ID Reading and Traceability in Semiconductor Manufacturing

Overcome low contrast and surface variability to maximize ID reading accuracy

Traceability is critical in semiconductor manufacturing. Basler’s solutions enable accurate ID reading—from wafer edge OCR to FOUP barcodes, reticle IDs, substrate codes, and carrier ring markings—ensuring reliable tracking across all stages.

Precision traceability from wafer to final package

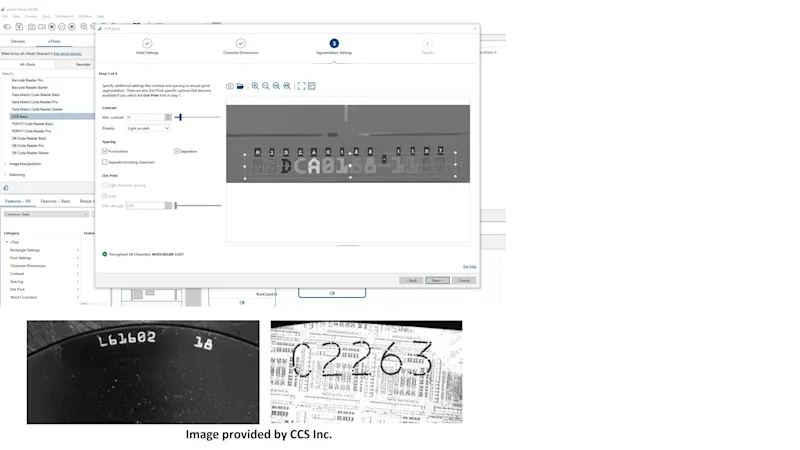

Throughout the semiconductor manufacturing process, identification markings must be reliably read to maintain complete traceability. These markings include barcodes, OCR codes, DataMatrix codes, and QR codes that can be laser-etched, dot-peened, or printed on various surfaces with different optical properties.

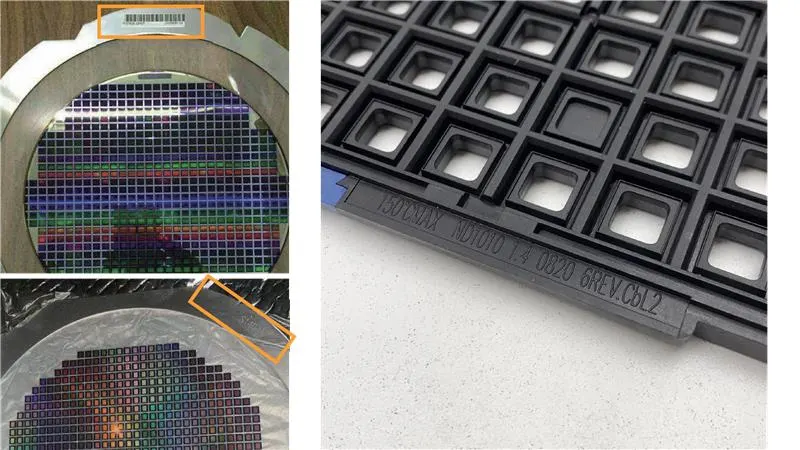

Wafer and reticle ID reading

Wafer edge OCR involves reading small alphanumeric characters laser-marked on the outer edge of a silicon wafer. These unique IDs typically follow industry standards such as SEMI M12 or T7 and are essential for traceability throughout the manufacturing process.

Reticles, or photomasks, contain the circuit pattern for each chip layer. A laser-etched ID on the glass or chrome border ensures proper usage and traceability during lithography.

Carrier ring and chip tray reading

Post-dicing, wafers are transferred to carrier rings or substrates for downstream processes such as die attach, wire bonding, and packaging. These components are marked with process-specific IDs that enable traceability of individual dies or batches during handling and assembly. However, reading these IDs reliably poses unique vision challenges due to material properties, surface wear, and environmental variability common in back-end environments.

Basler’s integrated vision solution for semiconductor ID reading

Basler offers a configurable vision solution for semiconductor ID reading, designed for easy integration into inspection, dicing, and handling systems. It combines four critical components—high-performance cameras, optimized optics, adaptable lighting, and intelligent software tools—that work together to deliver flexible, reliable performance for wafer edge OCR, carrier ring codes, and substrate IDs. This integrated approach ensures consistent results across a wide range of materials, lighting conditions, and process environments.

Recently, more customers have adopted advanced multi-angle imaging strategies inspired by photometric techniques, yet differences in system design, software integration, and implementation methods continue to create challenges.

Want to see how to solve these ID reading challenges?

Facing low contrast, glare, or curved surfaces?

Unlock a concise, technical reference table that maps real-world challenges to tested solutions, including lighting, optics, and software configuration.

Submit to access the full guide.