Bin Picking for Automated Machine Tending

Reliable object detection for pick-and-place robots

Efficient production relies on automated machine tending. Bin picking, the robot-based picking of randomly positioned parts from a load carrier, is a key technology for this. With a vision solution consisting of a 3D camera and intelligent software, robots reliably detect, localize, and pick components, workpieces, and bulk material. This leads to shorter cycle times and higher productivity.

3D CADMatch module: Safe grasping without collisions in real time

The most difficult hurdles for grasping parts include their variety, a dense and chaotic arrangement in the container, and dark lighting conditions. Parts often overlap and can be dark, entangled, or highly reflective. This makes it difficult for the robot to distinguish between them and identify grasping points.

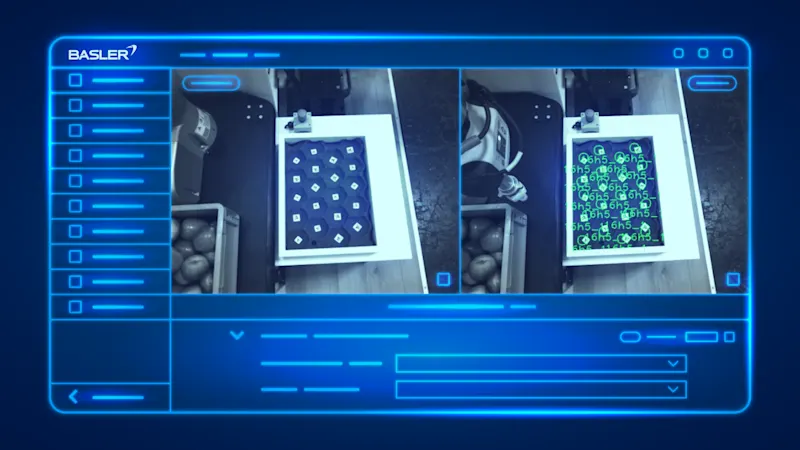

The AI-supported 3D CADMatch module enables precise detection and grasping point calculation based on the camera images and stored CAD data of the respective parts. The software detects strongly overlapping and rotationally symmetrical parts in unmixed load carriers reliably and with short cycle times - regardless of their position or orientation.

Positioning and prioritization of parts

A trained CAD model of the part to be grasped is stored in the 3D CADMatch module. 3D CADMatch compares this CAD model with the 3D point cloud of the container contents, which is generated by the 3D camera. This allows the software to identify individual parts in the point cloud, even if they are overlapping or partially obscured. It calculates the exact position of each individual part along X, Y, and Z coordinates and its orientation in space for successful pick planning. The software prioritizes the most accessible, uncovered parts.

Determining the grasping points for flexible bin picking

The 3D CADMatch module calculates the optimal grasping points (one or more per part) for the robot based on the determined position. It uses information on suitable grasping positions from the CAD model as well as the stored gripper models (two-finger gripper or suction gripper). The software takes into account factors such as the stability of the grip and accessibility for the robot arm and gripper. Another factor is the collision-free nature of the gripper thanks to an optional collision check with the load carrier and, depending on the configuration, other geometries (e.g. point cloud).

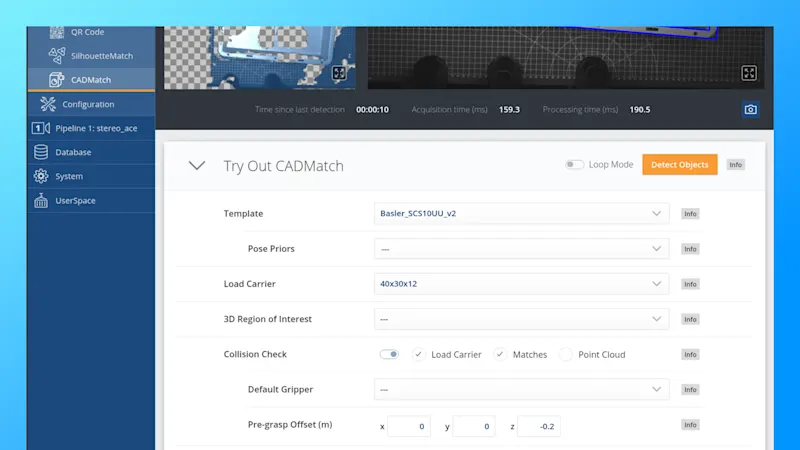

The grasping points are defined once in the CAD template and can be checked in the web interface and adjusted if necessary. During operation, CADMatch automatically supplies the calculated grasping poses to the robot system. The result is a list of prioritized grasping points per part.

Precise planning of the robot track avoids collisions

The optional collision check ensures that the defined gripper does not collide with the container or the surrounding area when approaching the grasping points. This reduces downtime and damage to the system. The software provides the collision-free grasping poses in suitable coordinate formats. The actual path planning and the generation of the movement commands take place in the robot system or in a higher-level controller.

Intuitive parameterization instead of programming

With the web-based user interface, users usually parameterize the software in the following order:

Select the CAD template of the part and check stored grasping points

Configure the load carrier and work area (region of interest)

Optionally activate collision check and select gripper models

Define gripper type (two-finger gripper or suction gripper)

In practice, a new image is often generated after each grasping process. The updated point cloud enables the robot to continue working reliably even if parts have slipped.

Once CAD models have been parameterized, it is much easier to set up new picking tasks for other parts.

3D CADMatch: Everything for bin picking in one software

High precision: Extremely precise grasping of jumbled parts, even if they are complex in shape and lying close together.

Increased productivity: The reliable calculation of grasping points in real time optimizes cycle times and reduces scrap and rework. Preferred grasping directions and different gripper types are taken into account.

Plug and play functionality: Thanks to the browser-based web interface, the software on the Basler stereo cameras can be intuitively parameterized and activated - even by operators without in-depth specialist knowledge. Grasping points can be set and adjusted interactively, which significantly speeds up commissioning.

Easy integration: As part of the modular pylon software, the 3D CADMatch module can be seamlessly integrated into existing robotics applications.

Delivery includes two CAD models as templates. Additional models are set up by us as a service.

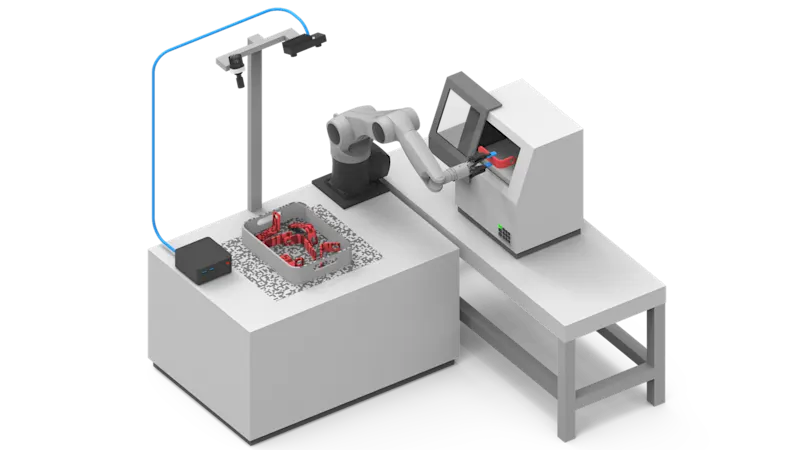

Components of the 3D bin picking robot system

In addition to the 3D CADMatch module, a Basler Stereo visard or Stereo ace 3D camera and matching components form the technological basis of the vision system. The cameras ensure precise depth detection of the recorded scene.

A complete solution for fast cycle times

Compatible hardware components can be quickly configured and integrated into the bin picking application as a complete system:

A Stereo visard camera can be mounted on the robot arm (on-arm) or alternatively a Stereo ace can be mounted statically above the load carrier (off-arm). The pre-installed onboard firmware allows plug and play commissioning.

The 3D Camera Cube is an edge computer that provides the computing power required for 3D CADMatch. It is mandatory for the use of 3D CADMatch and can process up to four stereo cameras simultaneously, depending on the variant.

The optional Randomdot Projector projects a dot pattern onto the surface for additional depth information on smooth surfaces. It is useful if the integrated pattern projector of the Stereo ace is not sufficient or the Stereo visard is used without a projector.

Lighting: Additional light minimizes reflections and highlights deep contours. We offer a large selection of lighting for this purpose.

Easy integration into the robotics application

Integrating the vision solution into the robot controller is essential and a decisive factor for the efficiency and reliability of a robotics application. It can be seamlessly integrated into existing robot cells and is compatible with various robot and gripper systems.

With their ethernet interface, the Basler Stereo visard cameras ensure stable and fast data transmission and enable easy integration into existing systems.

Software interfaces available: Integration modules and sample programs are available for many common robot brands, which can be used to integrate the vision solution into the robot controller.

EKI Bridge for KUKA

URcap for Universal Robots

Generic Robot Interface for ABB, FANUC, and Techman Robot. Franka Robotics, Fruitcore Robotics, and Yaskawa will follow soon. We will be happy to provide them on request.

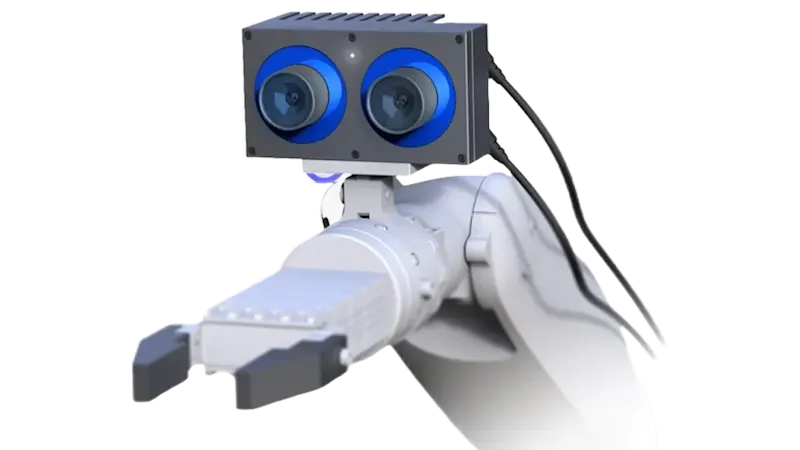

Basler Stereo Cameras: Precision meets quality

Basler Stereo Cameras provide high-quality stereo and depth data for robotics and automation. Depending on the integration concept and scene requirements, two product lines are available: Stereo visard as a smart sensor with on-board processing and pre-installed software, and Stereo ace as a flexibly configurable active stereo camera for host-based processing.

Stereo visard: Smart 3D sensor with on-board software

On-board processing and web interface, designed as a "plug-and-produce" vision sensor without the need for an external vision PC

Standardized interfaces for integration and automation, including REST API, ROS, and GenICam

Variants for different working distances and installation situations, e.g. rc_visard 65 for robot-supported applications and rc_visard 160 for external, stationary, or navigation setups

Optional random dot projector to increase the scene texture on difficult, less structured surfaces

Expandable with optional on-board software modules for typical robotic tasks, including pick-and-place

Stereo ace: Active stereo with integrated projection and high configurability

Integrated projector for active stereo, specifically for scenes with low natural texture

Base distances of 100, 200, and 300 mm, each in mono and color; can thus be adapted to the working distance and measuring range

Host-based processing via Basler Stereo Supplementary Package for pylon and GenTL / GenICam compatibility, including direct support of Aravis

Variants and customer-specific adaptations possible (e.g. other ace 2 GigE models, resolutions, lenses, mounting, and lighting) depending on requirements and quantities

Performance data such as depth FPS are configuration- and host-dependent, suitable if the overall system is specifically designed for performance and image processing

Our vision solution consisting of a 3D camera and intelligent software recognizes objects precisely and calculates safe grasping points in real time. As a result, bin picking remains reliable even under difficult conditions - with short cycle times and maximum system availability.

Products for bin picking with 3D stereo vision cameras and 3D CADMatch module

Would you like to implement a comparable solution? These products can help you.

Get this solution or a customized machine vision solution from us!

Our experts are happy to advise you on your individual vision project.

How does your bin picking application benefit from this solution?

Robust 3D recognition: Reliable part recognition in real time from depth information and CAD matching, even with strong reflections and complex stacking situations, leads to a reduced failure rate.

Increased efficiency: Automating manual activities with fast data processing leads to higher cycle rates.

Scalability: Suitable for a wide range of part shapes as well as container and batch sizes.

No expert knowledge: No AI expertise is required. We train the AI model based on synthetic data from the CAD model of the part supplied.

Time and cost savings: Reusing trained CAD models can reduce development costs and is a cost-effective alternative to classic 3D methods, such as laser triangulation or structured light, in many applications.

Basler Application Software for Robotics

An extensive selection of application-specific 3D software modules provides solutions for typical robotic tasks such as bin picking, machine tending, or order picking. The modules can be easily activated on the Basler stereo cameras and intuitively operated via the sensor's standard interface. Optional hardware add-ons such as projectors or lighting further optimize operation.

Application Software for Robotics