FPGA-Based Real-Time Lighting Control and Signal Processing

Fast and reliable trigger response without CPU load

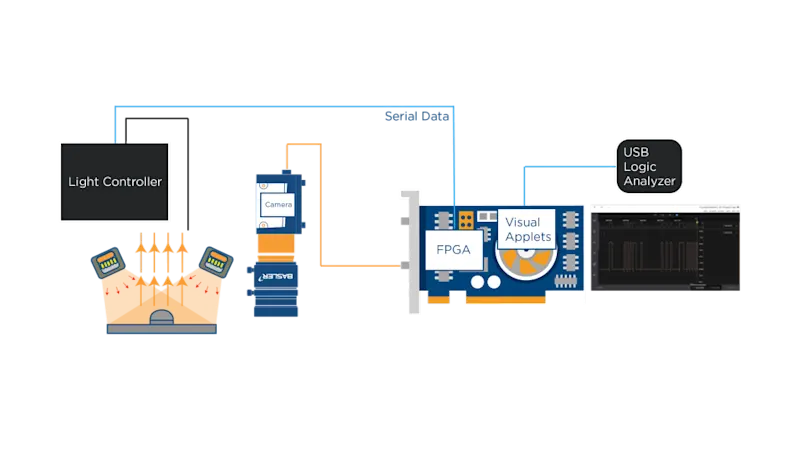

The Basler solution implements real-time control of external lighting controllers directly on the FPGA based on image analysis results, eliminating the need for intervention by the CPU or host PC. Within the VisualApplets environment, the FPGA on the frame grabber calculates the average brightness of the image and automatically controls the lighting according to predefined threshold values.

Why real-time signal control matters

In automated optical inspection (AOI) and other industrial vision applications, real-time signal control—especially for lighting triggers—is critical to inspection accuracy and production efficiency. High-speed defect detection requires microsecond-level synchronization between lighting, cameras, and motion systems.

To achieve this, control systems must process trigger signals instantly without burdening the CPU, maintain consistent timing at production speed, and adapt to different setups. Traditional CPU-based solutions often fall short, as heavy data loads and complex synchronization introduce latency and timing errors that reduce inspection quality.

From CPU bottlenecks to FPGA precision: Solving the latency problem

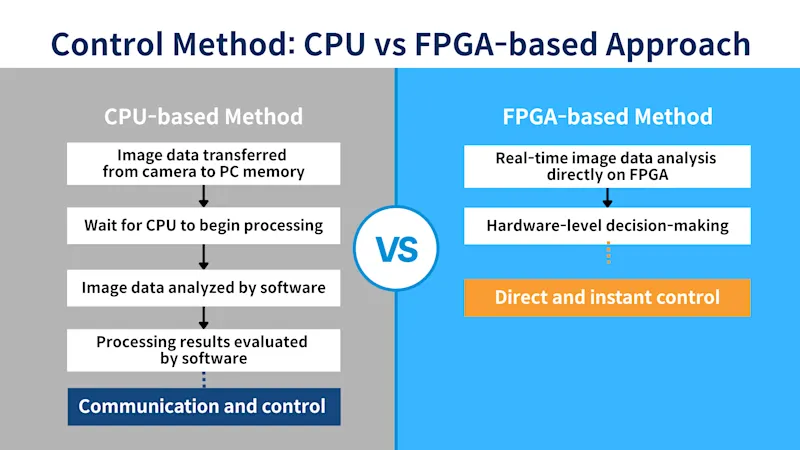

A key challenges in AOI systems is the latency and temporal unpredictability that arise when converting image analysis results into actual control actions.

CPU-based systems handle trigger logic in software, making them vulnerable to delays from OS scheduling and background processes. This makes it difficult to ensure consistent response times and often introduces timing variations that compromise inspection accuracy.

Basler’s FPGA-based approach overcomes these architectural limitations by embedding control logic directly into hardware. Both image analysis and control signal generation are executed on a single hardware pipeline inside the frame grabber, enabling deterministic processing without external interference. Signals are processed instantly, ensuring precise synchronization between camera, lighting, and motion control.

On high-speed production lines, this architecture achieves microsecond-level precision in timing while scaling reliably as system complexity increases. It enables a responsive system in which control actions are executed immediately based on image analysis results — a structural shift from the traditional “inspect-then-decide” model to a true “detect-and-respond in real time” architecture. At the same time, it reduces CPU and GPU load, leaving more resources available for advanced image analysis.

Lighting is just the beginning: Expanding FPGA control to more vision tasks

While the demo focuses on lighting control, the same FPGA-based architecture can be extended to a wide range of real-time signal processing tasks, enabling much more than precise lighting synchronization.

Real-time lighting control demo

The lighting control logic implemented in the Basler solution goes beyond simple ON/OFF operations. By replacing the average brightness calculation algorithm with other image analysis algorithms, it becomes possible to integrate and control various external devices.

In this demo, lighting control signals—based on average brightness analysis of image data—are transmitted directly to the lighting controller via the frame grabber’s General Purpose Output (GPO) using the RS232 protocol. This hardware-level direct pipeline eliminates software overhead, ensuring a rapid and reliable system response.

Request a demo or talk to us about your solution needsExpanding system capabilities

What makes this architecture powerful is its scalability. By simply modifying the control algorithm or output format, the same FPGA-based framework can be extended beyond lighting to control a wide range of external devices. A variety of control scenarios can be implemented flexibly within the same architecture, from device synchronization to advanced signal processing.

In addition to lighting, FPGA-based control can handle on-the-fly image preprocessing—such as filtering, region-of-interest selection, or data reduction—so that only essential data is passed on to the CPU or GPU. The same approach can synchronize multiple devices, align timing on high-speed inspection lines, and support complex I/O control.

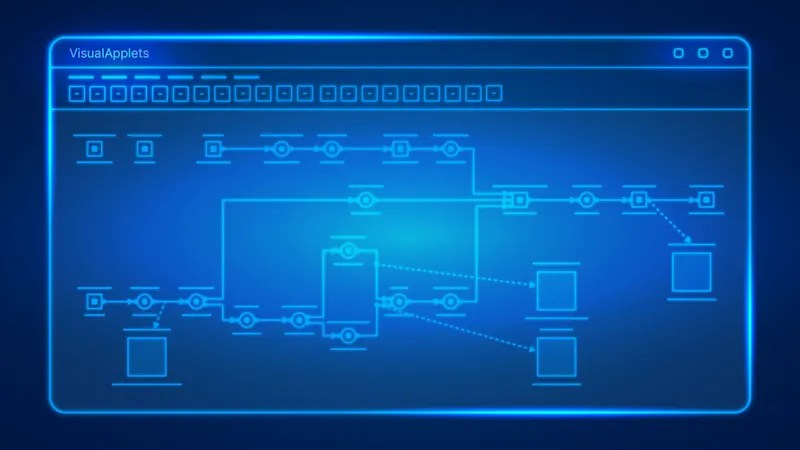

With Basler’s VisualApplets environment, users can easily design and customize this logic through intuitive block diagram programming, without the need for low-level hardware coding. This ensures site-specific adaptability and long-term flexibility in demanding AOI environments.

Example Applications:

High-speed inspection lines: Real-time lighting synchronization with moving products

Multi-product manufacturing: Auto-switching of lighting conditions based on detected product type

Quality-driven adjustment: Dynamic lighting correction based on real-time quality feedback

Complex inspection setups: Sequential or simultaneous control of multiple lighting units

Basler’s FPGA solution excels not only in image-based processing but also in signal processing. It enables the implementation of custom signal processing, allowing for more precise system control through specialized I/O signal handling.

From inspection-centric to control-centric: The evolution of machine vision

Today’s machine vision systems are evolving from simple inspection tools to responsive architectures that integrate real-time control. In this transformation, FPGA-based vision solutions are gaining attention as low-latency hardware platforms capable of high-speed image analysis, deep learning processing, and direct execution of control commands.

Especially in Industry 4.0 environments, sensors, actuators, and machine learning algorithms must work in sync to enable predictive maintenance, adaptive control, and real-time quality optimization — key elements of smart manufacturing.

Supporting products for this solution

Interested in building a similar solution? The following products can help you get started.