Solar Panel Inspection with SWIR Cameras During Operation

- Customer

- MBJ Solutions GmbH

- Location

- Ahrensburg, Germany

- Date

- 2025

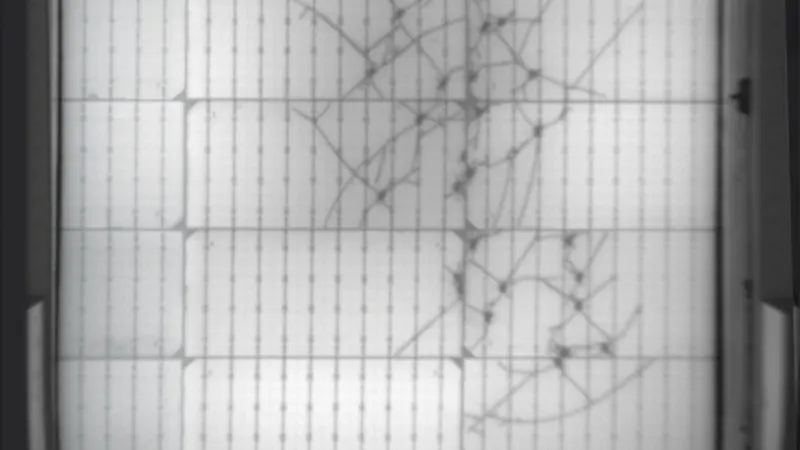

Hidden defects in the solar panels of a photovoltaic system reduce their performance and service life. Our ace 2 X visSWIR camera in MBJ's inspection system detects these defects by analyzing the light emission in the short-wave infrared range (SWIR). The solar cells are first excited with light. This method enables rapid optical inspection during operation.

Reliable performance thanks to regular solar panel inspections

Many environmental influences cause long-term defects in solar panels. If they remain undetected, they can lead to a loss of performance and therefore yield, as well as impairing operational safety. Regular solar panel inspections allow faulty modules to be detected and replaced at an early stage.

Why are SWIR cameras suitable for inspecting solar panels?

Solar panels are usually made of silicon. For their inspection, the luminescence behavior of silicon in the SWIR range is used: after electrical or optical excitation, the silicon solar cells re-emit some of the energy as electromagnetic radiation with a maximum around 1,150 nm. Because SWIR cameras operate in the wavelength range from around 900 nm to 1,700 nm, they detect this radiation. Since defects weaken or change the luminescence, the camera is able to detect microcracks and delamination (detachment of layers) as well as hotspots (local overheating), electrical malfunctions, and material differences.

What makes the MBJ Quickcheck special?

Common methods for inspecting solar panels are based on electroluminescence. To do this, installed solar panels must be dismantled or electrically disconnected. Voltage is then applied to each module to record electroluminescence images. Many inspections have to take place at night or under elaborately controlled lighting conditions. The inspection is therefore time-consuming and associated with yield losses.

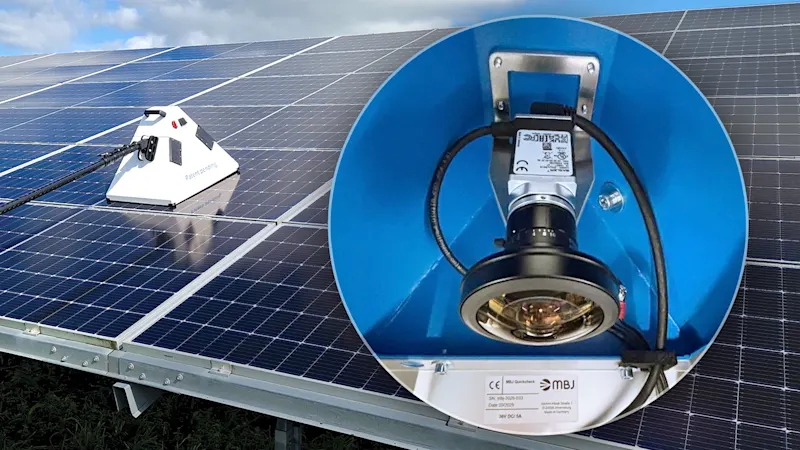

The MBJ Quickcheck system is a stand-alone imaging system based on photoluminescence. The LED lighting built into the housing exposes the solar cells to light. They absorb the energy, emit some of it, and the ace 2 X visSWIR camera captures photoluminescence images. The method makes it possible to inspect installed solar panels during operation and in daylight.

Thanks to our long-standing business relationship with Basler AG, we were able to test various SWIR camera models during development. Good advice from the technical support team combined with the usual high product quality tipped the scales in favor of integrating the Basler SWIR camera. In addition, Basler's software platform offered advantages, allowing us to design a compact system and develop the software quickly.

ace 2 X visSWIR camera captures the luminescence signal

To acquire photoluminescence images, the Basler a2A640-240gmSWIR is integrated into the MBJ Quickcheck system alongside the LED lighting, a bandpass filter, and a lens. The compact SWIR camera captures the luminescence signal.

Image acquisition at 1,150 nm, whereby the camera covers the visible and short-wave infrared range from 400 nm to 1,700 nm

Resolution of 0.3 MP. Many images of small solar panel areas result in a high resolution and therefore a precise analysis of the entire module.

Frame rate of 240 fps. This makes it possible to cleanly separate the signal from the background noise.

InGaAs sensor IMX991 of the SenSWIR series from Sony

GigE interface with a bandwidth of 1 Gbps

In-camera features for high image quality (Line Noise Reduction for a homogeneous background, Pixel Correction Beyond for dynamic defect pixel correction).

Learn more about our SWIR products

About MBJ Solutions

MBJ Solutions GmbH, based in Ahrensburg, is a leading provider of testing and measurement technology in the photovoltaic industry. For over 16 years, the company has been developing innovative systems for the quality assurance of solar modules - for maximum efficiency and long-term reliability of photovoltaic systems - and has already sold over 650 systems worldwide.