Automated Inspection of COVID-19 Vaccine Vials with Basler Cameras

Automated inspection systems for injection vials monitor the product quality of vaccines and play a critical role in ensuring maximum product safety. Advanced vision technology helps to eliminate errors, improve quality, and increase yield.

What is vial inspection?

Truking Technology is a leading pharmaceutical equipment supplier with over 20 years of experience in healthcare packaging and various automation systems for the biopharmaceutical industry.

The coronavirus pandemic spurred a global collaboration on vaccine research and distribution that resulted in a vaccine in less than a year. But a vaccine is only effective if people can get it, and supply chains were put under pressure to meet this sudden, unprecedented demand for vaccines.

To support the fight against the pandemic, Truking Technology is committed to providing automated visual inspection systems to quickly ensure vaccine safety and product integrity.

Injection vials are used to store the liquid vaccine.

The challenges of automated vial inspection

Glass vials are used to store the liquid vaccine and during the massive filling work, it is inevitable that defects in filling and sealing will happen. Various visual inspections are required to assure that vials contaminated or with defects are excluded from the batches. Some of the inspection tasks include:

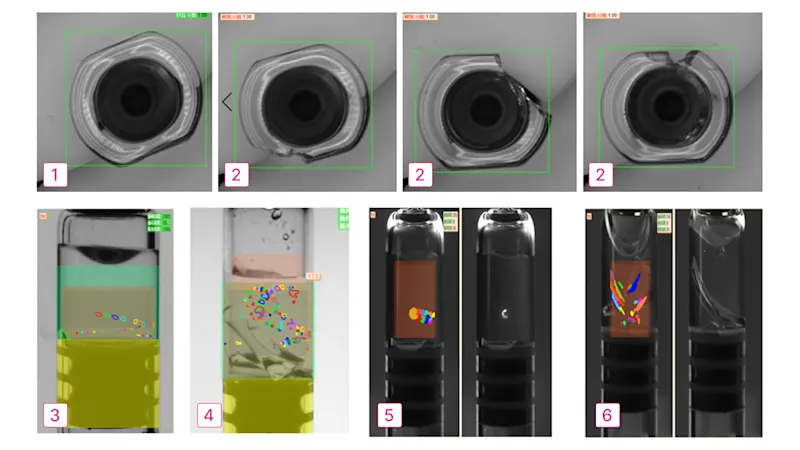

To identify any foreign bodies, glass particle, fibre-like material, etc. in the vials

To check the presence/absence of vial cap and flip-off seal, the position of the cap, and the filling level

To detect cosmetic and functional defects of the vials

Key challenges in the inspection tasks are:

Adding up all of the dimensional, physical and cosmetic features, the system needs to inspect many attributes in a very compact space.

Detecting defects from cylinder surfaces with a vision system is difficult. The vials are transparent, filled with clear liquid and moving; they have bubbles inside them and they are reflective.

High speed, accuracy and stability is required.

Inspection solutions with area scan and line scan cameras

Truking Technology develops various automatic glass vial inspection systems for different tasks. Hardware combinations of camera, lens and cable are used. Two such inspection solutions are described below.

1. Inspection system with area scan cameras in a multi-camera setup

Main tasks:

Vaccine liquid inspection and vial cosmetic inspection

Configuration: 16-20 pcs Basler ace acA1300-200um area scan cameras

Sixteen to twenty high-speed cameras are installed in the inspection system to acquire image sequences of different parts of vial batches, providing basis for image analysis. The multi-camera system is able to judge if a product is good or defective by comparing multiple images using its powerful vision software. The advanced vision algorithm and deep learning algorithm is able to identify contaminations and defects.

AI supports detection of defects

An AI algorithm is used to learn the movement of bubbles in order to distinguish bubbles from foreign objects, including glass particles, metal grains, fibers and hair, in the vaccine liquid. Fill levels are also checked.

At full resolution, the acA1300-200um camera works at 200 frames per second, reaching even higher acquisition speeds in ROI mode.

Multi-camera system with precise synchronization

Truking's inspection solution uses multiple cameras to acquire images from different angles simultaneously, significantly increasing inspection efficiency and accuracy. Basler's market-proven multi-camera setup with USB 3.0 interface is ideally suited for such a solution and offers the advantages of high efficiency, perfect synchronization, and high reliability.

2. Inspection system with line scan cameras for moving objects

Main tasks:

Vial surface cosmetic inspection

Configuration:

2 pcs Basler racer raL2048-200um line scan cameras + FA lenses

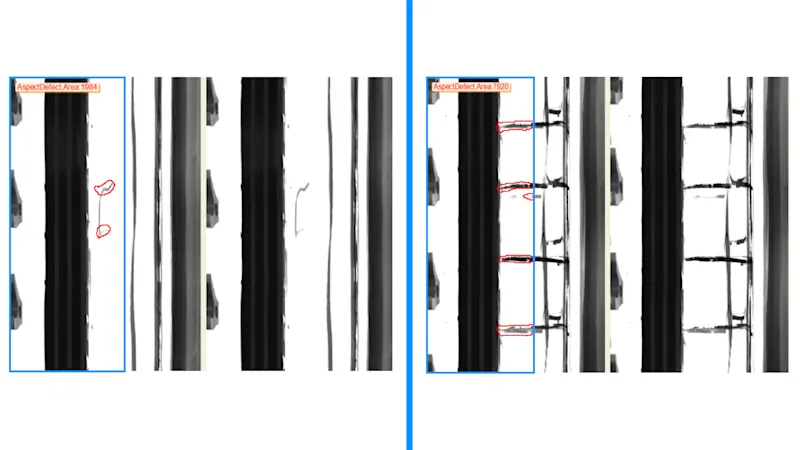

The second inspection system is equipped with two high-resolution line scan cameras and FA lenses, as well as specially designed lighting arrangements. It inspects for cosmetic defects on the cylindrical surface of the vial, including cracks, scratches, refractory stones, and black spots.

Line scan vision inspection is an ideal choice for imaging cylindrical objects on fast-moving inspection lines. As the vaccine vial rotates, the line scan camera examines and unrolls the entire surface of the vial, line by line, into a 2D flat surface for inspection.

Automation to ensure reliable fault detection at high speeds

Replacing human visual inspection with automated inspection systems in the biopharmaceutical quality control process is now commonplace, as the latter provides far greater efficiency and accuracy of inspection results. The key objectives in glass vial inspection for COVID-19 vaccines are to provide error-free quality assurance with speed. Truking's inspection solutions utilize advanced vision algorithms and AI technology to ensure inspection efficiency and accuracy.

Truking is committed to delivering high-performance inspection systems to our customers ahead of schedule. We are racing against time in such crises. The most important reason for us to collaborate with Basler is excellent stability, especially in multiple high-speed cameras with USB3.0 interfaces set-ups. Basler is a market leader and has rich experience in such set-ups. Their expertise helped us to reach our goals. Ease-of-use software is also critical for us to achieve fast development. The pylon Camera Software Suite is easy to adapt to and functions seamlessly, saving us precious development time. Besides, the excellent and timely service and support by the local team makes our partnership a great success.

Products for this solution

Looking to implement a comparable solution? These products will help you.