AI-supported picking of consumer goods packaging

Software module for AI-supported object recognition and gripping point determination in order picking

The use of 3D image processing and our ItemPickAI software increases efficiency and precision in warehouse logistics. The software supports the picking process: the AI recognizes consumer goods (e.g. food, drugstore, and electronic items) in densely packed containers and provides precise gripping points for the robot. Benefits: lower error rates and faster order processing.

Precise order picking in confusing environments

Automated picking faces the challenge of gripping a wide variety of objects with precision. ItemPickAI This is exactly where software comes in: It enables robots to recognize a wide range of consumer goods - from food to electronics - even in densely packed containers, and determine optimal gripping positions. This results in lower error ratesandreduced product damagein warehouse logistics.

AI-based gripping point determination

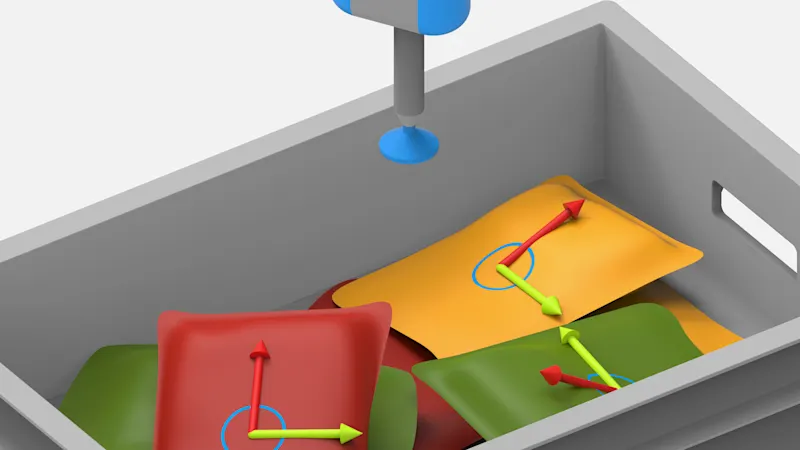

With the new "consumer goods" model type, ItemPickAI optimizes picking. The AI identifies items and calculates the optimal gripping position, regardless of the gripper type used (suction gripper or two-finger gripper). Gripping points are transmitted to the robot system as complete poses - either in the form of a homogeneous 4×4 transformation matrix or as translation + quaternion. This enables direct integration into the robot controller.

In addition, each gripping point is given the dimensions of the maximum available gripping surface, which is defined as an ellipse. By specifying the minimum dimensions of the gripping surface, points with surfaces that are too small can be filtered out and the largest possible gripping ellipse can be selected.

Intelligent collision avoidance for safe gripping processes

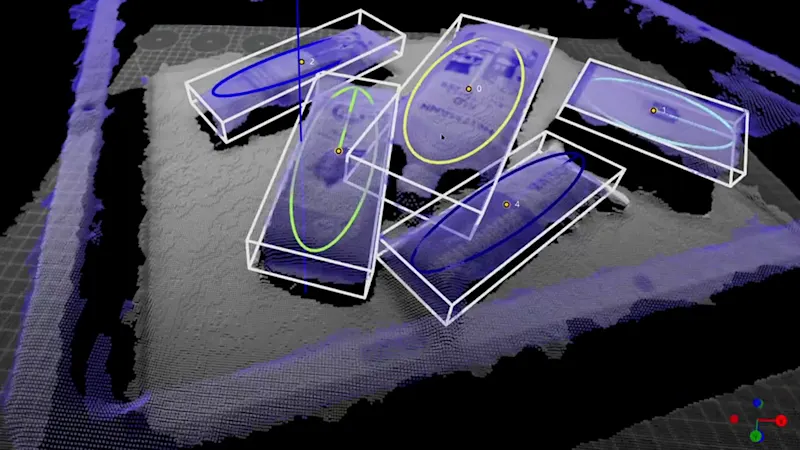

Avoiding collisions is crucial for smooth robot operation in order picking, especially with densely packed containers. ItemPickAI checks potential gripping points for collisions with load carriers and the environment and provides corresponding status messages for the robot controller. This allows the user to activate a check routine, for example, which takes possible collisions with the underside of the load carrier into account. Alternatively, ItemPickAI determines the minimum distance between the gripper geometry and the load carrier to enable collision-free gripping processes.

Based on the 3D point cloud, the software not only evaluates potential collisions between the gripper and the load carrier - it also takes adjacent objects into account in order to identify a safe gripping point. The processing of 3D point cloud data enables the flexible connection of different 3D cameras. Gripping point determination with automatic detection and avoidance of collisions reduces product damage and incorrect grips.

ItemPickAI: Increased efficiency, error reduction, and increased flexibility

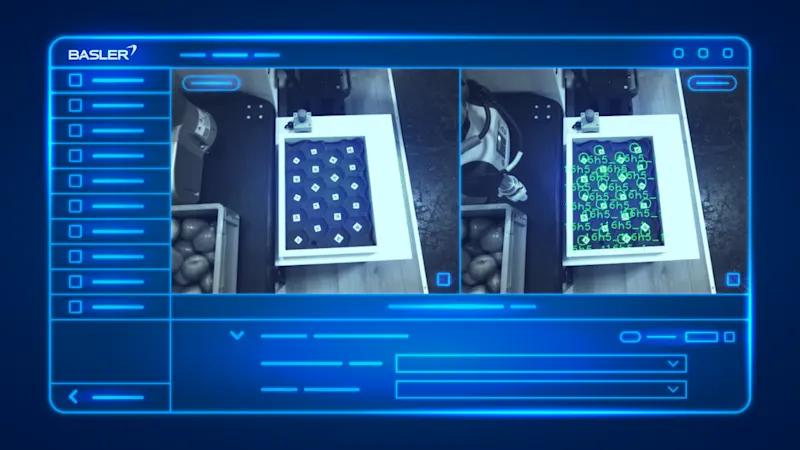

Real-time object recognition: For fast processes thanks to AI analysis directly on the 3D Camera Cube

Precise AI-based gripping point calculation: Powerful neural networks determine gripping points based on 2D and 3D image data.

Precise picking: ItemPickAI reliably recognizes consumer goods even in mixed containers and provides collision-checked gripping points for the robot.

Product protection: The intelligent gripping point detection of ItemPickAI helps protect items and packaging from damage. Even with challenging surfaces such as glossy or partially transparent packaging, stable gripping points can be found.

Adaptability: ItemPickAI provides suitable gripping points and orientations for suction grippers and two-finger grippers according to requirements.

Scalability: ItemPickAI is suitable for different warehouse sizes and a wide range of consumer goods categories.

Robot Integration

We offer various solutions so you can easily use our 3D cameras and software modules with your preferred robots. Integration modulesand sample programs are available for many common robot brands, allowing the vision solution to be integrated into the robot controller.

EKIBridge for KUKA

URcap for Universal Robots

Generic Robot Interface for ABB, FANUC, and Techman Robot. Franka Robotics, Fruitcore Robotics, and Yaskawa will follow soon. We are happy to provide them on request.

Is your robot not listed? We will find a way to support you!

Contact us3D solution for your robot system

ItemPickAI uses the data provided by 3D cameras to reliably capture the scene and perform precise point cloud analysis: Integration takes place via standardized interfaces such as GenICam or GigE Vision as well as the pylon SDK.

The Basler stereo visard or stereo ace cameras enable precise depth detection of the recorded scene. They can either be mounted on arm (directly on the robot) or positioned statically off arm.

Basler 3D Camera Cube is necessary as a powerful embedded PC for image processing and for handling computationally intensive applications such as ItemPickAI. It is always required for the stereo ace camera, and for demanding scenarios with the stereo visard.

Stereo Camera Randomdot Projector It creates a high-resolution, random dot pattern on the scene, providing improved depth detection and more accurate point clouds, even with difficult surfaces and lighting conditions."

Products for this solution

Looking to implement a comparable solution? These products will help you.

Intelligent picking of flexible packaging with AI

The ItemPickAI software uses a neural network to determine precise gripping points for robot-assisted pick-and-place applications with suction pads. Even flexible and previously unknown objects of a defined category are reliably recognized - even with unstructured goods delivered in containers or load carriers. Both unmixed and mixed loads can be processed without any problems.

Different object categories, such as consumer goods or even bags, can be flexibly adapted at any time. This allows picking and (de)palletizing processes to be implemented easily and efficiently - without the need for specialist knowledge in the field of AI or image processing.

ItemPickAI Bag Sorting