Fill Level Control of Opaque Containers with Classic Algorithms

A SWIR camera system and the pylon vTool Measurements software in use

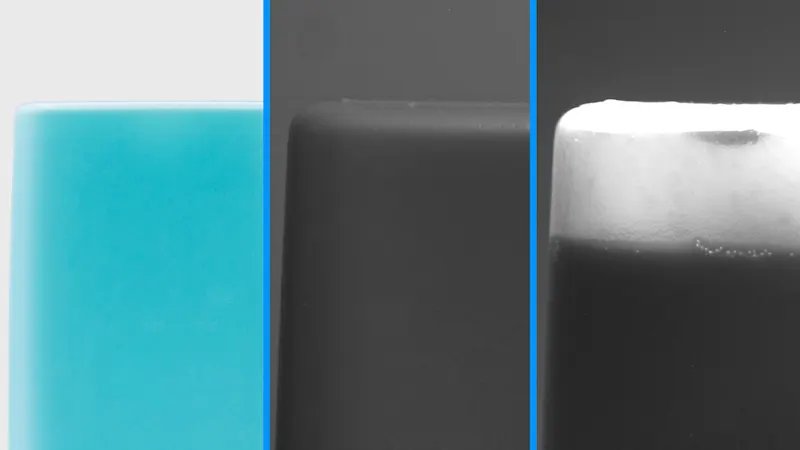

Correct fill levels are considered a quality feature. With SWIR technology, it is possible to look inside even opaque containers to check these levels. By combining classic algorithms that can measure and read the "edge" of the fill level with a simple image processing pipeline, successful quality control is achieved.

Fill level detection with a SWIR vision system and image analysis software

Precisely monitored fill levels are a criterion for both product quality and the smooth functioning of production processes. Modern machine vision technologies enable efficient and reliable optical inspection and level detection.

visSWIR technology provides images for quality control

The ace 2 X visSWIR cameras in combination with SWIR illumination deliver images in the visible and non-visible range. This vision system enables both optical inspection for defects and fill level control for opaque containers.

SWIR technology is well-suited for drugstore products and food sold in opaque plastic packages made of PET (polyethylene terephthalate), PP (polypropylene), or HDPE (high-density polyethylene). Tests have shown that most plastics and glass can be screened with SWIR technology for quality control purposes.

pylon vTools software: just two steps to detect the fill level

Using the Workbench and the function Camera vTool, the connected camera is controlled.

The pylon vTool Measurements is configured to find the surface of liquids, viscous products, or even powders by searching for the strongest edge in the defined measurement region. By defining the reference position via Positions_px, the deviation from the reference position can be measured.

Metric units instead of pixels

By default, image analysis software measures distances and positions in pixels, since it can only access the image information. However, the pylon vTool Calibration & Rectification enables a calibration that replaces the pixel-based measurements of positions and distances with measurements in meters.

To expand your image processing pipeline accordingly, simply add the pylon vTool Calibration & Rectification before the pylon vTool Measurements.