Lean Product Design

We develop the design of our products in line with the wishes and requirements of our customers. We reduce planning effort and avoid wasting resources throughout the entire development process.

Lean Design in our company

We develop a clear product that is reduced to the essentials. It functions efficiently, without superfluous ballast and fulfills all necessary requirements. Lean Design principles accompany our products from the initial idea right through to life cycle management.

Customer centricity

Lean Design helps us to design a new product in such a way that it meets the customer's requirements. Because we listen carefully, our products always meet their real needs and are easy to use and integrate.

We select development processes that are efficiently and effectively aligned with the project objective. These can be standard applications or individual customer projects. Sometimes our customer is even part of the project team.

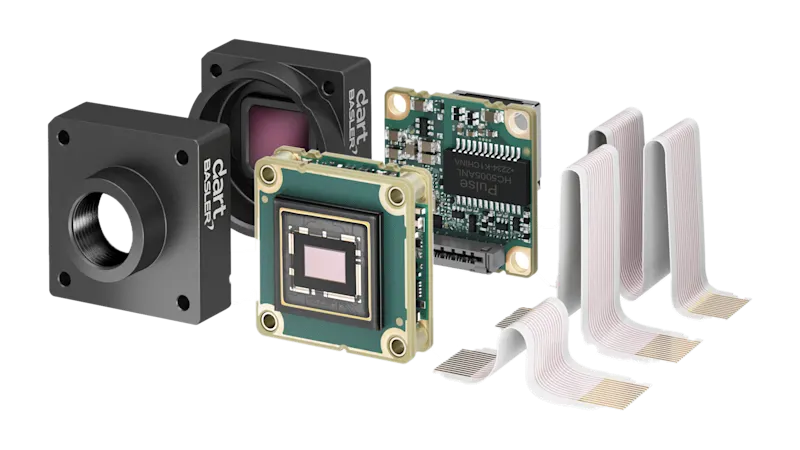

Modular product design

The modular approach in Lean Product Design allows changes to be made to individual modules without any significant impact on the rest of the system. This increases the speed of adjustments and saves valuable time, resources and manpower.

Thanks to its consistently modular structure, the entire platform architecture enables the sustainable reuse of modules. This speeds up processes and reduces costs for the benefit of our customers.

One example of this is the dart M: a modular board-level camera with a GigE interface that our customers can assemble according to a modular principle to meet their exact requirements.

This sustainable, resource-conserving approach is one of the main reasons for ouroutstanding price-performance ratio.

Lean Designaccompanies our products even after market launch. Systematic life cycle management ensures ongoing optimization and thus reliably ensures long-term availability.

Employees as a success factor

Our employees are a key element of our success with Lean Design projects. They not only contribute their knowledge and expertise to the interdisciplinary development teams, but also their enthusiasm and passion.

For standard products, they work together in core teams across several projects. They are supported by experts as required, allowing us to continuously build up knowledge across several product generations. For more complex customer projects, we put project teams together flexibly so that they are always optimally positioned, even when skills requirements change.

In the background, specialists provide the necessary infrastructure so that the development teams can focus on the content of the product development projects.