Compact Scheimpflug Imaging Solution for Complex 3D Structure and Extended Depth of Field

From early testing to deployment, a custom solution for simplified integration

Maximizing inspection efficiency for slanted, raised, or complex surfaces often requires Scheimpflug imaging to extend usable field of focus. Yet integrating this technology—which spans optics, algorithms, and mechanical design—can be challenging. Our compact, customized solution combines FPGA‑accelerated processing algorithms and seamless mechanical design to simplify integration from concept validation to deployment.

Why Scheimpflug imaging?

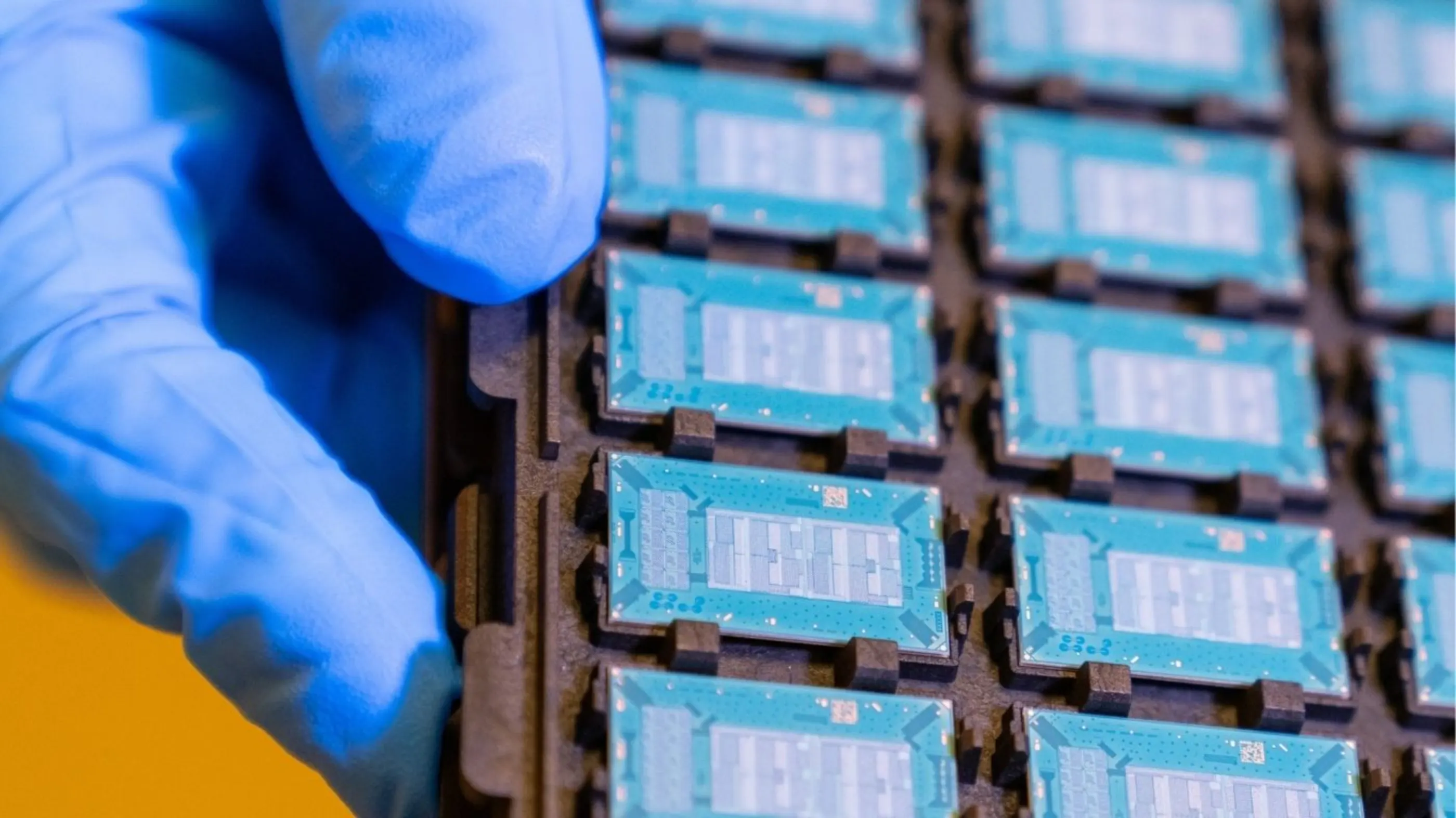

In machine vision inspection, objects often have 3D structural features such as slanted or uneven surfaces, vias or grooves, and critical sidewall details that traditional top‑view imaging can miss. Scheimpflug imaging enables the focal plane to align with the tilted object surface, allowing AOI systems to capture more in-focus details across the field of view.

This capability is critical for advanced manufacturing processes—from semiconductor packaging inspection to PCB quality assurance and display panel defect detection.

Overcoming key integration challenges

Scheimpflug imaging improves inspection efficiency and detail at tilt angles, yet effective deployment requires addressing optical alignment, algorithm optimization, and full system integration challenges.

Extended Depth of Field: NA adjustment combined with Scheimpflug

Reducing the numerical aperture (NA) is a common approach to extending depth of field, but it often comes at the expense of resolution and contrast.

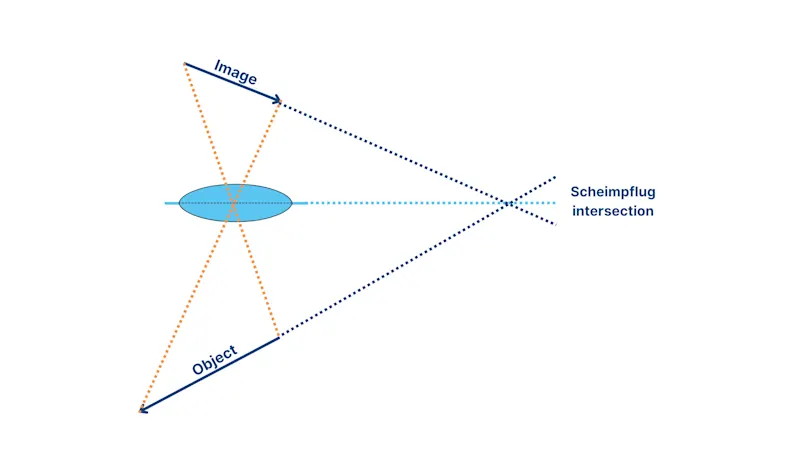

A system configured using the Scheimpflug principle tilts the focus plane to align with the object’s surface geometry. While this doesn’t increase the theoretical depth of field, it keeps more of the target in focus—particularly for slanted or uneven surfaces—creating the practical effect of extended depth of field.

Scheimpflug imaging is a valuable technique that helps offset NA-related trade-offs in certain applications.

Distortion correction: real-time algorithmic compensation

Tilted viewing introduces strong perspective effects, resulting in trapezoidal distortion where nearer objects appear larger and farther ones smaller. This distortion directly impacts measurement accuracy.

Our real‑time distortion correction algorithms map image coordinates to physical coordinates, eliminating perspective distortion and restoring true geometric proportions. Additionally, radial lens distortions are also corrected, delivering subpixel accuracy with processing times under 5 ms, supporting real‑time inspection.

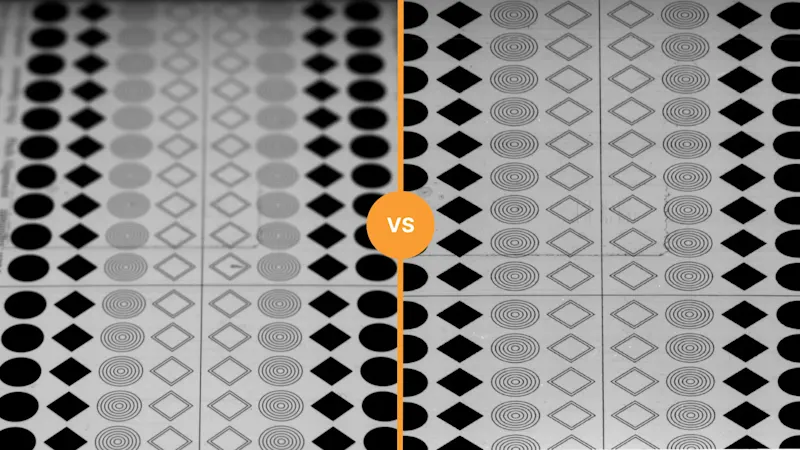

Contrast enhancement: 80% uniformity improvement algorithm

Scheimpflug imaging can reduce edge contrast due to lens aberrations, tilt angle light variation, and sensor angle effects. Our FPGA-based algorithm adjusts gain in different image regions using a quality distribution map. This improves contrast uniformity by 80%. Edges stay sharp, noise is reduced, and image quality remains consistent across the entire field of view.

Facing image processing challenges with Scheimpflug design? Let's talk.

FPGA preprocessing: no added CPU load

To prevent image preprocessing from affecting main CPU performance, we implemented distortion correction and contrast enhancement entirely on FPGA hardware. FPGAs’ parallel architecture naturally suits image processing, achieving speeds 10–50× faster than CPU-based methods. Moreover, its pipeline architecture provides true zero-latency processing, performing all preprocessing as the image data streams through.

This allows the main CPU to focus entirely on inspection algorithms, maximizing overall system efficiency. FPGA power consumption is also highly optimized, consuming only one-tenth of GPU power for the same processing capacity, which is economically advantageous for long-term industrial operations.

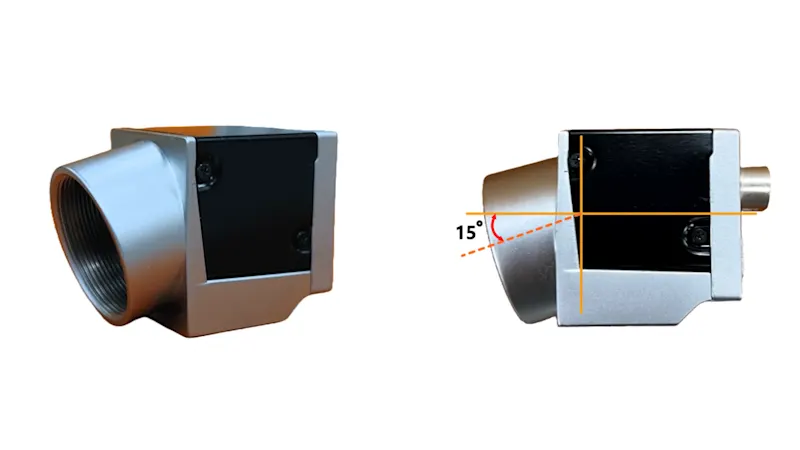

Rapid angle testing: dedicated hardware design

Finding the optimal tilt angle is critical yet time‑consuming. Our custom lens mount hardware enables flexible adjustment with a built‑in degree indicator, accelerating prototyping and integration. The clear scale ensures intuitive and repeatable angle setting, while standardized interfaces ensure compatibility with mainstream cameras and lenses—ideal for lab testing and determining the optimal tilt angle before finalizing production designs.

Compact tilt mount camera solution

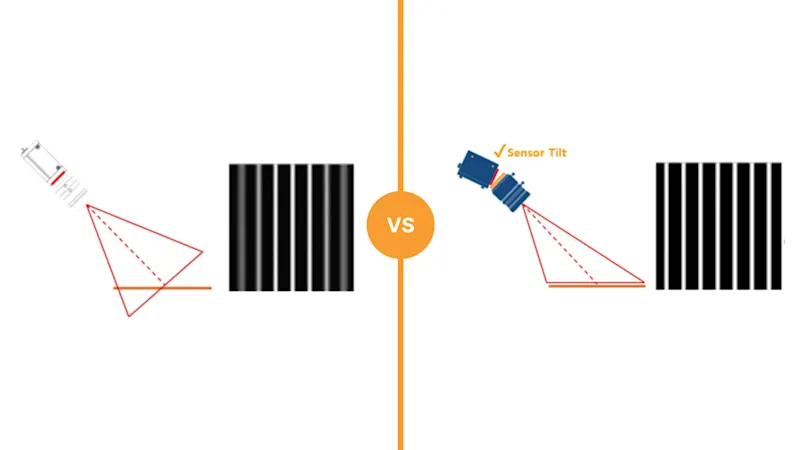

In actual system integration, Scheimpflug imaging often faces alignment challenges and added mechanical complexity. This is mainly due to conventional camera housing limitations, especially in screen printing inspection and flat object scanning where nonstandard tilt angles are required.

Our tilt mount camera solution integrates a fixed Scheimpflug angle directly into a compact housing with optimal sensor plane alignment—eliminating bulky external mounts and complex alignment steps. This design simplifies mechanical integration, enhances stability, and reduces overall system size by up to 30–50%, making it ideal for both prototyping and production environments.

Need a custom tilt camera mount? Let’s discuss your application today.Every integration challenge is unique. We customize tilt angles, sensor alignments, and algorithmic optimizations so customers can move from concept to production faster—with confidence in long‑term performance.

Compact, flexible, all‑in‑one Scheimpflug imaging solution

Our compact, all‑in‑one Scheimpflug imaging solution integrates advanced mechanical designs, intelligent firmware, and FPGA‑accelerated processing into a single platform, simplifying the adoption of Scheimpflug imaging for inspecting objects with 3D structural features.

Key benefits include:

3–10× depth of field extension and an 80% improvement in contrast uniformity, enabling clear, reliable imaging of complex 3D structures.

Processing speed boost through FPGA acceleration while performing distortion correction for high‑precision results.

Compact, customizable form factor, reducing overall system size by 30–50% and ensuring fast, seamless integration into space‑constrained production environments.