Goods Logistics with the TORU Picking Robot and the Basler ace Camera

- Customer

- Magazino GmbH

- Location

- Munich

- Date

- 2015

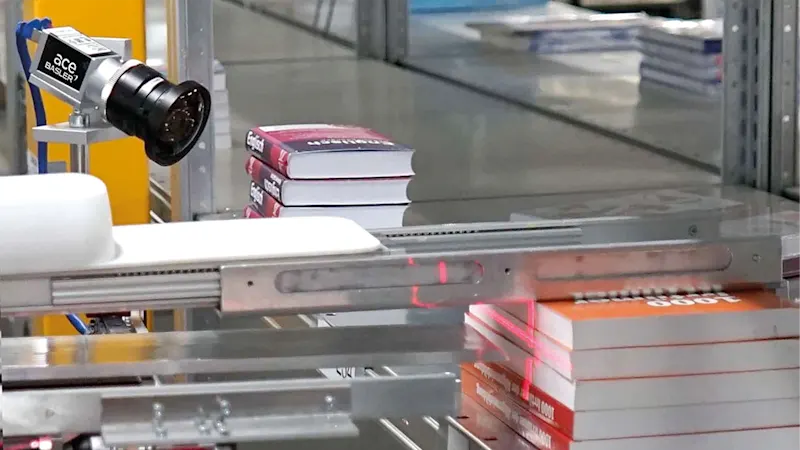

The Basler ace camera is a seeing eye for Magazino's intelligent and flexible picking robot TORU. Combined with a cross laser (sheet-of-light method), it enables the robot to locate, measure and grasp objects on shelves.

Use case

From e-commerce to intralogistics in the automotive industry: individual products are needed in all of these areas nowadays and, more rarely, entire pallets. Until now, humans have almost always had to gather the individual objects from the respective warehouses because robots were unable to do so. The gripping process is considered one of the most challenging tasks in robotics. TORU enables the precise measurement and recognition of objects using the Basler ace camera as well as a secure grip on the individual product.

Solution with Basler ace camera

TORU is a mobile robot that can pick orders in warehouses alongside humans. A merchandise management system sends the picking orders to TORU via WLAN, which then moves independently to the relevant storage location. After successful detection using the sheet-of-light method, TORU picks the object and automatically takes it to the desired destination.

Optimal measurement with the sheet-of-light method

In the sheet-of-light method, a cross laser projects two perpendicular laser lines onto the object to be measured. A 2D camera thatBasler ace acA1920-40gmThe laser scanner picks up the reflected laser beams and measures the object based on the position of the lines in the camera image. This process is optimized for cuboid objects such as parcels or shoe boxes. It can also be used to precisely measure books with curved spines.

The quality of the cameras and the implementation of the pylon software interface is very high. Since every support request is answered in the shortest possible time and with well thought-out solutions, we have found a partner we can rely on in Basler AG.

The advantages at a glance

Lower computing power: In contrast to 3D cameras, the sheet-of-light method with the 2D camera generates fewer 3D points and therefore requires less computing power. This means that the algorithm behind the sheet-of-light method can also be run on a mini-computer, for example.

High flexibility of the picking robot

Reduction of process costs possible

Enables operating time to be extended: it can work in parallel with humans and be integrated into the warehouse during ongoing operations.

Adaptability: Thanks to new concepts and high-quality sensor technology, the robot is able to adapt to new situations and changes in the warehouse.

Products used

Get this solution or a customized machine vision solution from us!

Our experts are happy to advise you on your individual vision project.

Magazino - A Jungheinrich Company

Magazino GmbH develops and builds intelligent robots for precise logistics in Industry 4.0. The Munich-based company has set itself the goal of developing new logistics concepts based on autonomous robots. The special feature: Magazino's robots can react to a changing environment - this is only possible thanks to powerful sensor technology, such as a camera.