CMOS Rolling Shutter Cameras

The rolling shutter is an exposure method in which the sensor is exposed in sequential order, i.e. line by line. Important advantages of CMOS rolling shutter sensors are lower noise and lower heat generation. Many models of Basler ace, ace 2, and dart area scan cameras are equipped with sensors with rolling shutter technology. They are well suited for a wide range of machine vision applications.

Global Shutter vs. Rolling Shutter

When choosing a camera for an image processing system, not only are the resolution and speed decisive, but the exposure method—and thus the type of shutter—are also critical. Our white paper explains how global and rolling shutter work.

How does a rolling shutter camera work?

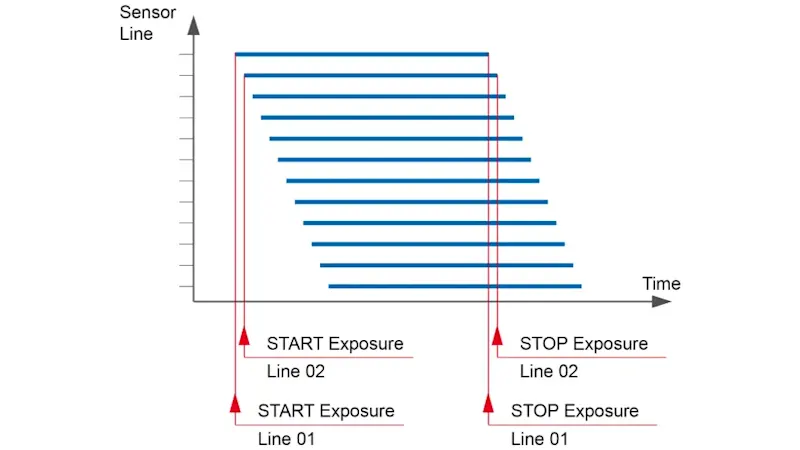

Rolling shutter technology is used in many digital camera sensors and image acquisition modules. With rolling shutter, the exposure of each pixel line of the image sensor is sequential. Depending on the type of sensor, this is done either from top to bottom or, in some cases, from left to right. With the global shutter, on the other hand, all pixels of an image sensor are exposed at the same time.

Line-by-line readout of pixel rows

Rolling shutter sensors read image data line by line. For efficiency reasons, there is a time offset between the start and end times of exposure for each line. This offset corresponds to the readout time.

This time varies depending on the sensor. With fast sensors, the time is shorter, and the time lag between lines is lower than with slow sensors. The lower the frame rate of a rolling shutter sensor, the more visible the distortions in moving objects become. With static objects, however, no such artifacts occur due to the lack of movement.

The advantages of modern rolling shutter cameras

The way the sensor surface captures and reads light information is different from that of a global shutter. The electronics controlling this process are simpler in rolling shutter sensors than in global shutter sensors. This means there are fewer components and a lower price. The smaller number of transistors also results in less heat and noise, which improves the sensor's sensitivity.

CMOS rolling shutter cameras are incredibly well suited for applications requiring enhanced sensitivity and image quality to inspect slow or stationary objects. In many cases, cameras featuring CMOS rolling shutter technology represent very strong value for their resolution. The smaller pixels often produce a very high resolution in a smaller sensor format.

What makes the rolling shutter unique

Rolling shutter sensors have the following advantages over global shutter sensors:

Good image quality due to low noise at higher resolutions

Cost and energy efficiency thanks to their simplified design

The rolling shutter effect

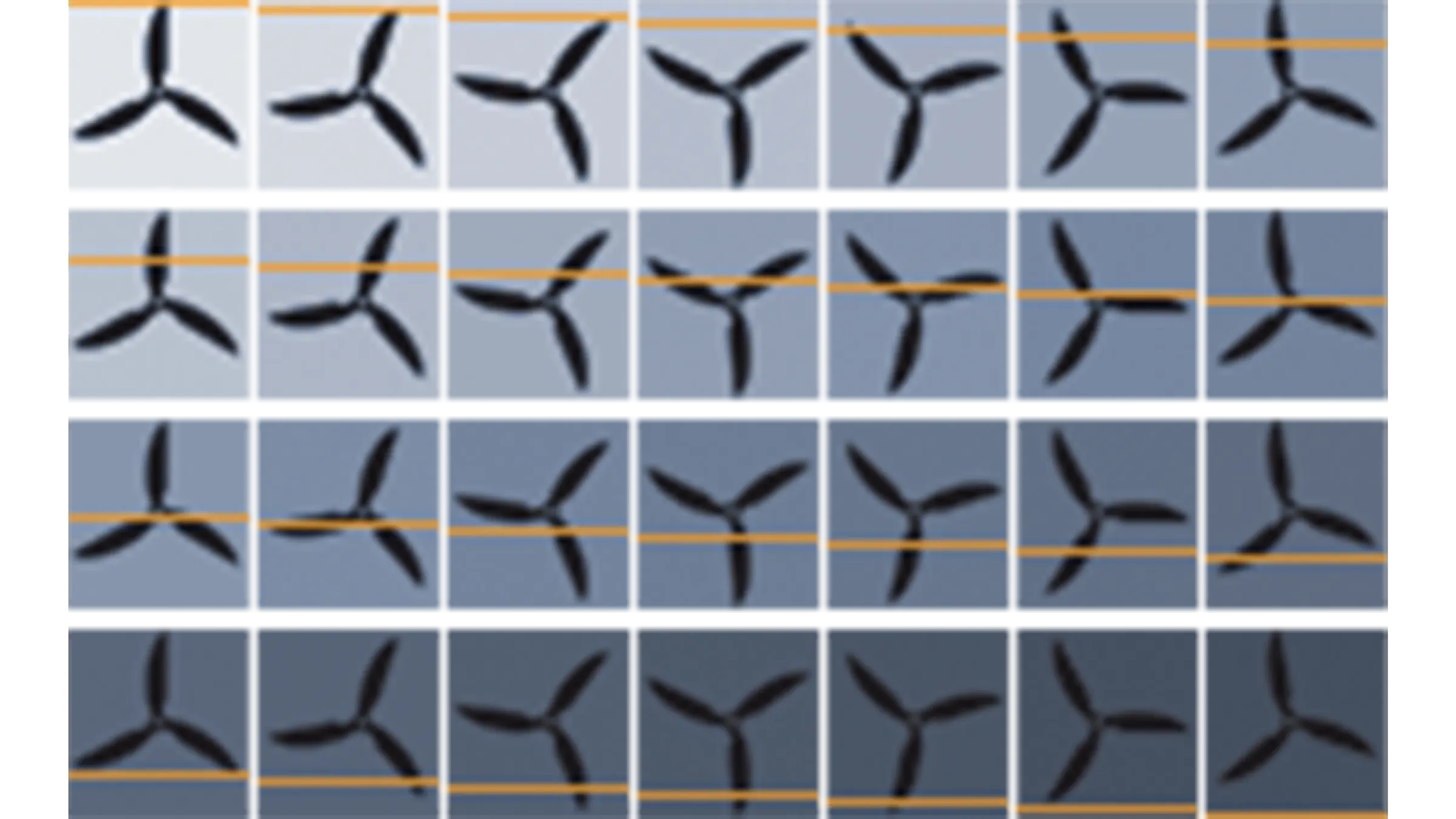

Due to the line-by-line exposure method, distortion can occur if the depicted object moves rapidly between the beginning of exposure of the first line and the beginning of exposure of the last line.

How the rolling shutter effect is created

When the image data is read out, the exposed lines are combined in the same order to form an overall image. Due to the time delay in the exposure of the individual lines, this temporal offset also becomes visible in the composite image in the form of distortions.

Situations in which the rolling shutter effect can occur

Depending on the frame rate of the sensor, slight to significant distortion may occur when shooting with a rolling shutter camera if the object or camera moves quickly.

Fast-moving vehicles: The wheels of a car, train, or motorcycle passing by at high speed can appear elliptical and the entire vehicle may look crooked.

Propellers and rotor blades: Rapidly rotating objects, such as helicopter rotors or aircraft propellers, may appear as bent strips instead of circular motions.

Objects on a conveyor belt: As part of quality control, defective or contaminated objects are detected and sorted out with the help of machine vision systems. In high-throughput factory applications, straight lines can appear slanted or curved, affecting the accuracy of results.

Running or fast sports: When filming people running or playing sports such as football, tennis, or other athletics, athletes' legs and arms may appear distorted and bent.

Panning the camera: When panning the camera quickly, for example when tracking a scene, straight lines (such as buildings or fences) may be displayed crooked and curved.

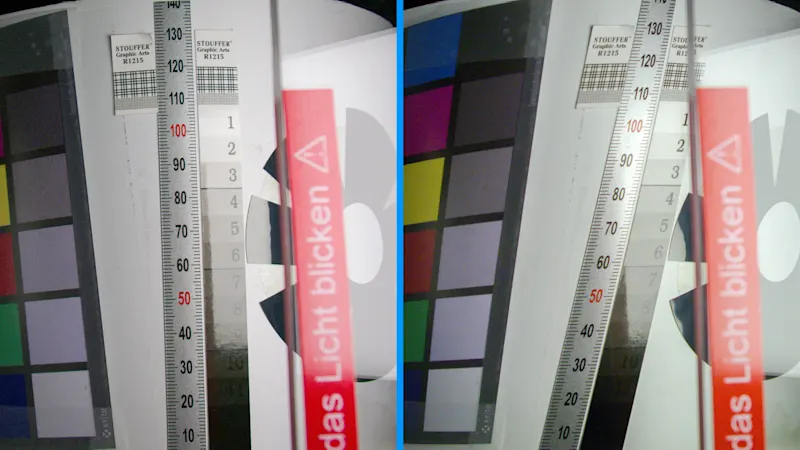

The influence of frame rate and exposure time

The decisive factor for the rolling shutter effect is the readout time of a line. A fast sensor with a frame rate of at least 60 frames per second tends to show less effect than a slow sensor with a maximum of 15 frames per second.

In general,

the higher the maximum frame rate of a sensor, the shorter the readout speed, and the lower the rolling shutter effect.

The exposure time, on the other hand, has no influence on the rolling shutter effect.

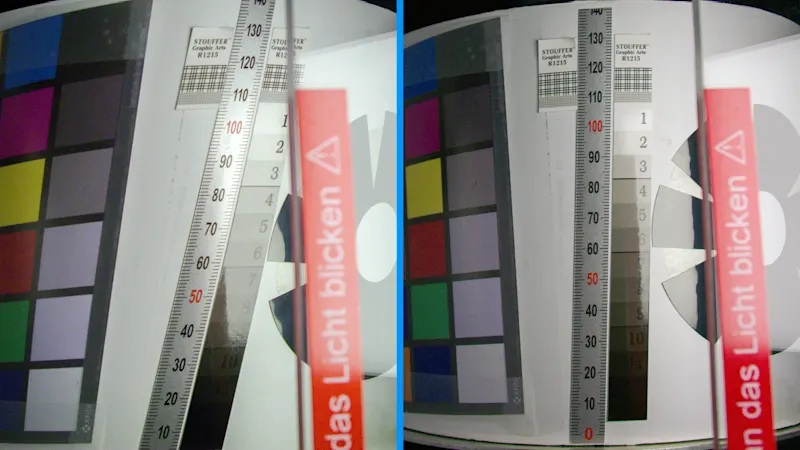

Counteracting the rolling shutter effect

There are several ways to minimize the rolling shutter effect:

Stacked BSI sensors

Modern stacked backside-illuminated sensors offer faster readout and can reduce the rolling shutter effect.Flash

A precisely triggered flash delivers an intense light pulse at the moment when all lines are exposed. Similar to the global shutter, the entire sensor surface is illuminated simultaneously.Software correction

Image processing functions can be used to minimize distortion and correct the rolling shutter effect.

Effect-related distortions can be completely prevented using a global shutter. This method of exposure - all pixel rows at the same time - prevents artifacts from occurring as in the rolling shutter effect. However, global shutter sensors are often more expensive than rolling shutter sensors.

Rolling shutter camera or global shutter camera?

This decision depends heavily on the specific requirements of your application.

To put it simply:

Rolling shutter cameras deliver excellent results with static inspection objects,

Global shutter cameras are the preferred choice for dynamic scenarios. They are ideal for fast motion sequences, such as object recognition on assembly lines in factory automation or automatic license plate recognition in traffic monitoring.