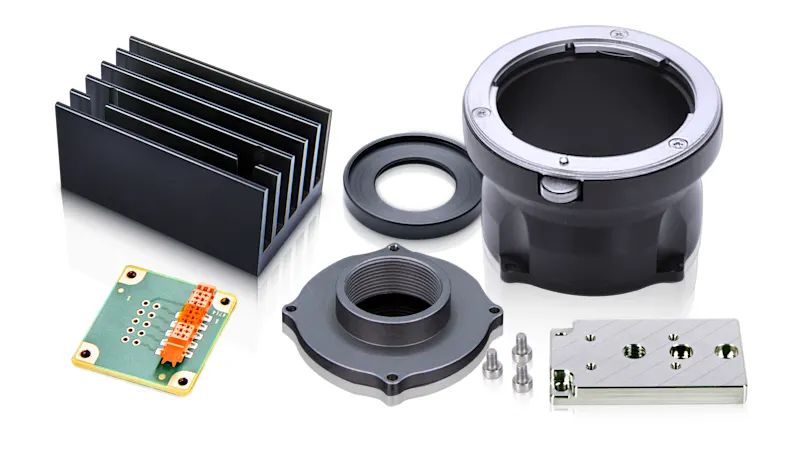

Basler industrial cameras and accessories

Our aim is to provide you with a complete system that works reliably and simply in your application. Together with the right industrial camera, our components create a perfectly coordinated vision system.

The free Basler pylon Software Suite provides software specially tailored to these industrial cameras. The pylon vTools also allow you to easily integrate image processing functions into your application.

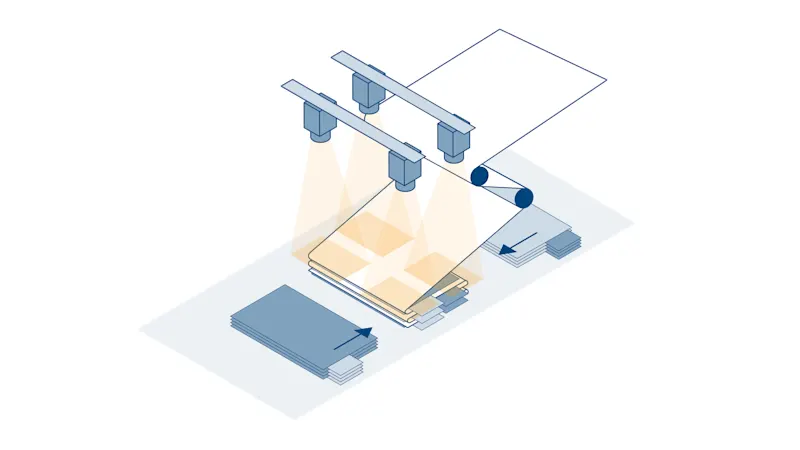

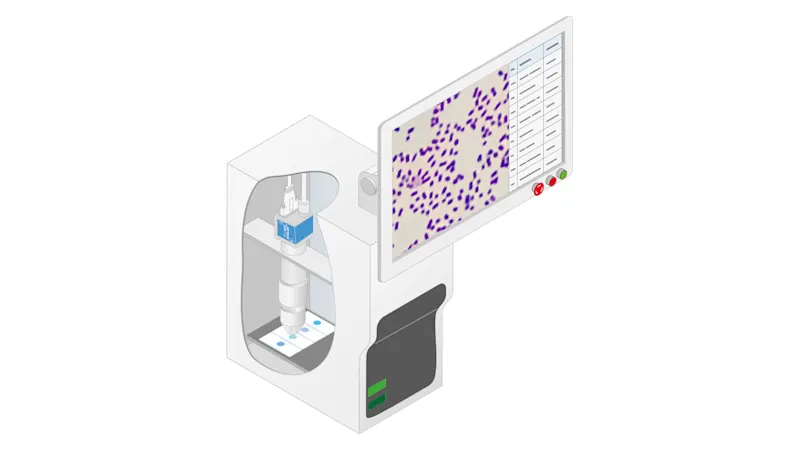

Industrial camera applications

An industrial camera can be used in a wide variety of applications. Line scan camerasare often used to inspect continuous webs, for example for print image inspection. Area scan camerascan be found in a variety of factory automation applications where they identify, sort, or inspect parts. Basler industrial cameras are used in intelligent traffic systems, retail, and microscopy applications, among others.

Basler sets standards

To ensure that Basler cameras run smoothly in your application, we not only adhere to industry-wide standards, we are also involved in defining these standards. Basler is an active member of various standardization committees such asGigE Vision,USB3 VisionandEMVA1288.

This also includesGenICam: We are one of the companies that played a key role in developing the requirements for this standard. GenICam stands for "Generic Interface for Cameras" and is a generic programming interface for industrial cameras.

Another argument in favor of Basler cameras: Basler stands for quality. We put each of our cameras through its paces and subject them to precise calibration and comprehensive mechanical, electrical, and optical tests before they leave one of our two production facilities. The leanest possible production is important to us. Thanks to lean processes, we can reduce effort, errors, and costs, producing only the high-quality cameras. We pass these benefits on to you, offering our customers our excellent price/performance ratio.