Qu’est-ce que la vision industrielle ?

Le traitement d’images industrielles, souvent appelé vision industrielle, est devenu un élément indispensable de l’automatisation et de l’assurance qualité. Grâce à l’utilisation de systèmes de caméras de pointe, les processus peuvent être optimisés, la qualité augmentée et les coûts de production réduits à long terme.

Précision et efficacité grâce à la technologie de vision industrielle

La vision industrielle est un domaine de l’automatisation industrielle qui traite de l’acquisition et de l’analyse d’images pour contrôler, réguler et surveiller les processus automatisés. Cette technologie utilise des caméras numériques, des logiciels de traitement d’images et des systèmes optiques pour capturer des images d’objets et analyser leurs caractéristiques.

Fonctionnement des systèmes de vision

Un système de vision industrielle est généralement constitué de plusieurs composants qui fonctionnent ensemble. Par exemple, une caméra de vision industrielle capture une image d’un produit sur un tapis roulant. Ces images sont ensuite traitées à l’aide d’un logiciel de traitement d’images spécialisé, tel que la suite logicielle Basler pylon. Dans ce logiciel, des algorithmes sont utilisés pour détecter et vérifier certaines propriétés telles que la taille, la forme, la couleur ou l’état de surface.

Les résultats de ces tests peuvent ensuite être utilisés pour effectuer des contrôles qualité, contrôler les étapes de fabrication, trier des pièces ou automatiser des tâches de mesure.

Les avantages du traitement d’images industriel dans l’automatisation et l’assurance qualité

Le traitement d’image industriel est aujourd’hui indispensable dans la production. Grâce à la détection optique et à des analyses puissantes, la vision industrielle améliore la qualité, la précision et l’efficacité des processus de production. Avec une vitesse élevée et une précision constante, cette technologie surpasse les capacités des inspecteurs humains.

Augmentation de la vitesse de production

Les systèmes de vision industrielle permettent des inspections en temps réel et une collecte rapide des données, augmentant ainsi le débit, sans sacrifier la qualité.

Flexibilité dans différentes applications

Les systèmes de vision sont polyvalents et peuvent effectuer des tâches telles que le positionnement de composants, l’inspection de surface ou les mesures.

Augmenter la qualité

Les caméras haute résolution détectent même les plus petits défauts, réduisant ainsi les rebuts et les retouches.

Réduction des coûts de main-d’œuvre

Grâce à l’automatisation, la vision industrielle remplace les inspecteurs humains et réduit les coûts tout en maintenant ou en augmentant l’utilisation de la production.

Amélioration de la sécurité au travail

Dans les environnements dangereux, les systèmes de caméras prennent en charge les inspections à haut risque, minimisent les dangers et protègent les employés.

Maintenance préventive

La vision industrielle permet une maintenance préventive, évite les pannes et prolonge la durée de vie des machines.

Tâches de la vision industrielle

La détection et la localisation d’objets sont des tâches qui peuvent être effectuées de manière excellente à l’aide d’un traitement d’image industriel. Dans cette vidéo, notre expert Thies Moeller explique à l’aide d’exemples concrets comment ces tâches sont abordées par les systèmes de vision industrielle et quel rôle joue le prétraitement d’image à cet égard.

Applications industrielles

Le traitement d’images industrielles est devenu indispensable en tant que technologie clé dans une grande variété d’applications industrielles. Grâce à l’utilisation de caméras sophistiquées et d’un logiciel de traitement d’image intelligent, elle permet une précision et une efficacité inégalées dans les processus de production.

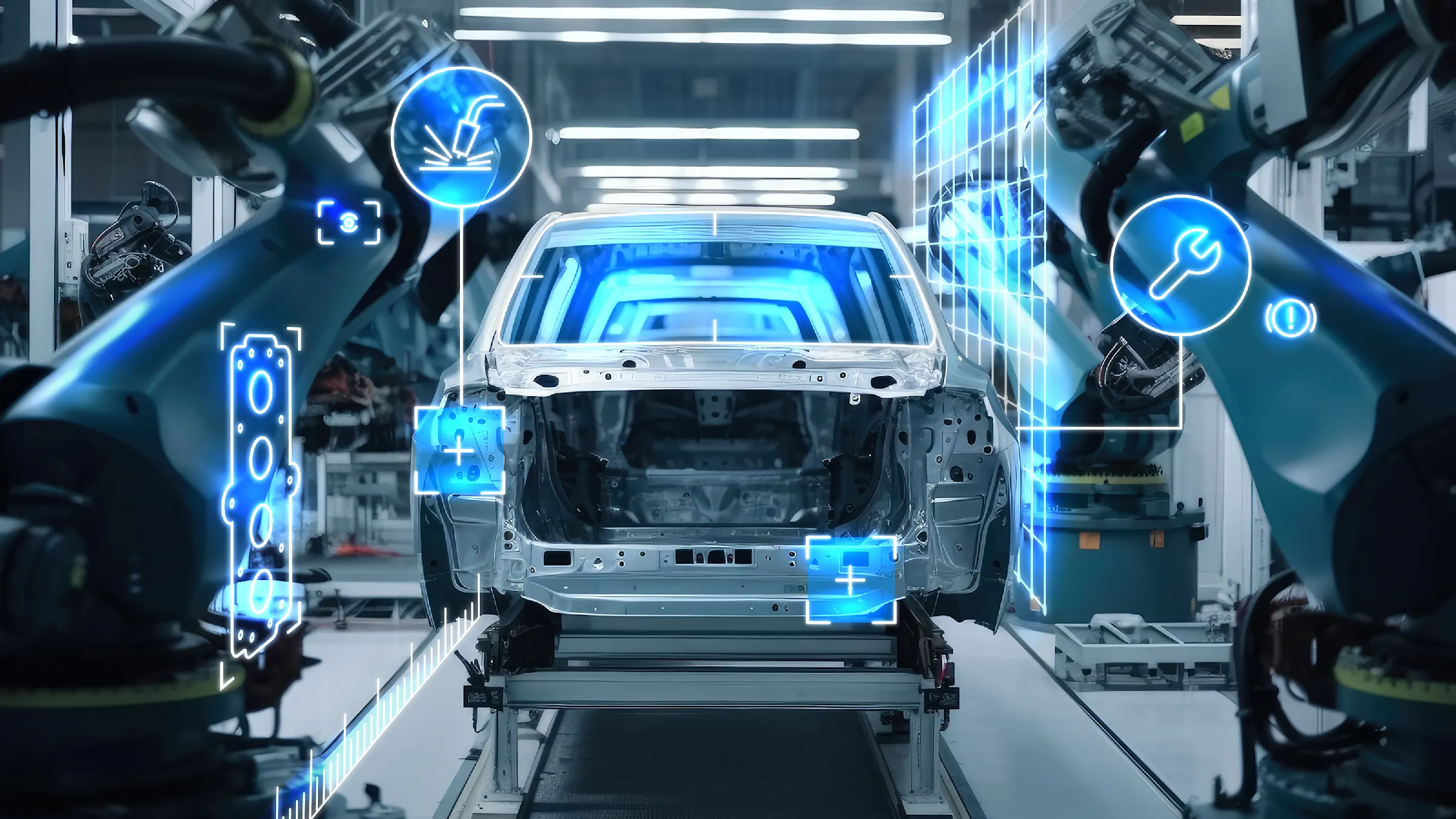

Robotique et automatisation

La robotique guidée par l’image utilise des caméras pour guider et contrôler les robots. Dans les tâches de pick-and-place, les caméras identifient les objets, déterminent leur position et leur orientation afin que les bras robotiques puissent les saisir et les placer correctement. Cette application se retrouve souvent dans l’industrie automobile et dans la technologie de l’emballage.

Trafic & ; Transport

Dans l’ingénierie du trafic , la vision industrielle joue un rôle important dans la reconnaissance des plaques d’immatriculation, la surveillance de la vitesse ou l’inspection des rails.

Production de cellules de batterie

Dans la fabrication de cellules de batterie , le traitement d’image industriel permet de réduire les rebuts et les retouches, ce qui permet de réduire les coûts et d’augmenter l’efficacité de la production. De plus, l’utilisation de la vision industrielle peut améliorer le rendement, car les inspections automatisées sont effectuées en temps réel et n’interrompent pas le flux de production.

Industrie de l’imprimerie

Dans l’industrie de l’imprimerie , la vision industrielle est utilisée pour surveiller le processus d’impression, détecter les écarts de couleur ou les défauts d’impression. Les caméras à haute vitesse peuvent surveiller le processus d’impression en temps réel et intervenir immédiatement en cas d’écart.

Industrie alimentaire

L’inspection optique des aliments à la recherche de corps étrangers, d’une taille correcte, d’une maturité ou d’une infestation de moisissures est également un domaine d’application des systèmes de vision industrielle. Par exemple, les fruits peuvent être triés automatiquement ou l’emballage peut être vérifié pour s’assurer qu’il est complet et que l’étiquetage est correct.

Industrie pharmaceutique

Dans l’industrie pharmaceutique , une qualité de produit extrêmement élevée est requise pour assurer la santé des patients. Les systèmes de vision industrielle inspectent les tablettes et les capsules pour vérifier la forme, la couleur et l’intégrité du marquage. La quantité correcte de liquide dans les ampoules ou les flacons peut également être assurée.

Agriculture

Modern agricultural machinery uses machine vision to distinguish plants from weeds and perform targeted fertilization or herbicide treatments. The evaluation of harvested material for maturity and quality or monitoring farm animals is also made possible by industrial image processing.

Vision industrielle pour une qualité de production élevée

La vision industrielle permet d’automatiser les processus, d’améliorer la qualité des produits et d’augmenter l’efficacité. De cette façon, il augmente la qualité des processus de production, réduit les coûts et contribue ainsi à une plus grande compétitivité.

Nos produits pour le traitement d’images industrielles

Utilisez notre configurateur de système de vision et assemblez facilement votre système de vision complet.