Quality Assurance when Calendering Electrodes

Machine vision systems ensure precise monitoring and reliable fault detection

During calendering, copper or aluminum foils coated on both sides are precisely compacted. Machine vision technology ensures quality and efficiency: the process is monitored in real time, errors are detected at an early stage, and material waste is reduced.

Errors during calendering risk the quality of the electrode coating

Calendering has a significant influence on the uniformity, thickness, and adhesion of the coating. A fine, even layer compensates for fits, ensures stable printing conditions, and minimizes stresses in later production steps.

Critical process step: Calendering as the key to layer quality

Defective coatings within the battery cells lead to unforeseen resistances, poor adhesion, and irregular material distribution. Such defects impair the entire production process and have a major impact on product quality.

During calendering, the coatings on both sides of the copper or aluminum foils are compacted into a homogeneous layer. The process begins with the static discharge of the electrode foil to prevent particle accumulation. Brushes or air streams then clean the foil surface to remove dust and residue. Two counter-rotating rollers - the top roller and bottom roller - exert a defined line pressure on the material. They press the coating together evenly, whereby the material thickness setting largely determines the quality of the compaction.

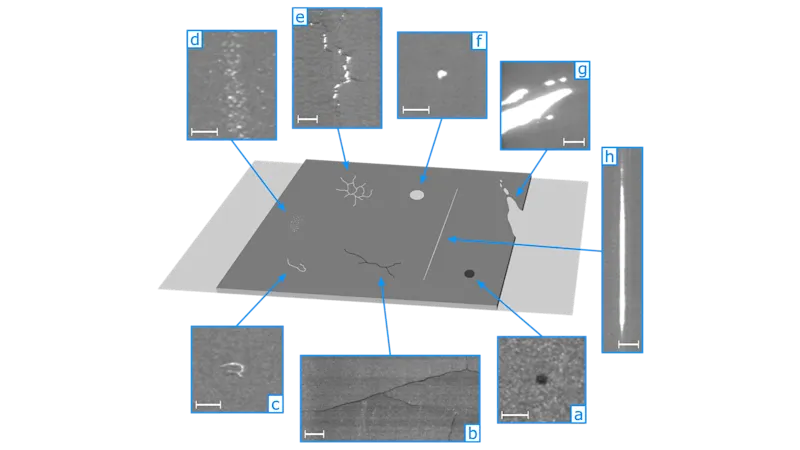

Possible defects in the electrode coating

Errors can occur with both intermittent and continuous electrode coating.

Typical defects are

Agglomerate

Coating crack

Contamination

Micropressing

Mud crack

Blowhole (cavity)

Outbreak or

Striping

Machine vision used during calendering

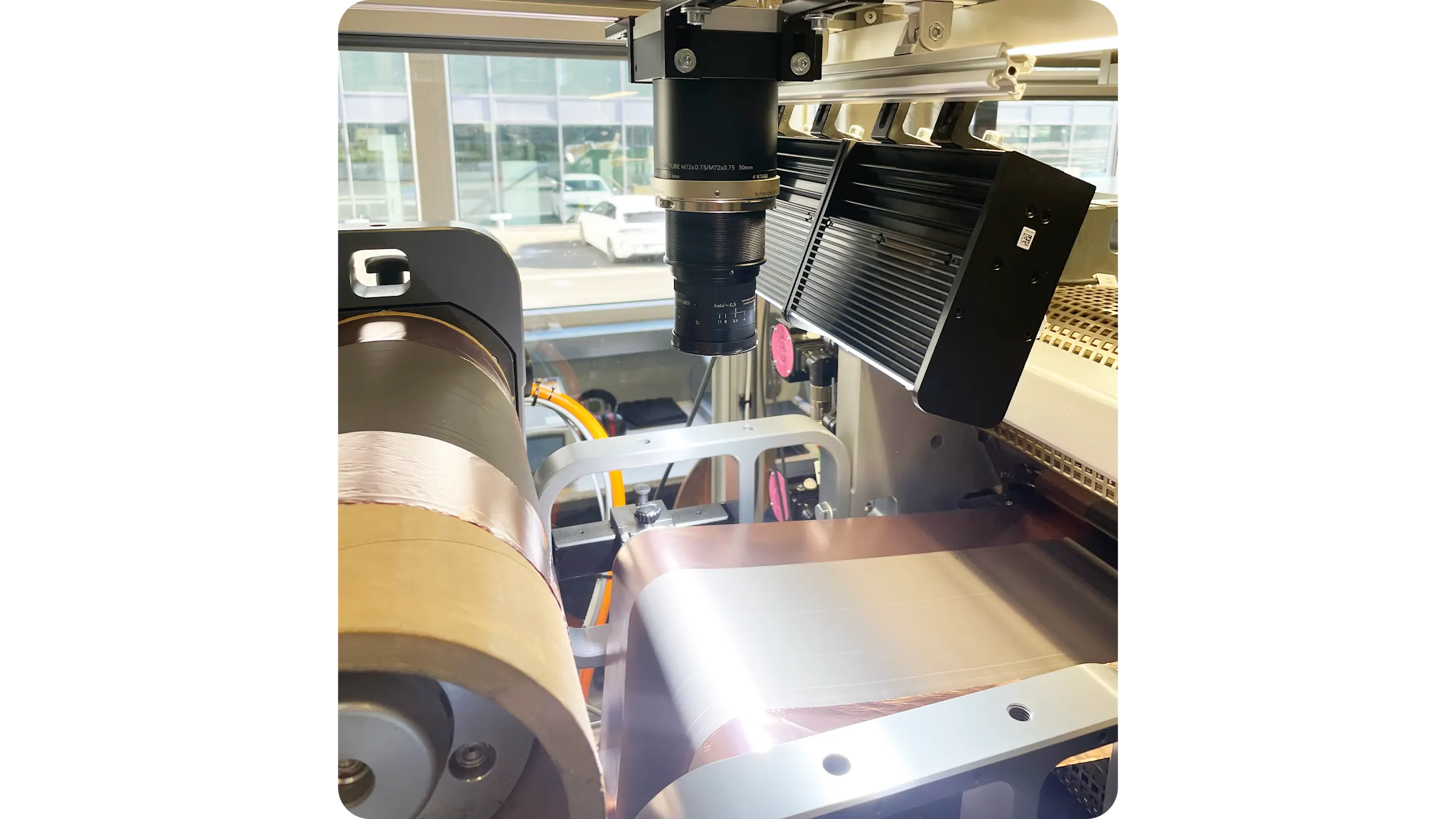

Image processing technology optimizes quality control during calendering by providing fast, documented measurements of film quality.

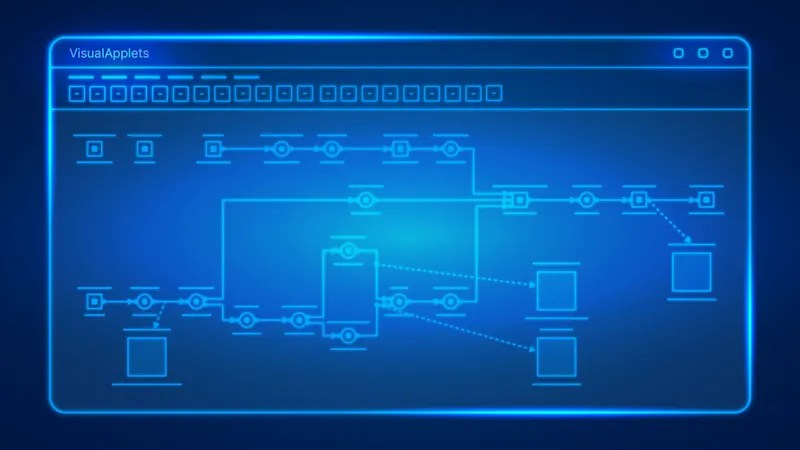

Efficient CPU relief through image pre-processing

The racer 2 line scan cameras allow the process to be monitored at full production speed. The resulting high volumes of data are pre-processed with VisualApplets on a frame grabbeduring the calendering process. By determining the ROI (region of interest), the analysis is limited to relevant band ranges. Only conspicuous sections are analyzed further - this reduces the CPU load and frees up resources for the actual process control.

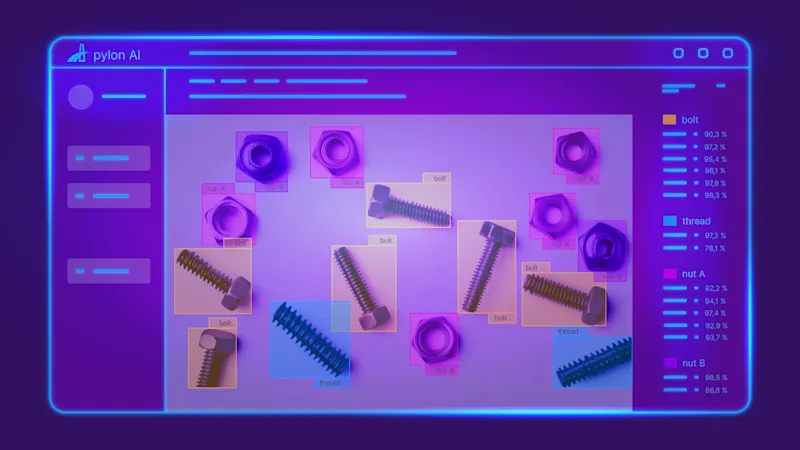

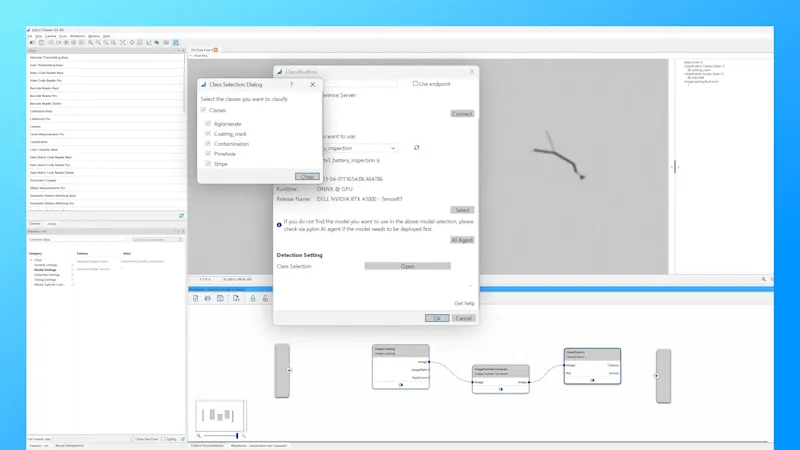

Detect and react to defects with pylon vTools

In the next step, irregularities detected during the calendering process can be analyzed in detail within the ROI. pylon vTools with classic image processing algorithms classify the type of defect (e.g. cracks, material detachment, or surface irregularities). pylon AI enables AI-based analyses to precisely measure the size and extent of the defects.

Depending on the type and size of the defect, a decision is made as to whether the material is still within the specified tolerances or whether further measures are required. Precise defect localization after calendering improves electrode quality and reduces rejects.

Machine vision ensures quality in calendering

High-resolution line scan cameras detect scratches, bubbles, discolorations, particles, or matting on the film surface in real time.

pylon AI vTools take over the automated image analysis, as well as the segmented defect classification (sorting by by size, shape, and position) and the detection of recurring defect images.

Microwave sensors in combination with machine vision enable continuous thickness measurement from coarse to fine resolution across the entire width of the film - from initial detection to sub-micrometer precision measurement.

Using robust image analysis, the system reliably detects deflections and flatness deviations along the film width

About the Chair of Production Engineering of E-Mobility Components at RWTH Aachen University

The Chair of Production Engineering of E-Mobility Components (PEM) at RWTH Aachen University has been researching lithium-ion battery production for many years. The central element of this research group is a pilot line for the production of battery cells that covers the entire process chain. Here, researchers work closely with industrial partners such as Basler to continuously improve individual steps in the production process.

Through its participation in numerous national and international industrial projects in companies at all stages of the value chain, and thanks to key positions in renowned research projects, the PEM at RWTH offers extensive expertise.

Products for this solution

Looking to implement a comparable solution? These products will help you.