Precision Alignment for Bare Board PCB AOI

Enabling accurate trace width measurement with Basler ace 2 camera

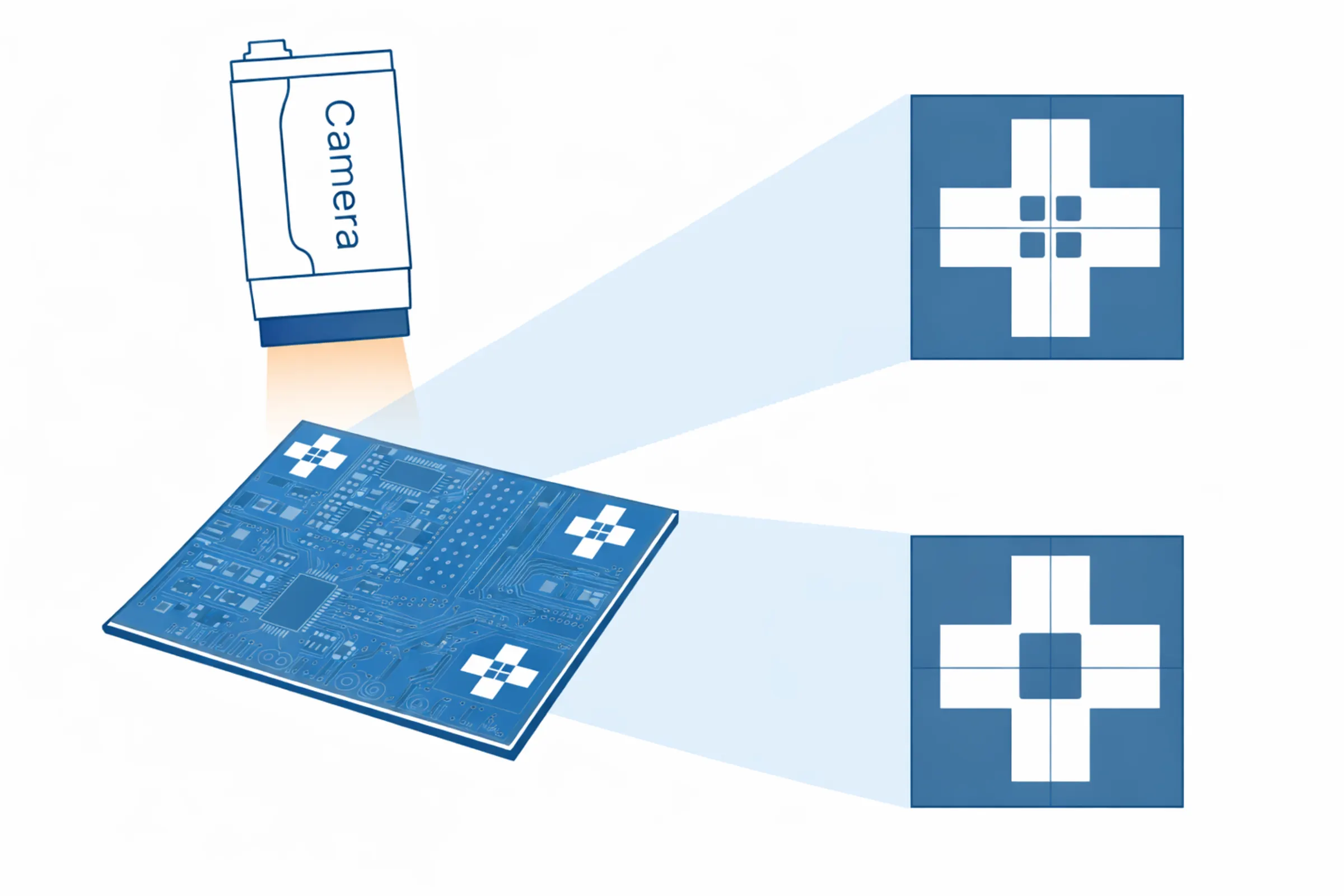

In bare board PCB inspection, trace width measurement is a critical quality control step for ensuring signal integrity and manufacturing consistency. Before trace width can be accurately evaluated, the inspection system must first establish precise and repeatable alignment of the PCB. This alignment is typically based on fiducial marks and serves as the foundation for all subsequent inspection tasks.

Why is precision alignment so critical for PCB AOI?

As PCB designs continue to evolve toward higher density and finer features, alignment accuracy becomes increasingly important. Even sub-pixel misalignment at this stage can propagate into false trace width violations, affecting yield and increasing rework rates.

PCB alignment

High-speed lines use two area scan cameras focused on fiducial marks at opposite PCB corners to correct X-Y position shifts and rotation, ensuring the board is properly positioned for line scan inspection.

Standard alignment process:

Image acquisition: Rapidly capture images of dedicated fiducial marks on the PCB.

Coordinate calculation: Precisely determine the centers of the fiducial marks to establish a reliable reference point.

Platform adjustment: Fine-tune the platform to align the PCB perfectly with the inspection path.

For high-output production lines, this process requires not only extreme precision but also stable image capture over extended periods of continuous operation.

How Basler helps ensure stable alignment in high-volume production

For high-volume PCB manufacturers, the real challenge is not achieving peak performance in a lab environment, but maintaining consistent accuracy in continuous production 24/7.

To achieve consistent alignment performance in high-volume PCB AOI, Basler applies a system-level approach that combines stable imaging, robust camera design, and long-term product availability.

Consistent imaging for reliable fiducial detection

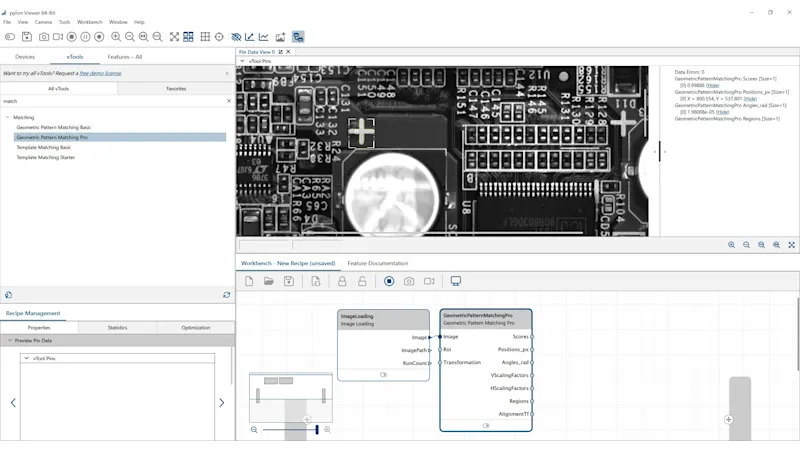

Under high magnification and coaxial lighting, the ace 2 delivers sharp, high-contrast images of fiducial marks, providing precise and repeatable pixel data for alignment algorithms and reducing false calls in trace width inspection.

Long-term stability for continuous operation

In mass production, alignment accuracy must remain stable over time. Basler’s camera platform strategy focuses on consistent imaging performance across product lifecycles, minimizing alignment drift and recalibration effort.

Compact integration and long-term supply

The compact ace 2 design enables easy integration into space-constrained PCB inspection machines. Standardized interfaces and a stable supply roadmap help ensure long-term system support and production continuity.

Validate alignment stability for your high-volume PCB AOI lineBasler ace 2 cameras have proven their consistency and reliability in customer manufacturing environments. Combined with stable cables, intuitive pylon software, and clear lifecycle planning, they form a dependable vision solution for high-volume PCB inspection.

Stable alignment performance backed by long-term reliability

Basler ace 2 enables reliable PCB alignment in mass production by delivering stable imaging performance within a compact, production-ready camera platform. Its design philosophy prioritizes:

consistency over time

predictable product availability

low integration risk

These are key factors for AOI systems that must remain qualified across long production lifecycles.

By minimizing performance drift and component change risk, Basler helps system makers maintain inspection stability, reduce requalification effort, and support continuous high-volume operation with confidence.

Products for this solution

Looking to implement a comparable solution? These products will help you.