Optical Weld Seam Inspection

IUNA AI Systems develops the first ISO-compliant inspection system with machine vision

- Customer

- IUNA AI Systems

- Location

- Untergruppenbach, Germany

- Date

- 2025

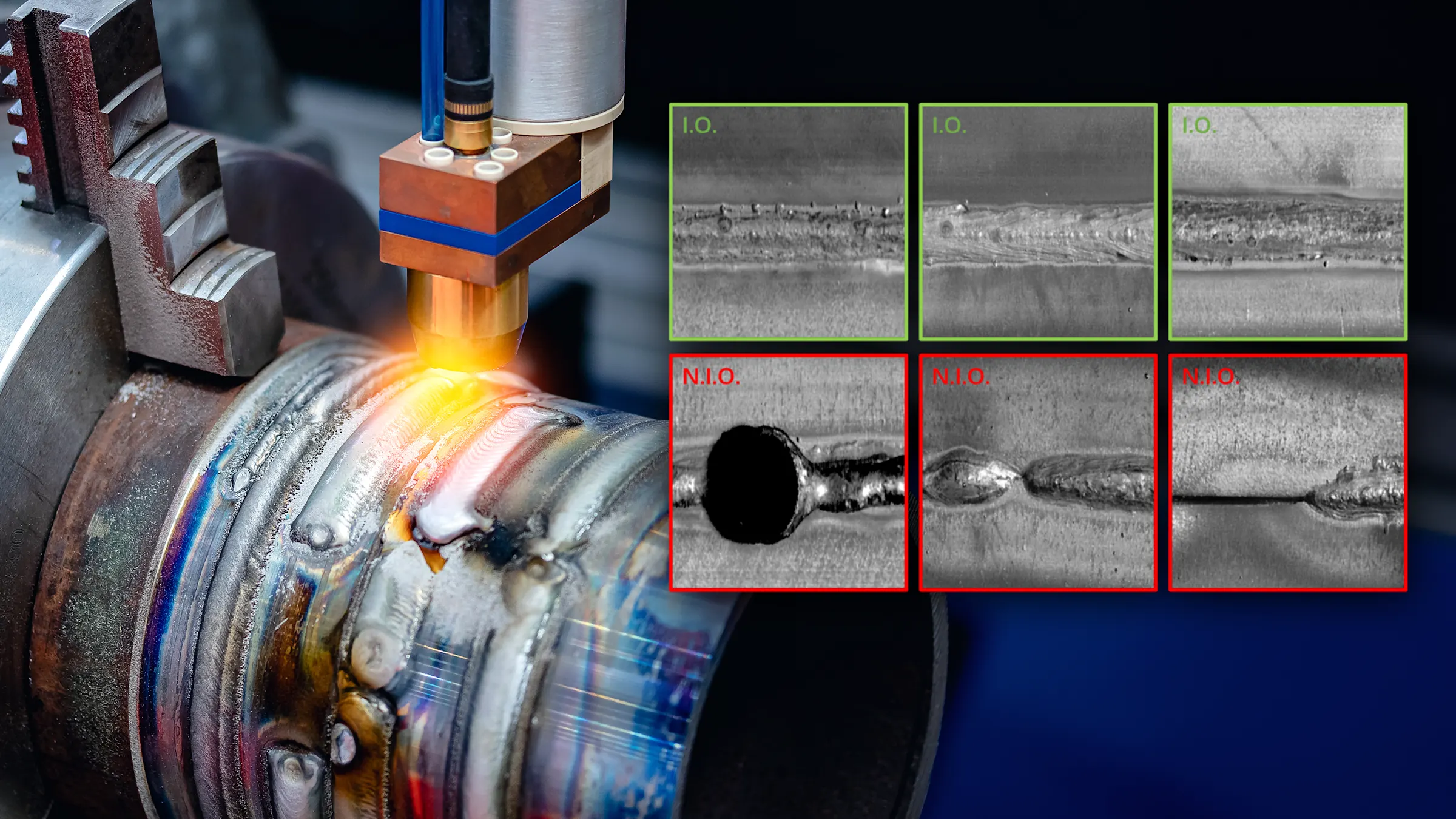

IUNA AI Systems develops AI-based inspection systems with machine vision. Up to 200 networked Basler ace 2 cameras inspect weld seams, synchronously controlled via the pylon software - for complete coverage, high cycle times, and inspection results certified to industry standards. An effective and cost-efficient alternative to conventional methods, such as laser technology, ultrasound, X-ray analysis, and manual visual inspection.

Cheaper, more flexible, and harmless thanks to machine vision

Previously used technologies (such as laser technology, ultrasound, X-ray analysis, and manual visual inspection) are complex to implement. X-ray analysis and laser technology require protective mechanisms for employees, while ultrasound inspection requires clean environmental conditions and is maintenance-intensive. Machine vision simplifies the inspection considerably and therefore saves costs.

Cheaper

Lean system compared to other technologiesMore flexible

Robust AI algorithms ensure process flexibilitySafe & secure

No danger from X-rays or lasersLess maintenance

Less calibration required compared to other methods

IUNA AI offers the first ISO-compliant optomechanical system for weld seam inspection

Rethinking established processes: IUNA AI has set itself the goal of rethinking automation with AI. Their new process for weld seam inspection is already being used successfully in the automotive industry.

Reliability comes standard thanks to precise image data and deep learning

Over 200 Basler ace industrial cameras were integrated in the production line of a German car manufacturer - some on robots, some statically mounted. These cameras inspect weld seams for length, width, pores, cracks, and interruptions. In addition to the seam inspection, the presenceand the exact position of holes, tabs, and rivets are also checked.

The result is automated quality decisions in real time. All inspections are documented in accordance with the applicable ISO standards for weld seams - including images, metadata, and statistics in the user interface. Defective parts are automatically rejected. An analysis dashboard shows quality trends, KPIs, and visual reports in the process monitor.

Standard-compliant with:

✅ Arc welding: ISO 581, ISO 10042

✅ Laser and beam welding: ISO 13919-1, ISO 13919-2

✅ Brazing and soldering: ISO 18279

✅ Defect classification: ISO 6520-1

✅ Test methods: ISO 17637

With Basler at our side, we are taking quality control automation to a new level - faster, more cost-efficient, and more flexible than ever before.

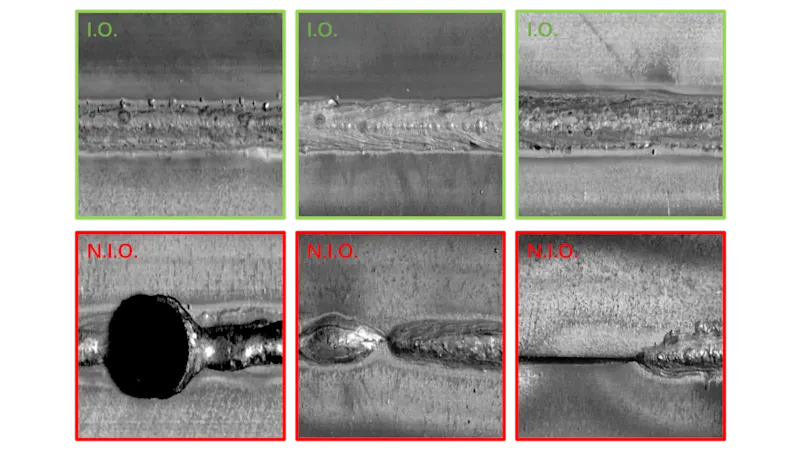

Machine vision for precise I.O./N.I.O. decisions

The AI-supported inspection system from IUNA AIcombines deep learning models with rule-based algorithms. This allows weld seams to be automatically detected, classified, and measured with millimetre precision.

Cracks, pores, burn-through, spatter, asymmetries, and geometric deviations are reliably detected and assessed as I.O. or N.I.O..

The integrated tolerance and segmentation analysis checks the position and dimensions of the seam against defined limit values and precisely delimits faulty areas.

More precise and reliable than manual quality control

Fewer pseudo errors than laser triangulation-based systems

Real-time analysis with immediate feedback to production

An AI is only as good as its image database

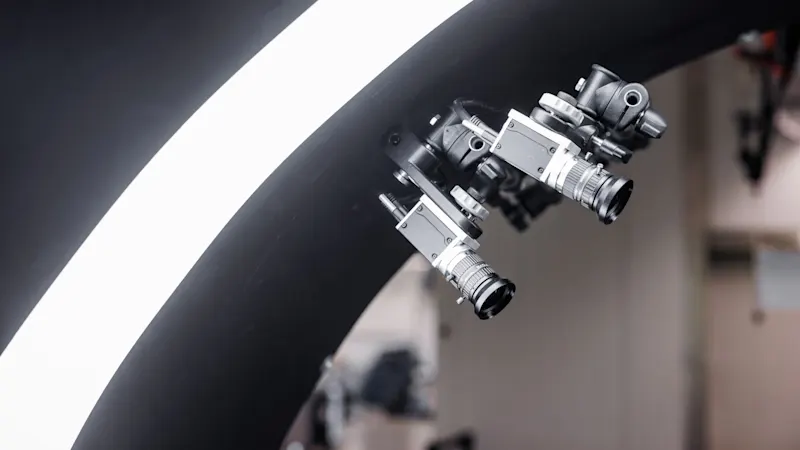

With 200 perfectly timed and synchronized Basler ace 2 industrial cameras, we have helped implement this complex quality assurance system. After all, sharp, detailed image data is the basis for reliable AI analyses to enable certifiable and reliable test results.

ace 2: Precise recording of fine details in production processes

The following machine vision components from Basler were used for this solution:

High image quality and reliability at a good price-performance ratio: the model a2A3840-13gcBAS with the IMX334 sensor offers a resolution of 3840 x 2748 pixels: This enables the precise capture of fine details on weld seams and components.

The cameras are equipped with C23-5M lenses (C-mount thread). Depending on the working distance of the camera-lens combination, focal lengths of 8, 12, 16, 20, 25, 35 and 50 mm are used.

The GigE interface ensures reliable and fast data transmission, while the compact design facilitates integration in confined environments.

discover the ace 2 seriesMulti-camera system and software integration with pylon SDK

The Basler pylon SDK controls the collaboration of over 200 ace 2 GigE cameras centrally and precisely. Thanks to Precision Time Protocol (PTP), an integrated system with exact synchronization and real-time capability is created. The precisely developed pylon SDK displays its full strength in demanding applications and stands for high stability and performance for uninterrupted image processing.

Through integration into the AI-supported software platform from IUNA AI, images are analyzed using state-of-the-art deep learning algorithms. The open API makes it easy to adapt camera parameters. This allows the systems to react flexibly to new production conditions or product variants at any time.

Our developers get on well with the pylon software. If we had any questions, the technical support was regularly available at short notice and was able to help us.

Products for this solution

Looking to implement a comparable solution? These products will help you.

About IUNA AI

IUNA AI Systems GmbH was founded in 2020 and is based in Untergruppenbach near Heilbronn, Germany. The company develops deep learning-based camera systems and image processing software for the automation of quality assurance in industrial production. IUNA AI Systems combines expertise in the fields of software development, machine learning, and automotive manufacturing. This results in state-of-the-art AI vision systems that solve real-world quality control challenges.