E-Check of ICE Trains

Automated inspection with mobile robot, 32 ace 2 cameras, and AI

- Customer

- Deutsche Bahn AG

- Location

- Cologne, Germany

- Date

- November 2023

Deutsche Bahn relies on imaging for maintenance tasks: with E-Check, the company can prepare for increasing passenger numbers on long-distance services.

Growing number of trains and increasing shortage of skilled workers

The Deutsche Bahn (DB), Germany's national railway company, train fleet is growing. Every month, DB puts three new ICE trains into operation. This will increase the need for maintenance, which can only be met by investing in automated systems in addition to the structural and personnel investments.

The E-Check process was launched to develop semi-automated inspection and maintenance systems for various ICE series (ICE is the abbreviation for InterCityExpress and is what Germany's long-distance trains are called). The first ICE plant to be equipped with the new technology is Cologne-Nippes. Berlin, Dortmund, Hamburg, and Munich will follow by 2025. E-Check helps by:

enabling more active trains,

facilitating maintenance planning,

and reducing personnel bottlenecks in maintenance.

Challenging conditions for camera technology and AI

Trains are complex systems with various functional units. Checking them for possible defects or maintenance requirements is a demanding task. Many challenges arise for image processing technology, including:

Large amounts of data from 32 synchronized cameras,

difficult lighting conditions,

strong environmental fluctuations, and

needing to constantly maintain the correct focus.

In addition to high-performance hardware, this task requires a complex AI software pipeline that must be validated and certified at great expense. After all, AI must be at least as reliable as a human inspection for safety-related tasks. The aim of the E-Check is therefore a hybrid inspection system: humans remain integrated in the maintenance process while AI takes on tasks to increase their efficiency.

Image processing systems are a crucial part of the E-Check

For the E-Check project, Gestalt Robotics (a software & sensor technology company) and Strama-MPS (a mechanical engineering company providing integration) formed a consortium with Götting (providing AGV hardware). Gestalt Robotics is developing the construction-specific AI models for external inspection with infraView.

The E-check consists of a camera arch that captures the entire slowly rolling train, an optional mobile underfloor unit, and mobile E-Check cobots that supply the ICE with fresh water and pump out the waste water.

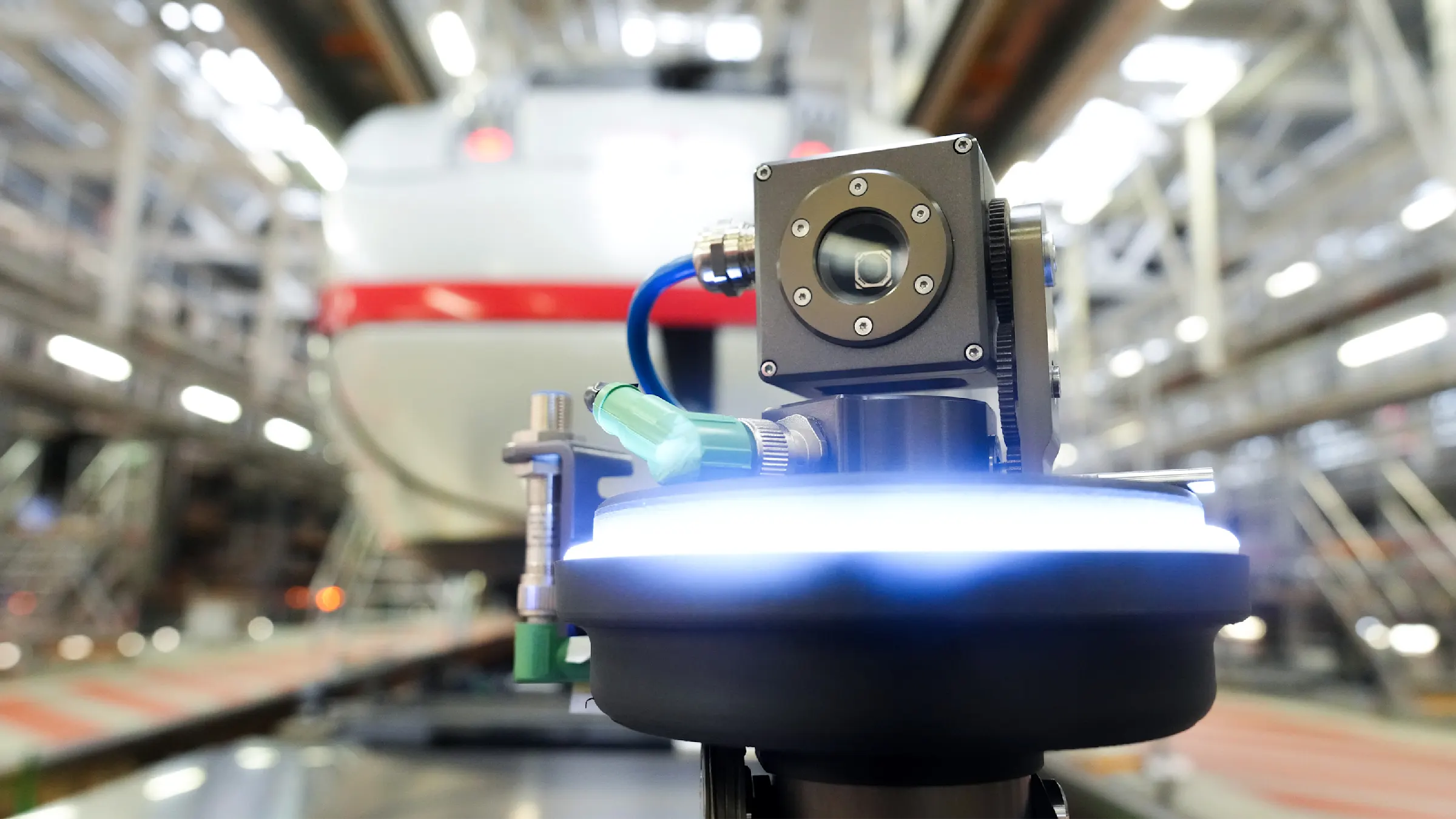

Trains entering the maintenance hall pass through the camera arch, which is equipped with 32 Basler ace 2 cameras a2A5328-4gcPRO. These record two high-resolution images per second. Mobile E-Check cobots are then used in the maintenance hall. Each cobot is equipped with two robotic arms and one Basler ace 2 camera a2A5328-4gcPRO per arm. They take care of areas that cannot be captured by static cameras.

The data collected by the cameras is processed using the "AutomateOS" middleware from Gestalt Robotics and made available for subsequent steps. A sophisticated AI system then detects and classifies any anomalies and defects. Examples include the detection of not correctly placed or missing screws, material wear and tear, or damage caused by stone chips.

Employees are also able to monitor the AI system and make corrections to sustainably and continuously improve it. On the software side, a process planner orchestrates the system and all process data is stored transparently and securely in a database.

The mobile robots not only provide support in recognizing maintenance needs, they also perform the task of emptying and filling the train's water tanks. This is done independently by a mobile cobot with two arms.

Basler is our partner of choice for outstanding camera and image processing systems. They are characterized by high-quality hardware, comprehensive service, and they support us in the implementation of future-proof, AI-capable, complex automation systems.

Basler was the first choice of our engineers and purchasing department.

Technical features of the vision system

Edge computing, due to the large data volume without a cloud connection in the on-site system

Basler pylon Software Suite as a valuable tool for pre-configuring the cameras and determining the focus

Facilitating complex inspection tasks through visual representation

Precise detection of the tension envelope due to high resolution

High-performance overall system thanks to GigE data transmission

Products for this solution

Looking to implement a comparable solution? These products will help you.

Further information

The video from Gestalt Robotics shows the development status of the E-Check preliminary project and the representation of possible defects and anomalies.