SWIR Cameras Without Sensor Cooling

Best image quality thanks to new sensor technology and unique camera features

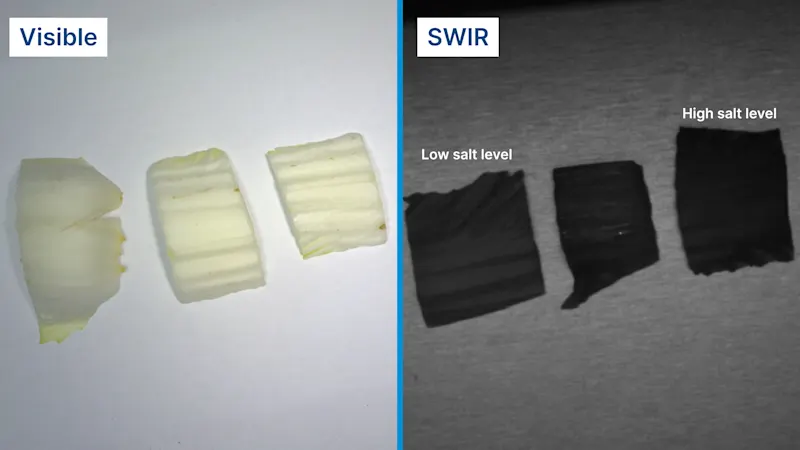

The image quality of conventional InGaAs sensors decreases significantly with increasing exposure time and increasing sensor temperature. For this reason, SWIR sensors are often equipped with integrated thermo-electric cooling (TEC). However, this requires larger and more expensive camera designs. Sony has achieved significant technological improvements in the new SenSWIR sensors. This ensures very good image quality - without any cooling, depending on the exposure time.

Last updated: 09/09/2025

Differences between TEC and TECless SWIR cameras

Apart from the image quality, there are some differences between the two camera types. TECless cameras offer many advantages.

Advantages of SWIR cameras without TEC sensors

The camera housing can feature a smaller design because no internal cooling is required

Significantly lower price

No fans that generate air turbulence, which is particularly advantageous in clean rooms

No vibrations due to fans, which avoids measurement inaccuracies

Lower power consumption, as no thermoelectric cooling modules or fans are required

Operation via just one cable is possible, also with USB

TEC camera | TECless camera | |

|---|---|---|

Housing size | ⬆️ | ⬇️ |

Price | ⬆️ | ⬇️ |

No moving parts | ❌ | ✅ |

Power consumption | ⬆️ | ⬇️ |

How does sensor temperature affect image quality?

Three noise sources essentially influence the signal-to-noise ratio (SNR) and therefore the image quality: read noise, photon noise (photon shot noise), and dark current noise. However, only the dark current is temperature-dependent. As the pixel structure and readout electronics of cooled (TEC) and uncooled (TECless) SenSWIR sensors are identical, the image quality of the two variants at longer exposure times differs only in the dark current noise.

Sensor temperatures and signal-to-noise ratio

The relevance of the individual aspects of image quality depend heavily on the requirements of the application. For some applications it is essential that the noise is minimal, for others it is a matter of the greatest possible dynamic range. And still others need to identify the smallest structures. This is why there is not just one parameter that represents image quality, but several. Because only the influence of temperature and therefore the dark current noise are relevant in this case, the SNR is a suitable indicator to quantify the changes in image quality. As the SNR only considers homogeneous surfaces, structures and the edge profile must also be taken into account.

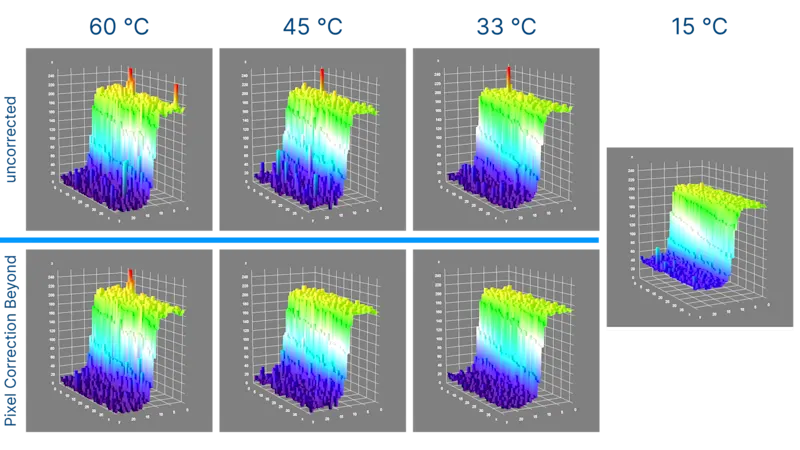

Camera setups with representative sensor temperatures

In order to compare the image quality, we use four different camera setups with typical sensor temperatures at maximum frame rate:

Uncooled, unmounted camera with approx. 60 °C sensor temperature

Passively cooled camera with approx. 45 °C sensor temperature

Camera actively cooled with compressed air cooler with approx. 33 °C sensor temperature

Camera with TEC sensor with approx. 15 °C sensor temperature

Effect of exposure time on the image quality of SenSWIR sensors

How do SenSWIR sensors behave at different exposure times in terms of image quality? Do they need to be cooled?

Exposure times under 10 milliseconds

Extensive series of measurements show that TEC sensors offer no advantage in terms of image quality at exposure times of less than 10 ms. This exposure time corresponds to a frame rate of 100 fps with continuous image acquisition. SenSWIR technology already minimizes the typical problems of conventional InGaAs sensors here.

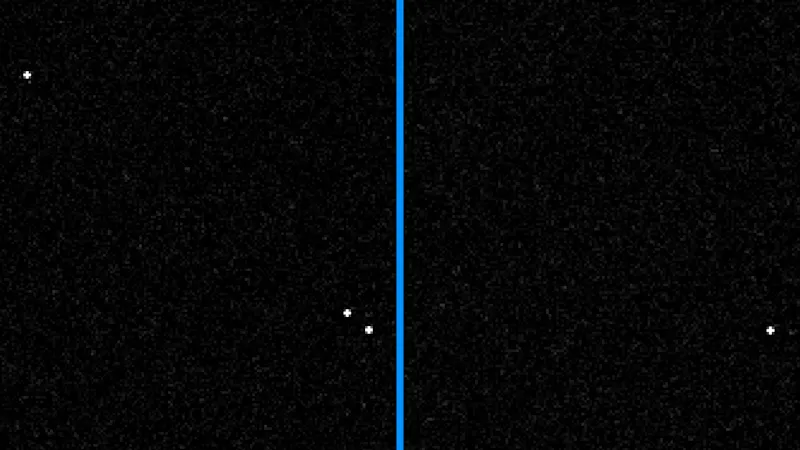

Even when comparing very different sensor temperatures (15 °C vs. 60 °C) with an exposure time of 10 ms, no particular deviation in the image quality of TEC and uncooled SenSWIR sensors can be determined. The SNR shows no significant difference. The same result can be seen in the qualitative view of the structures or the edge profile.

Sensor cooling therefore does not provide a decisive advantage - the influence of the dark current is negligible in this exposure time range. Around 80 % of all SWIR applications use such short exposure times.

Exposure times above 10 milliseconds

With longer exposure times, the sensor temperature plays a greater role. As the sensor temperature rises, the influence of the dark current increases and the SNR decreases, causing the image quality to deteriorate. The main cause is defective pixels, the so-called "hotspots", which can be recognized as white dots in the image. The higher the sensor temperature and the longer the exposure time, the more hotspots occur (Fixed Pattern Noise - FPN). At the same time, the higher dark current also increases the so-called dark current shot noise, which manifests itself as random noise (RN).

A TEC sensor generally improves the image quality for exposure times above 10 ms. However, the disadvantages of a sensor without TEC can be compensated by an external cooling solution and dedicated firmware depending on the respective application setup and the image quality requirements. It is therefore worth checking whether the image quality of an uncooled SenSWIR sensor is sufficient in the application to benefit from its advantages.

The general assumption that cooling is always necessary in SWIR imaging to achieve sufficient image quality is incorrect for SenSWIR sensors.

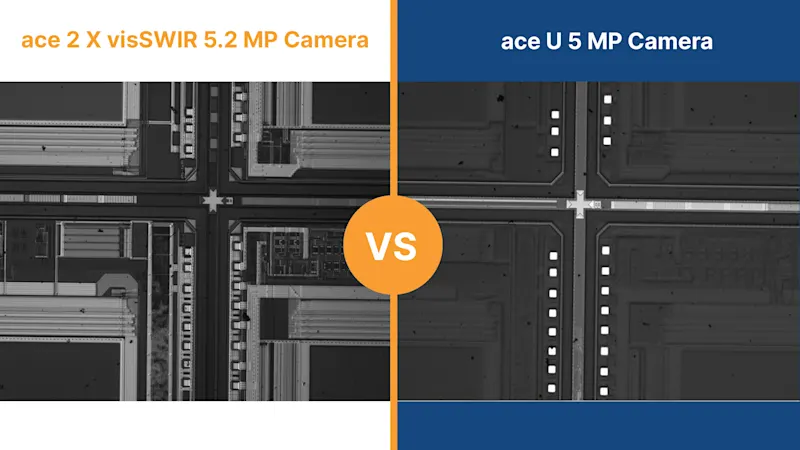

Image optimizations in the camera

The image quality can be improved through post-processing. In addition to the standard static defect pixel correction, our ace 2 X visSWIR cameras offer further patented camera features to optimize image quality. These include extended dynamic defect pixel correction (Pixel Correction Beyond), which eliminates individual defects, as well as noise reduction and sharpening functionalities (PGI Feature Set).

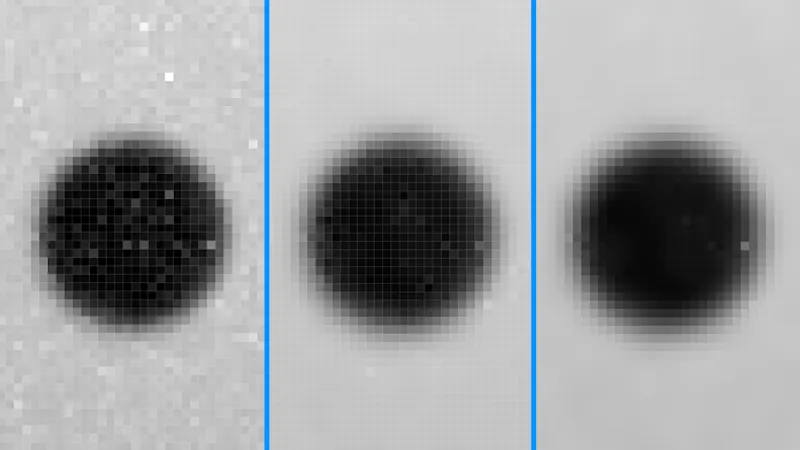

Pixel Correction Beyond for the reduction of pixel errors

Our unique Pixel Correction Beyond algorithm was developed to eliminate the pixel errors commonly found in industrial SWIR imaging. By incorporating the image content and flexibly adjusting the correction strength, significantly better SWIR image results are achieved.

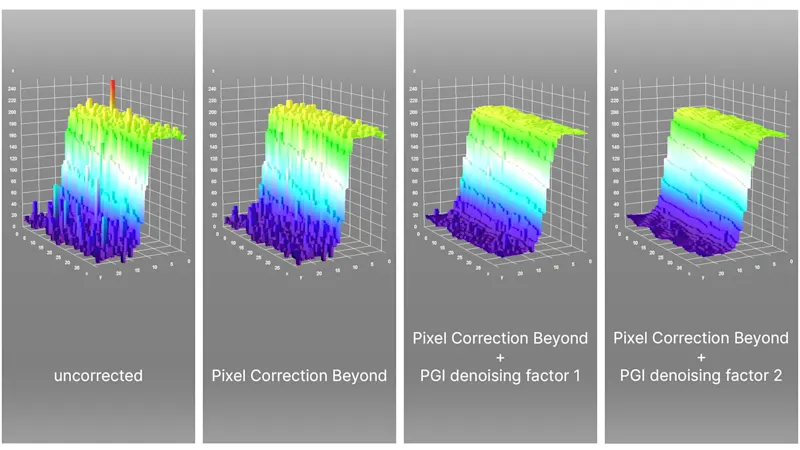

Effects on the fixed pattern noise

Pixel Correction Beyond reduces the fixed pattern noise, which is characterized by defective pixels (hotspots and blinking hotspots), in real time and preserves the smallest structures. The number 5 in the example image has two hotspots close to the edge. These have disappeared after the correction without affecting the structure of the 5.

Effects on the SNR

Pixel Correction Beyond reduces the influence of disruptive defective pixels, such as hotspots, flashing hotspots, or dead pixels in the image. This significantly increases the SNR. A level similar to that of TEC cameras can be achieved.

Effects on the edge profile

At the considered sensor temperatures and an exposure time of 200 ms, Pixel Correction Beyond removes the largest hotspots and improves the edge curve at higher temperatures. Random noise, on the other hand, is reduced by cooling and the resulting lower sensor temperature - the edge curve becomes smoother. When comparing the edge curve at 33 °C sensor temperature using Pixel Correction Beyond with the edge curve at 15 °C, there is hardly any difference - even with a relatively long exposure time of 200 ms.

Reduction of the blooming effect

Under extreme conditions such as a sensor temperature of 60 °C and an exposure time greater than 100 ms, so-called "blooming hotspots" can occur. These are clusters of hotspots that occur when a hotspot radiates onto other pixels. In this case, the "Blooming Reduction", a SenSWIR-specific feature from Sony, can be used. This minimizes the occurrence of blooming hotspots, although this is only successful in around 50 % of all cases. Whether or not blooming hotspots are a problem must be determined for each individual application.

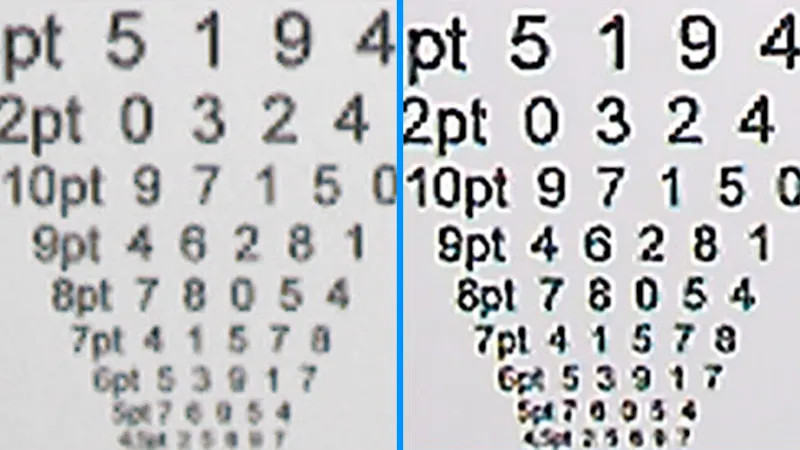

PGI for noise reduction and image sharpness

Our tried-and-tested PGI feature set offers another way to optimize image quality. Denoising reduces random noise without affecting the edges. To compensate for blurring of the image, Sharpening can be used to accentuate the edges and additionally optimize the sharpness of the image. This makes it possible to individually adapt the image quality to the inspection task.

Denoising significantly minimizes noise on areas in the image, which can be infinitely adjusted using various parameters.

Image sharpness optimization for fine and sharp-edged structures, such as letters, numbers, and barcodes

Pixel Correction Beyond and Denoising

What effect does the combination of Pixel Correction Beyond and Denoising have on the edge profile? The noise is reduced while the structures in the image are retained. Unlike with simple noise reduction algorithms, the gradient and amplitude between the high and low intensity (gray) value levels are retained. With stronger noise reduction, it should be noted that blurring in the image can increase. Here it is important to carefully balance the parameters for noise reduction and sharpening.

External, fanless cooling as an alternative to TEC sensors

Even a moderate reduction of the sensor temperature from e.g. 60 °C to 45 °C or 33 °C has a positive effect on the image quality of the SenSWIR sensors. To achieve this temperature stabilization, Basler offers two cooling solutions. These work without a fan, which means that all the advantages of an uncooled camera over a camera with integrated cooling are retained, even with longer exposure times of more than 10 ms.

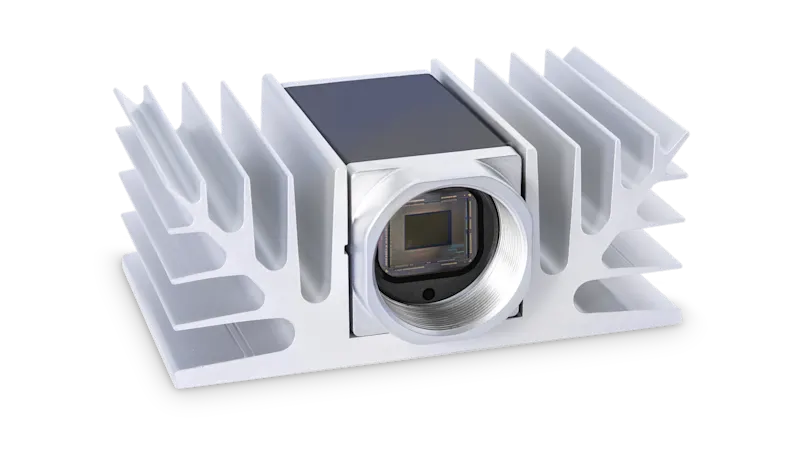

Passive cooling fins

Easy to use, especially suitable for initial evaluation

No moving parts

Stabilizes the sensor temperature to < 45 °C (depending on air circulation and ambient conditions)

Active compressed air cooler

Excellent cooling performance with a small footprint

No moving parts

Stabilizes the sensor temperature to < 33 °C (depending on air circulation and ambient conditions)

TECless cameras offer many advantages

The general assumption that TEC sensors always deliver better image quality in SWIR imaging is incorrect. Rather, it depends on the specific application. For example, TEC-SenSWIR sensors offer no advantage in terms of image quality compared to uncooled SenSWIR sensors at exposure times of less than 10 milliseconds. On the other hand, there are the many disadvantages of cameras with TEC sensors. For longer exposure times, our combined solution of cooling accessories and camera features offers a cost-effective alternative to the high-priced cameras with TEC sensors. Depending on the application, this solution achieves the image quality of cameras with TEC sensors. It is therefore worth taking a closer look to find the optimum solution for your individual application.

TEC camera | TECless camera | |

|---|---|---|

Housing size | ⬆️ | ⬇️ |

Price | ⬆️ | ⬇️ |

No moving parts | ❌ | ✅ |

Power consumption | ⬆️ | ⬇️ |

Image quality of the new senSWIR InGaAs technology under 10 ms | ✅✅ | ✅✅ |

Image quality of the new senSWIR InGaAs technology over 10 ms | ✅ | ✅ |

Our SWIR products

Find special SWIR hardware and software for your vision system here.