Reliable Inspection of Contact Lenses in Blister Packs Using SWIR Technology

Contact lenses require flawless quality to ensure user safety and comfort. Basler’s ace 2 X visSWIR cameras deliver precise inspection through transparent blister packaging and saline solution, detecting even the smallest cracks, bubbles, or contamination. With exceptional sensitivity across the visible to SWIR spectrum, they enable reliable, high-throughput inspection that ensures every lens meets the highest medical standards.

Inspection challenges: When transparency becomes the obstacle

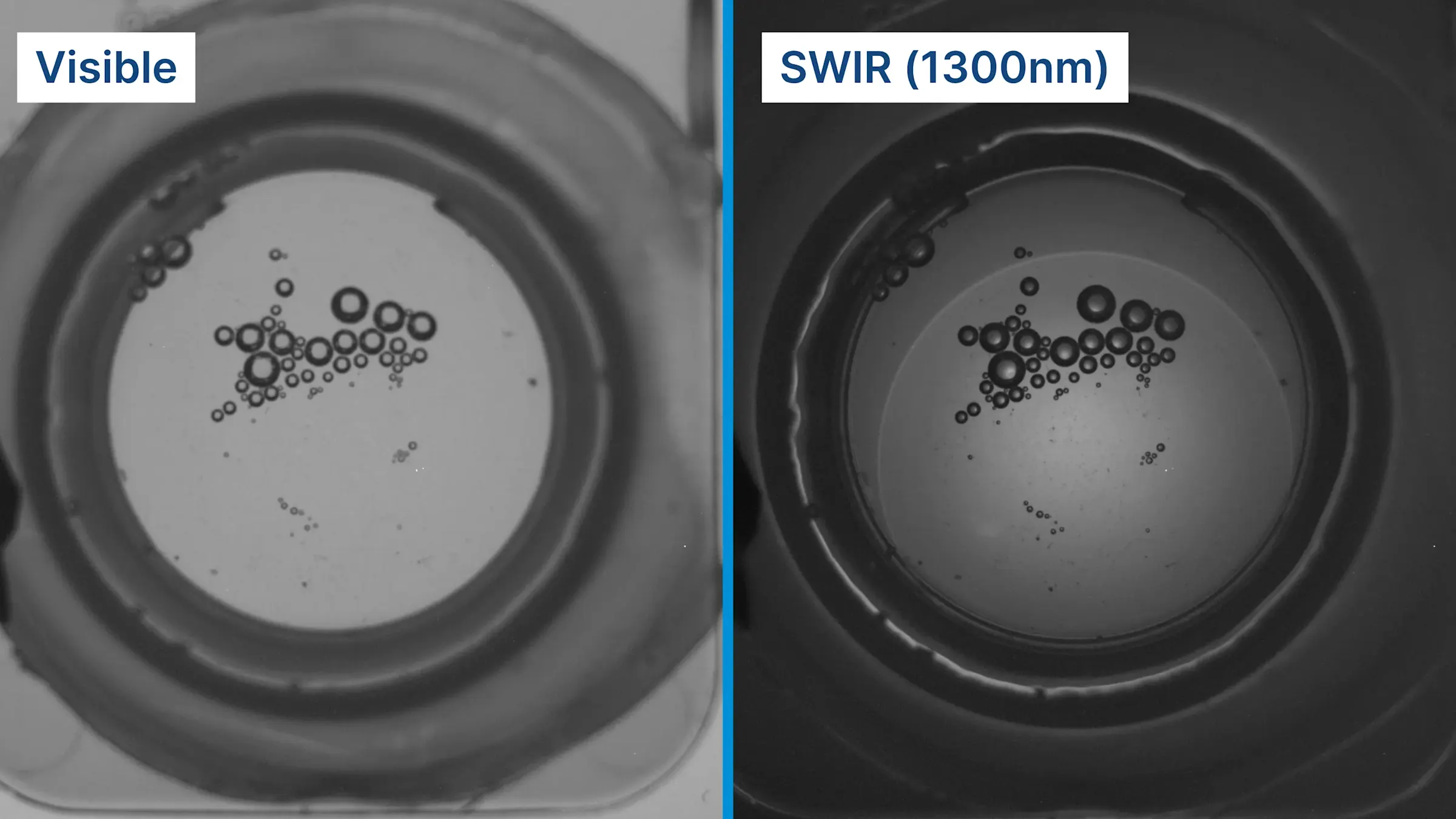

Contact lens blister inspection is one of the most complex vision tasks in medical device manufacturing, as it involves multiple transparent materials (the contact lens itself, saline water, air bubbles, and a clear plastic blister cover). These elements interact optically, creating unpredictable reflections, scattering, and contrast loss. As a result, conventional visible cameras often struggle to deliver reliable detection.

Low contrast between transparent materials

In visible or near-infrared imaging, water, air, and the polymer lens all appear similar in intensity and texture. The edges of the lens often blend into the background, making it difficult to determine its contour or orientation. Even small shifts in illumination or camera angle can cause the lens outline to disappear completely. This lack of contrast prevents accurate differentiation between materials and leads to unstable inspection results, especially in high-speed production lines.

Water absorbs more strongly in the SWIR spectrum, creating a natural contrast separation that clearly defines the lens against the saline solution. This enhanced material differentiation provides stable, repeatable detection of lens boundaries, even under fast-moving or variable lighting conditions.

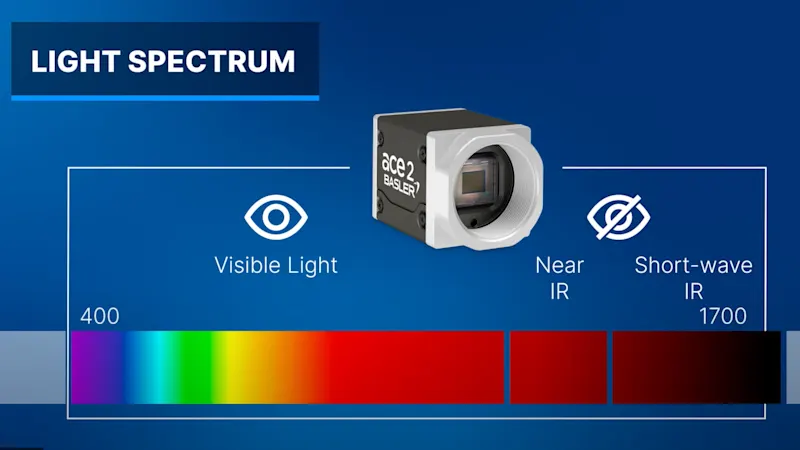

Seeing beyond the limits of visible light

Unlike conventional visible or NIR cameras that rely on reflected light in the 400–1000 nm range, SWIR imaging operates across a broader 400–1700 nm spectrum — where light interacts differently with materials such as water and silicone hydrogel. In this region, SWIR wavelengths penetrate translucent and reflective surfaces, revealing subsurface features that standard imaging cannot detect. This unique spectral behavior allows SWIR cameras to exploit the varying absorption properties of water and polymers, creating strong natural contrast even through saline-filled blister packs. As a result, defects like fine scratches, micro-cracks, and air bubbles become distinctly visible without complex lighting setups. With faster signal response and reduced glare from specular surfaces, SWIR imaging delivers sharper, more stable images — enabling precise, real-time defect detection and streamlined inspection in high-throughput contact lens production.

Contact lens AOI is challenging due to low contrast in saline blisters and hidden micro-scratches. We work with customers to test SWIR wavelengths, optics, and illumination, enabling reliable, high-speed inspection and faster integration of the right vision setup.

ace 2 X visSWIR camera models

Find the right camera for your application or use our Vision System Configurator to configure your system.