Finding and Reading Small Data Matrix Codes and Barcodes on Large Areas

What is the automated finding and reading of barcodes all about?

In the production, packaging and shipping process, 1D and 2D data matrix codes and barcodes are used for traceability. The small codes must be found and read automatically on large packages.

Challenges in reading small barcodes on large outer packages

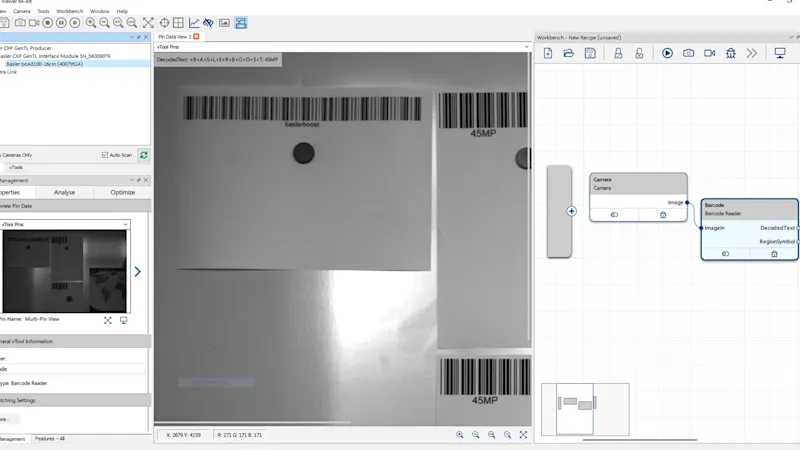

Searching for codes on large pallets can be particularly difficult: Codes are often aligned at different angles to the camera. Small codes appear on both individual product packaging and larger outer packaging. Multiple codes may appear on any given package. Cameras must cover a large target area while detecting much smaller packaging and codes.

All packaging and codes need to be recorded in a single pass and analyzed for final quality inspection.

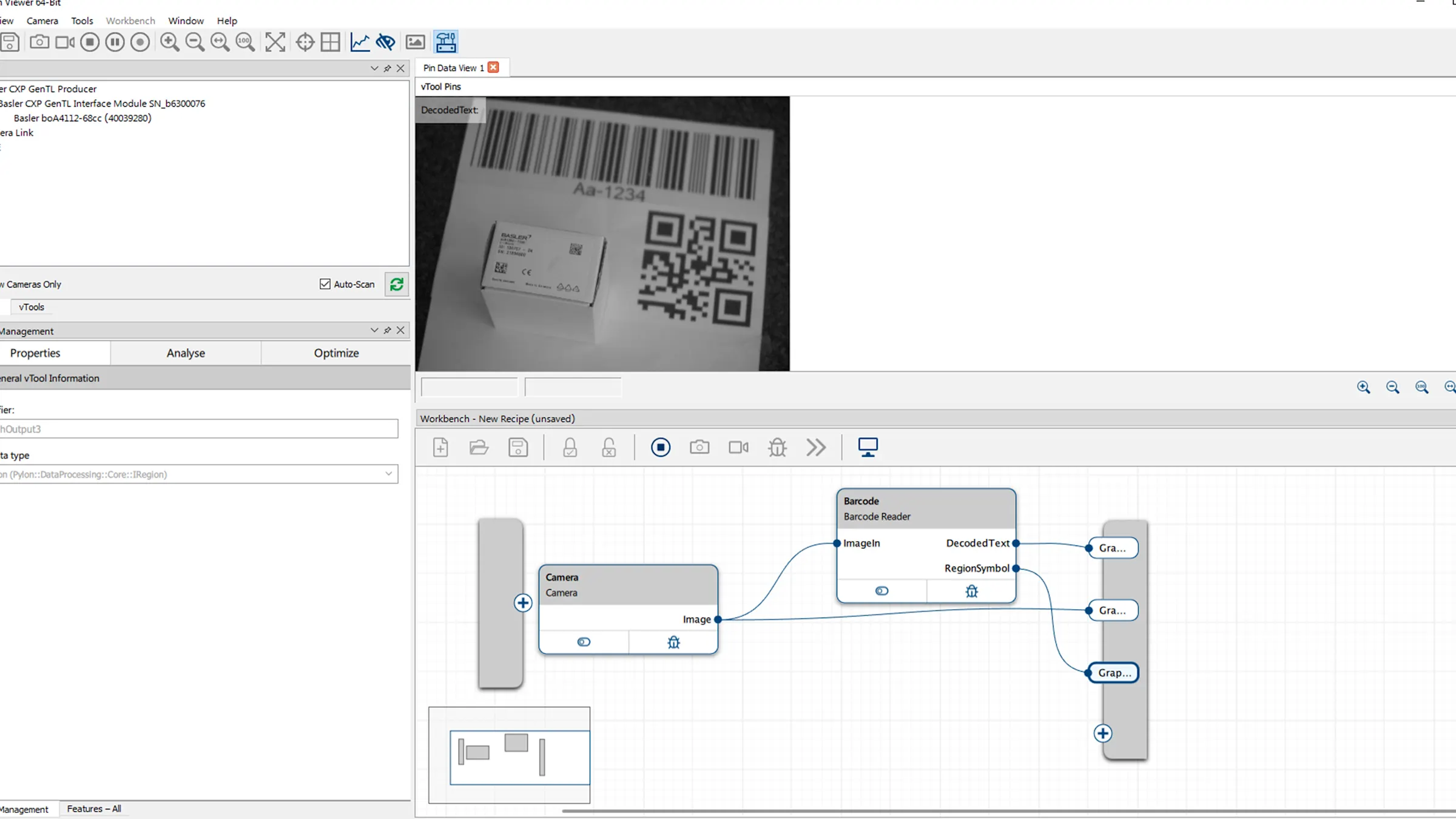

Reading barcodes with high-resolution cameras and software modules

Solving this problem requires a vision system with a large field of view, low latencies, and high data throughput—achieved by combining Basler’s boost cameras with onsemi’s high-resolution CMOS sensor (XGS 45000, up to 45 MP, global shutter), and CXP-12 interface.

The large, definable field of view (ie: 2 m by 1 m) and 45 megapixel high-resolution allows this system to record large packaging down to the smallest code label with exceptional accuracy per pixel. Even the narrowest lines of the data matrix code are sharply reproduced with an accuracy of four pixels.

Additional system components include Basler lenses, an acquisition card (for example: the single-channel CXP-12 interface card) and Basler’s pylon Camera Software Suite.

Your benefits from computer vision for code search on packaging

Simple and reliable capture of small barcodes across a large area

Transfer large amounts of data with low latencies at very good image quality (high resolution)

Time and cost savings – pylon Camera Software Suite as single SDK reduces system complexity with plug and play setup

All vision components are tailored for compatibility to ensure high quality, reliable results

Products for this solution

Looking to implement a comparable solution? These products will help you.