Basler ace L and pylon enable AOI of reflective parts

Qu’est-ce que l’AOI des pièces automobiles haute brillance ?

Helmee Imaging produit des systèmes pour l’inspection optique automatisée de pièces à surfaces réfléchissantes. Le client d’Helmee, Sarrel, est l’un des plus grands fabricants de pièces automobiles et est spécialisé dans le placage sur plastiques (PoP). Le système AOI d’Helmee mesure et vérifie la qualité optique des pièces chromées de Sarrel. Il remplace le tamisage et le tri manuels de la ferraille.

Quel est le problème avec l’inspection des pièces automobiles brillantes ?

Cette inspection visuelle nécessite une lumière vive pour trouver des défauts. Cependant, la surface réfléchissante reflète la lumière, ce qui est très fatigant pour les yeux des inspecteurs. L’inspection doit également être rapide. C’est pourquoi Sarrel recherchait des processus de tri automatisés. Étant donné que le système Helmee AOI peut être adapté à presque tous les paramètres, il peut être utilisé pour inspecter optiquement des pièces réfléchissantes de n’importe quelle forme.

La solution pour la détection des défauts sur les pièces automobiles à haute brillance

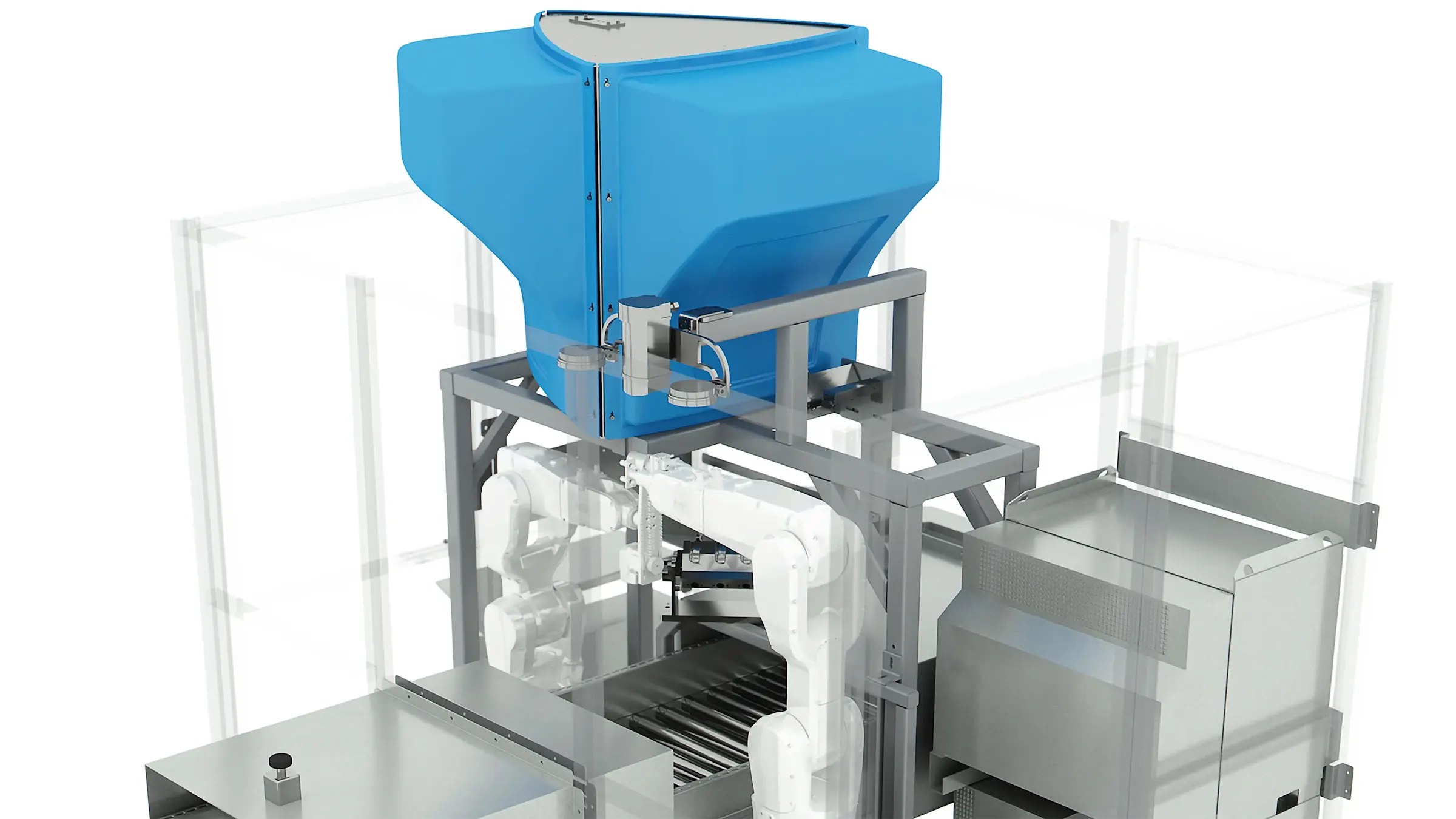

Le système AOI d’Helmee se compose de trois caméras Basler ace, d’un PC industriel, de deux robots industriels, d’un tapis de transport de conteneurs et de barrières de sécurité. Le système retire automatiquement les pièces du client des conteneurs, effectue une inspection 100 % visuelle et trie les pièces en fonction des résultats de l’inspection.

Helmee a récemment converti son système AOI de la caméra Basler ace Classic à la caméra Basler ace L. La raison en était que l’ace L offre un cercle d’image plus grand de 1 pouce, ce qui signifie que Helmee peut utiliser ses propres objectifs de caméra. L’entreprise utilise la suite logicielle Basler pylon Camera pour communiquer avec les trois caméras ace L.

En plus du logiciel d’inspection Helmee AOI, l’entreprise a développé l’AOI Helmee basé sur la technologie brevetée CSD® (Covered Stereo Deflectometry). CSD® est un système de traitement d’images 3D qui détecte automatiquement toutes sortes de défauts dans le chromage haute brillance.

Les avantages d’un système de vision pour détecter les défauts dans les pièces automobiles brillantes

La caméra ace L de Basler offre un grand cercle d’image de 1 pouce et est à la fois flexible et fiable

Les pièces sont manipulées automatiquement

L’inspection peut être intégrée dans le processus de production

Produits pour cette solution

Vous cherchez à mettre en œuvre une solution comparable ? Ces produits vous aideront.