Basler CXP-12 Components in the Automotive Industry

What is the quality inspection of automotive paint with vision systems all about?

Eines Vision Systems has become one of the most crucial partners of automotive manufacturers worldwide, developing complex systems and software solutions for measurement, defect detection and image processing.

One vision system manufactured by Eines Vision Systems is the Esφi, a system for inspecting the paint quality of vehicles. The Esφi is a color scanner and the world's first system that can scan in a production line with a short cycle time. As a result, the system contributes to high productivity and efficiency in the manufacturing process without disrupting the production flow. It uses machine vision to improve quality control in the automotive industry.

What is the challenge with inspecting glossy paint surfaces?

Eines Vision Systems' goal was to further increase the resolution and image quality of its already existing Esφi system for inspecting painted surfaces, without sacrificing speed. This is particularly important to many customers.

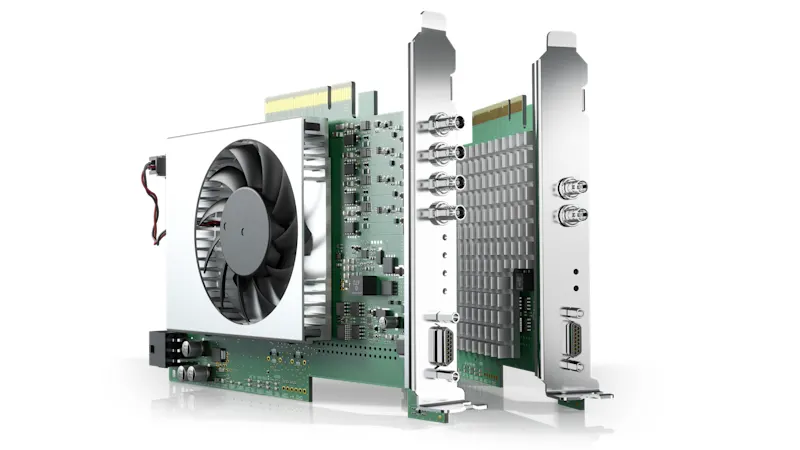

To meet the demanding requirements of the application, an image processing system solution with high-speed cameras and suitable lenses is needed. Interface cards are also needed to handle the high data, rates. These must work perfectly with the cameras to keep implementation effort and costs low. In short, Eines Vision Systems was looking for a CXP-12 solution with a software suite that allows easy installation.

The solution for defect detection on vehicle bodies

The Esφi vehicle inspection system uses Basler boost cameras (Basler boost boA4112-68cm) with CXP-12 Interface Cards and Basler Premium Lenses.

The cameras offer high resolution at a high frame rate, which significantly improves inline scanning performance. The Basler Premium Lenses are suitable for demanding applications like this one and ensure the best image quality thanks to very high resolution.

The CoaXPress 2.0 high-speed interface fully exploits the possibilities of modern image sensors, thus achieving maximum performance in the application. The interface cards used are an excellent match for the boost cameras, which reduces implementation effort and costs.

In addition, the pylon Software Suite is used, which enables easy image acquisition and camera control. All components are carefully tested and compatible with each other. This helps customers save time and money on their projects.

Advantages of the vision system for quality inspection of paint surfaces

Reliable and fast testing of paint quality

Seamless and optimal cooperation of the components of the entire vision system

Hardware, software and development from a single source saves effort, cost and time

Products for this solution

Looking to implement a comparable solution? These products will help you.