HDR Imaging and Tone Mapping for Reliable Defect Detection in Harsh Lighting

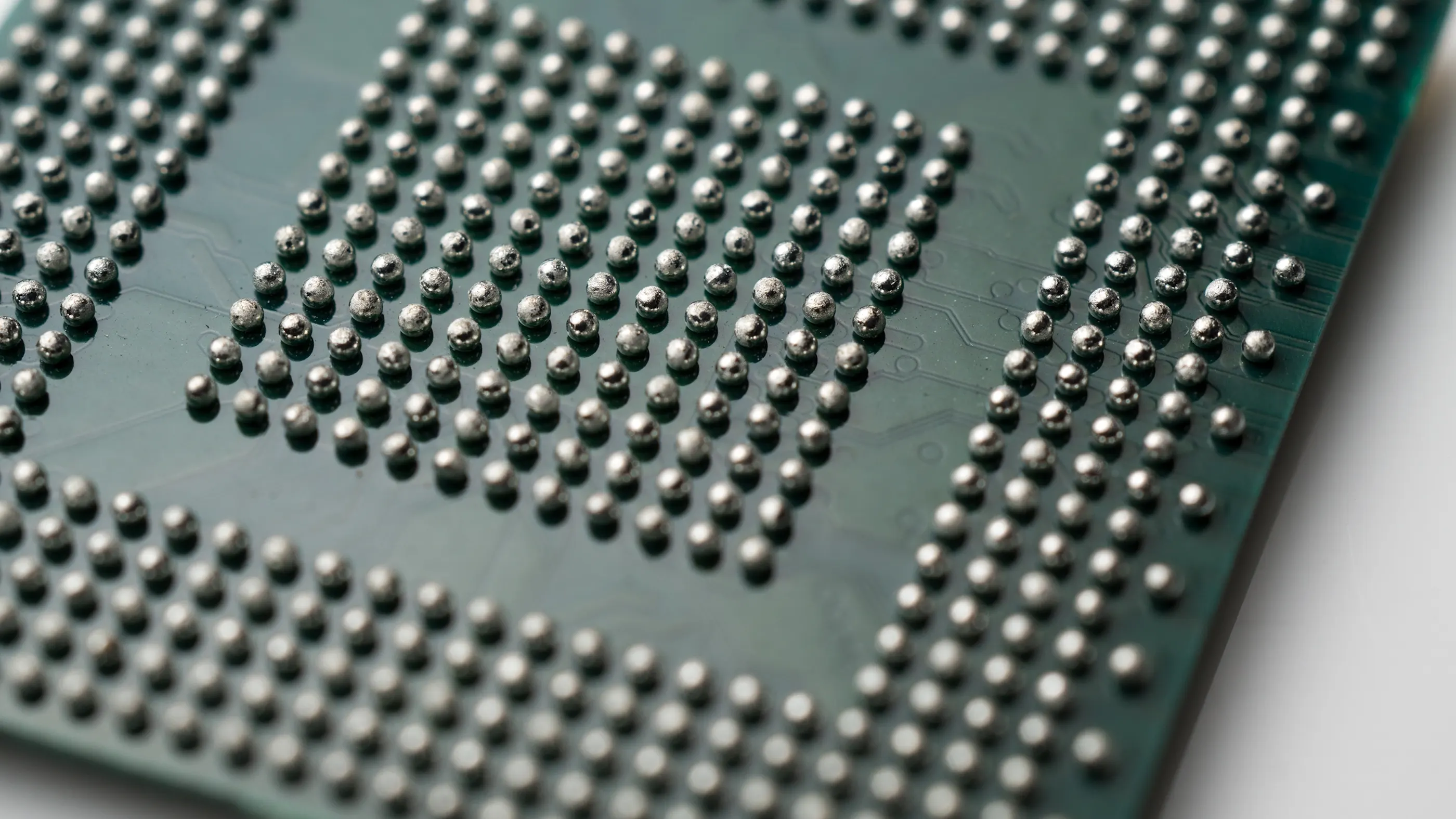

Industrial and electronics manufacturing often involve high-contrast scenes with bright reflective surfaces adjacent to dark recessed areas. Standard imaging systems struggle to capture complete details across these extreme lighting conditions, particularly under throughput constraints. Basler offers a portfolio of HDR-capable solutions tailored for motion, contrast, and throughput demands. This use case demonstrates how the IMX676-based DOL HDR option works in practice.

Reliable inspection across reflective, transparent, and shadowed surfaces

Many low-contrast, micro-scale defect detection applications frequently encounter extreme contrast scenarios that present significant imaging challenges. Some typical application scenarios include:

In these challenging scenarios, even optimal lighting design cannot fully resolve the fundamental optical conflict between the need to properly expose bright reflective regions (without overexposing them) and simultaneously capture sufficient detail in darker areas (without underexposing them).

Standard imaging approaches struggle to simultaneously capture critical details across the full dynamic range of these high-contrast scenes. This limitation often results in the loss of essential information in either highlights or shadows, which can significantly compromise defect detection accuracy and reliability in precision inspection applications.

Example application: IMX676-based HDR with Basler’s in-camera tone mapping

The Basler ace 2, equipped with Sony’s IMX676 sensor, delivers over 90 dB of dynamic range using DOL HDR. With tone mapping implemented in the camera, it provides balanced images directly—no host-side processing required. Output formats include Bayer8, Bayer16, RGB8, and YCbCr for both display and algorithmic use.

Harness DOL HDR for seamless highlight-shadow capture

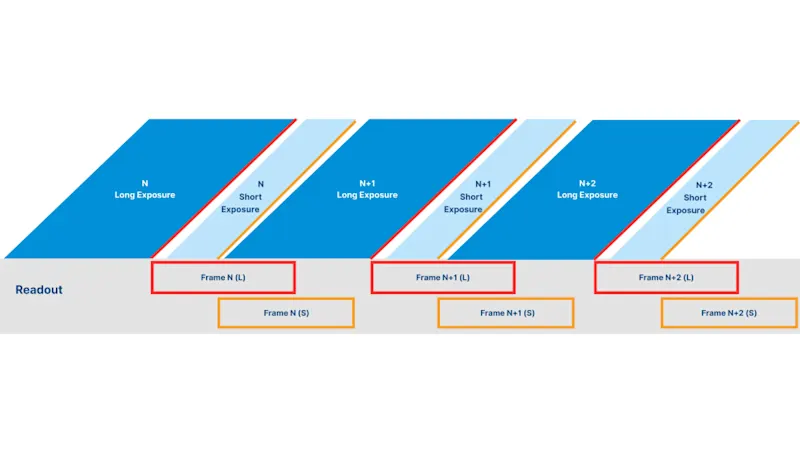

Digital Overlap (DOL) HDR is designed for rolling shutter sensors, where lines are exposed sequentially. Instead of waiting for the entire frame to finish, DOL HDR starts the next exposure while the first is still in progress. This overlap enables HDR within a single frame period without multiple full-frame captures.

Basler integrates DOL HDR directly into the ace 2 IMX676 camera through firmware-level optimization and built-in tone mapping. This implementation delivers high-dynamic-range output ready for immediate visualization or processing, eliminating the need for external synchronization, complex exposure timing, or host-side image merging.

The result: seamless highlight-shadow capture within one frame, ideal for detecting defects like microcracks, scratches, or contamination - even in scenes with high reflectivity or deep contrast.

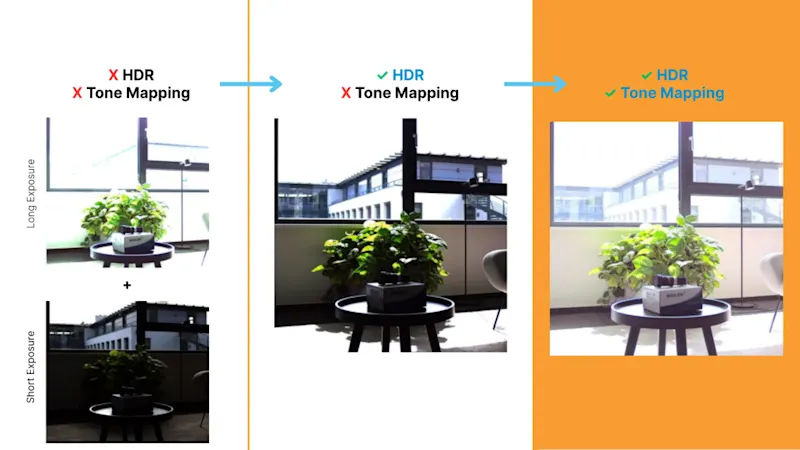

From raw data to display: The role of tone mapping

HDR sensors like the IMX676 can output high-bit-depth data (e.g., 16-bit Bayer), which preserves the full dynamic range across shadow and highlight regions. Tone mapping compresses this dynamic range non-linearly into 8-bit formats (e.g., Bayer8, RGB, YCbCr) for display on standard monitors.

In the ace2 IMX676, tone mapping is integrated directly into the camera firmware. This allows real-time, natural-looking images without extra host-side processing, especially useful when images are meant for human operators.

However, for machine vision applications where images are processed algorithmically, tone mapping is optional. Algorithms can work directly on the raw high-bit-depth data, retaining full dynamic range and precision.

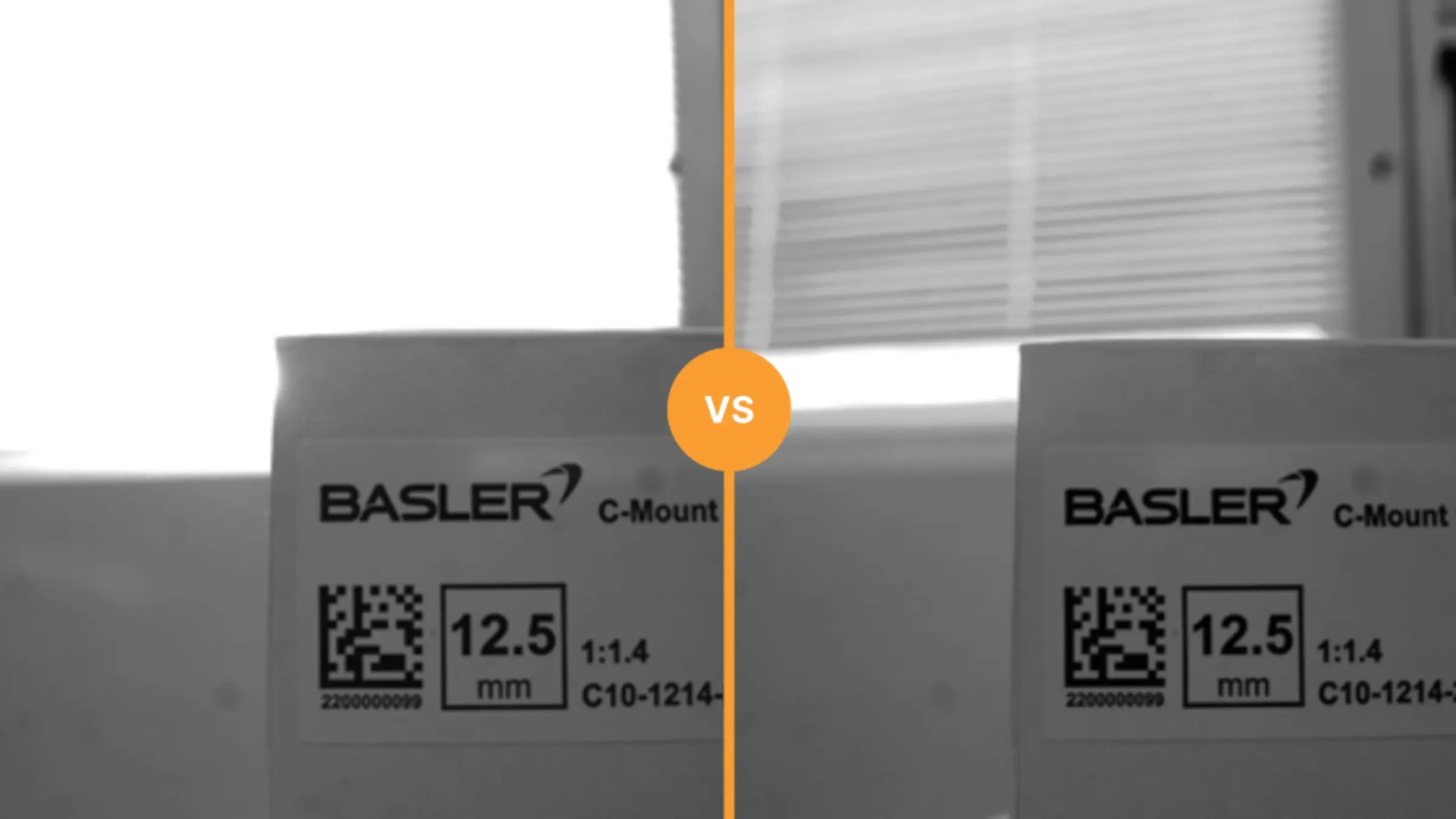

In-camera DOL-HDR and tone mapping vs. Software solution

In-camera DOL-HDR with tone mapping offers significant advantages over software-based HDR approaches like OpenCV. Since exposures are overlapped, the temporal gap between long and short exposures is significantly reduced, something software processing can't match. This results in faster, cleaner HDR output, especially for live and motion-sensitive applications. The table below highlights the key differences:

Feature | ace 2 IMX676 with DOL-HDR + Tone Mapping | Software-Based HDR (e.g., OpenCV) |

Processing Speed | Real-time in-camera | Slow, requires CPU/GPU processing |

|---|---|---|

Latency | Very low | High |

Motion Artifacts | Minimized | Higher risk of ghosting |

Bandwidth Efficiency | Single optimized image output | Multiple image transfers |

Use Case Suitability | Industrial vision | Photography; Post-processing scenarios |

Comparing HDR methods: Choosing the right one for your application

While the IMX676 with DOL HDR and tone mapping is ideal for many mainstream use cases, Basler supports several HDR methods, each tailored for specific needs.

HDR Methods | Technique | FPS Impact | Motion Robustness | Resolution | Image Quality (SNR) | Dynamic Range2 |

|---|---|---|---|---|---|---|

Multiple image captures with different exposure times | ||||||

Multi-Exposure | Multiple (N) frames, combination and tone mapping done on the host system | 1/N | Poor | Full | ♦♦♦ | +(N-1) x ■■ |

DOL HDR1 (e.g. IMX 676) | Two exposures with in-camera-processing (combination and tone mapping) | Moderate | Moderate | Full | ♦♦♦ | +■■⧠⧠ |

Quad HDR1(e.g. IMX900) | Multiple exposure times in a single scene using per-pixel control | None | Good | 1/4 | ♦♦♦♦ | +■■■■ |

Interleaved HDR (e.g GMAX sensors) | Two different exposure times line by line within a single image capture | None | Good | 1/2 | ♦♦♦ | +■■⧠⧠ |

One image capture, multiple gains | ||||||

Dual Gain | Single Exposure, reading the same pixel with two different gains | 1/2 to moderate depending on sensor | Good | Full | ♦ | +◪⧠⧠⧠ |

Dual Conversion Gain (DCG)1 (e.g. IMX53X series) | Single Exposure, reading the same pixel with two different gains | None | Good | Full | ♦ | +◪⧠⧠⧠ |

Clear HDR1 (e.g. IMX676) | Single Exposure, reading the same pixel with two different gains | None | Good | Full | ♦ | +◪⧠⧠⧠ |

One image capture, other techniques | ||||||

Binning Fusion | Combining adjacent pixels (N) within one frame | None | Good | 1/N | ♦♦♦ | +◪⧠⧠⧠ |

IMX490 | Each pixel has two sensitivity areas | None | Excellent | Full | ♦♦♦ | +■■■■ |

Footnote:

1. Feature by Sony

2. Actual dynamic range improvement depends on sensor architecture, scene characteristics, and implementation. Symbols indicate relative capability and do not imply fixed or guaranteed performance.

The key to successful HDR implementation lies in understanding your specific inspection requirements. When customers approach us with challenging lighting scenarios, we evaluate their object movement patterns, throughput needs, and quality requirements to recommend the optimal HDR approach. Our R&D team has developed a range of HDR methods, each tailored for different motion, resolution, and integration needs.

Summary: Why choose Basler HDR imaging?

For high-speed lines or detail-critical inspections, no single HDR method fits all. That’s why Basler offers more flexible HDR solutions to meet different motion and imaging requirements:

Comprehensive options: Includes multi- and single-exposure methods, sensor-level features, and FPGA-based processing.

Integration-friendly: Real-time HDR and in-camera tone mapping reduce host-side processing needs.

Scalable and future-ready: Supports the latest sensor technologies for evolving inspection demands.

Our custom capabilities

Our engineers can help you evaluate which HDR solution fits your inspection needs, whether it’s DOL HDR, Dual ADC, or Quad HDR.

Discuss your project with us