Pharmaceutical Industry

Vision solutions with speed and precision

The pharmaceutical and medical device industries are subject to strict regulations. Whether for labeling, content or material, camera-based inspection systems provide the speed and accuracy essential for 100% inspection during and after production to meet quality standards and regulatory requirements.

High performance & speed

Innovative, high-performance camera technology for state-of-the-art production methodsCustomizable hardware and software

Our project teams work with you to design tailored solutions that meet your lab’s specific needs.Industry-leading reliability

Basler cameras have one of the lowest failure rates in the industry — built for continuous, 24/7 operation.Availability & reliable delivery

Stable supply chains ensure long-term availability of our products and prevent production downtime

Typical areas of application in the pharmaceutical industry

Vision systems in the pharmaceutical and medical device industries check whether, for example, labeling and package contents match, package inserts are present, quantities are correct, or defects and material flaws are present. Basler's vision solutions offer the high resolution and fast image transmission rate required for this.

Production control

Camera systems are used in various production steps. They take over the completeness and placement control, the control of separation and selection, the assurance of traceability as well as the serial number coding, application, inspection and recording. And all this in manufacturing processes with a very high speed.

Quality control

The areas of application for vision solutions in quality control include inspection for completeness, dimensional accuracy and material defects as well as other types of defect. The optical inspection system must keep pace with the fast-paced manufacturing process and operate reliably even at high speeds.

Recognition of text, bar and matrix codes

In code recognition, camera systems are used to capture a wide variety of codes, such as Data Matrix codes, but also color codes and plain text (OCR/OCV optical character recognition or verification). A special challenge is presented by the often transparent backgrounds.

How our customers achieve more

Discover how industry pioneers in the pharmaceutical sector are overcoming complex challenges and unlocking new levels of efficiency and accuracy—with the power of our machine vision technology.

Automated inspection of COVID-19 vaccine vials

Automated inspection systems for injection vials monitor the product quality of vaccines and play a critical role in ensuring maximum product safety. Advanced vision technology helps to eliminate errors, improve quality, and increase yield.

Read the full storyPrecise inspection of mouth/nose protection masks

The intelligent inspection system for mouth/nose protection masks developed by the company automates manual quality checks that tend to be lengthy and error-prone. The 100 % automated visual inspection in the production process increases the productivity. It also ensures the product conformity and detection of rejects.

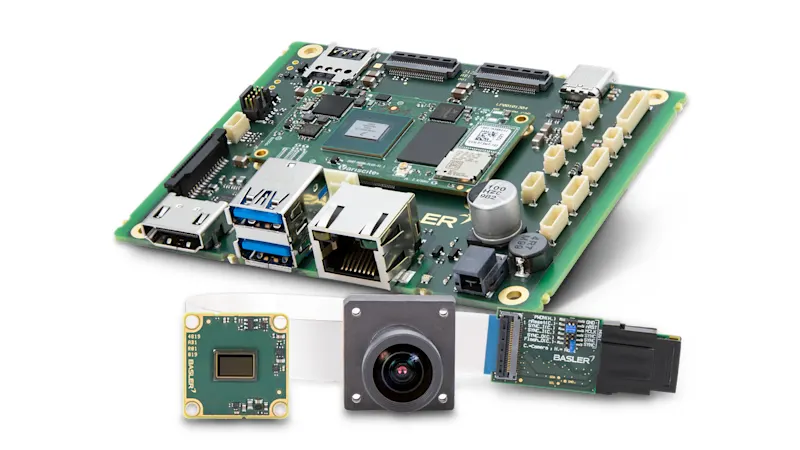

Read the full storyMost popular products

For efficient and reliable machine vision applications in this industry, the following Basler products are often the best choice: