SWIR Camera–Based Multispectral Analysis for Salt Monitoring in Food Production

Achieving consistent salt levels in salted vegetables is essential for proper fermentation that affects the flavor, texture, and product reliability. SWIR imaging technology provides new opportunities in revealing subtle variations in salt concentration.

The challenge: Uneven salt distribution is difficult to detect visually

Food manufacturers cannot visually assess salt content or fermentation progress in salted vegetables through surface color or appearance alone. Traditional lab analysis for key components proves destructive, slow, labor-intensive, and chemical-heavy. Multispectral imaging captures full spectral signatures non-destructively, enabling inline salting process monitoring and real-time adjustments to storage/distribution for uniform quality, but drawbacks include elevated system costs and excess spectral data requiring processing. For many food inspection tasks, this level of complexity is not necessary. As such, a targeted SWIR approach provides sufficient spectral contrast for salt detection, enabling a simpler and more economical solution that is better suited for inline quality control environments.

Why SWIR makes salt visible on cabbage leaves

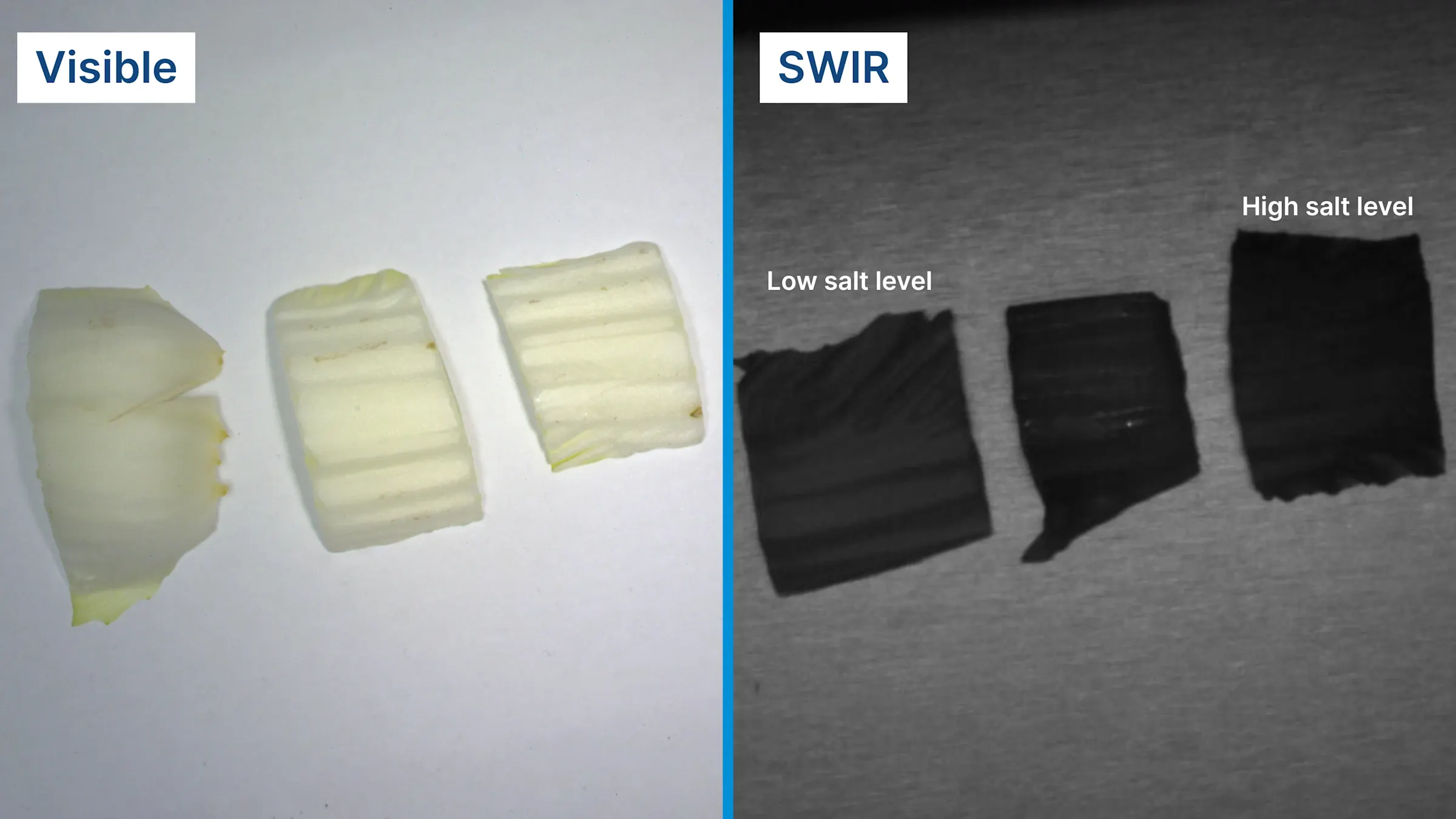

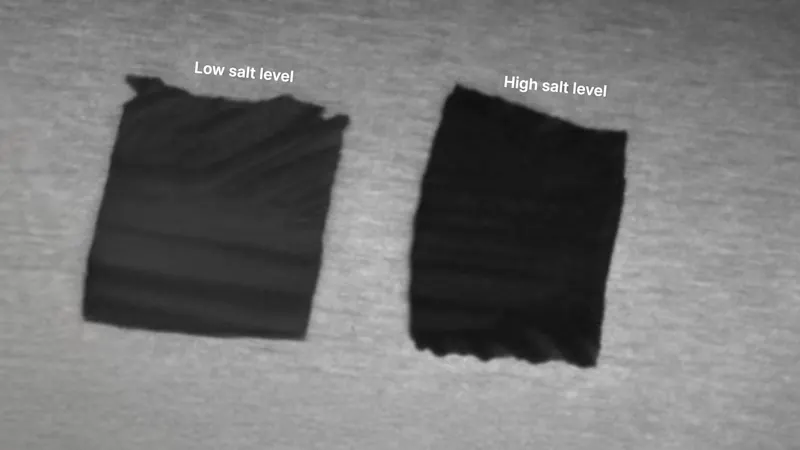

To support consistent fermentation, it’s crucial to monitor how evenly salt interacts with moisture on vegetable surfaces. SWIR imaging makes salt visible by capturing how salt influences the way moisture on the cabbage leaves absorbs and reflects infrared light. When salt is present, it changes the behavior of the thin water layer on the leaf surface, creating measurable contrast in the SWIR range that does not appear in standard visible images. Using SWIR filters or dedicated SWIR illumination further enhances this effect by isolating the wavelengths where these differences are most pronounced. As a result, areas with different salt levels can be distinguished more clearly, even when the leaves look visually similar.

Revealing salt distribution with SWIR imaging

Short-wave infrared imaging makes salt distribution visible in ways that conventional vision systems cannot. In the SWIR spectrum, varying salt concentrations alter moisture absorption characteristics of the vegetable surface, creating measurable contrast relative to unsalted regions. This spectral separation enables reliable differentiation between areas of sufficient and insufficient salting that would otherwise appear uniform under visible light.

Through SWIR-based inspection, food processors can move quality control directly into the production line. The technology supports objective, repeatable evaluation of salt distribution at full processing speed, reducing reliance on manual checks and minimizing batch-to-batch variability.

Food producers are increasingly turning to SWIR because it reveals material properties that visible-light cameras simply can’t capture. As inline quality control becomes more important, SWIR imaging offers a practical way to improve consistency in processes like salting, curing, and seasoning.

SWIR imaging applications for salt level inspection in food processing

The same SWIR imaging principles used to assess salt distribution in vegetables can be applied to multiple stages of food processing where salinity directly influences product quality.

ace 2 X visSWIR camera models

Find the right camera for your application or use our Vision System Configurator to configure your system.