Quality Assurance of the Basler dart Camera

Seamless control with AI

Small, precise, varied: the Basler dart camera places high demands on assembly. Thanks to AI-supported image processing, the final assembly step can be checked automatically - in real time. The result: maximum quality with a minimum error rate.

AI as a tireless assembly inspector

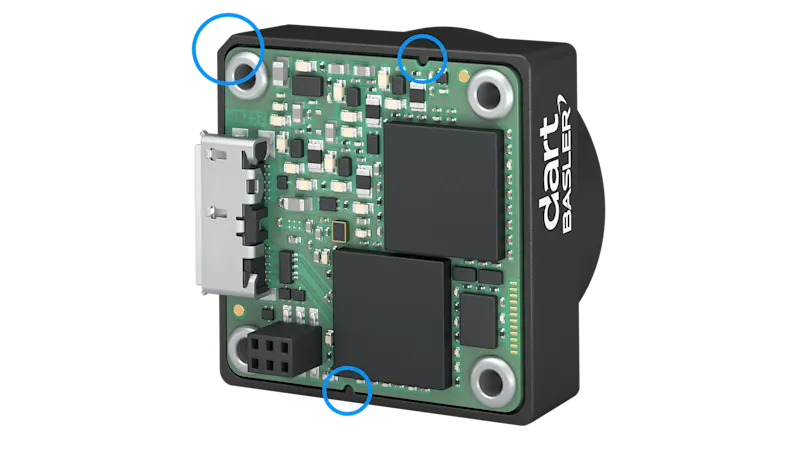

The dart USB 3.0 camera is a board-level camera that is supplied in S-mount or CS-mount housing variants. For variants with a mount, the sensor board is inserted into a camera housing and riveted. Incorrect positioning leads to malfunctions and complaints.

Order-related, manual final assembly

Cameras are assembled according to the customer's order. For orders with housing, an additional assembly step with riveting is required. Several alignment features are used to correctly position the camera board in the mount:

Two lugs on the housing clearly fit into two recesses on the camera board.

One of the four corners of the housing is beveled.

Miniature camera, big challenge: precise assembly of the dart series

Due to the compact dimensions of the dart camera at just 29 mm × 29 mm, the fitting features are very small and difficult to see with the naked eye: The lugs and recesses are smaller than 1 mm, and the beveled corner is minimally pronounced. Although the error rate is less than 1%, assembly errors cannot be completely ruled out.

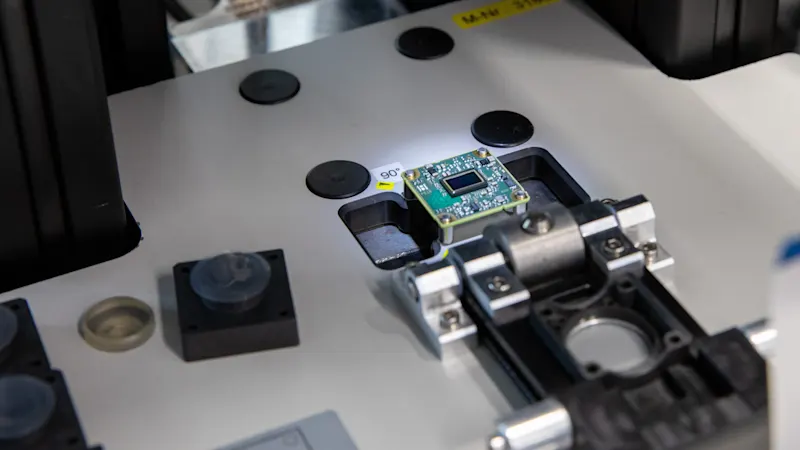

A dart camera monitors dart cameras

Camera selection: Optimized for AI

In this case, our camera model is suitable for automated, visual inspection daA720-520um (CS-mount).

The resolution of 0.3 MP is deliberately low to enable easy, real-time AI processing.

The selected ROI of 500 px × 500 px (≈ 45 mm × 45 mm in reality) provides just enough detail (11 px/mm) to recognize the quality features.

Therefore, no high-performance hardware or GPU is required; the QA system can be run embedded or on edge devices.

On the way to a 0% error rate thanks to AI

An AI-based vision system can take over quality assurance at the assembly station in the future:

The dart camera daA720-520um (CS-mount) is installed at a working distance of 650 mm above the workstation.

With the help of the pylon vTool Anomaly Detection the fitting characteristics are checked automatically.

The results of the anomaly detection are displayed on a screen in real time.

If the AI reaches a probability of 70% or higher for a potential deviation, a visual warning may appear. This would inform the employee to check the assembly again

Products for quality assurance

With these products, you get everything you need to get started quickly with AI-supported image processing: a high-quality camera, the right lens, adapters, and powerful AI software.