La technologie du temps de vol rencontre le robot d’étiquetage

Les processus d’expédition des prestataires de services logistiques mondiaux se caractérisent par un débit de marchandises particulièrement élevé. Dans le même temps, le marché exige une flexibilité toujours plus grande en matière de logistique, ce qui nécessite à son tour des solutions d’étiquetage performantes. Les étiquettes d’expédition sont un élément important de ces solutions : elles rendent les processus logistiques possibles en premier lieu et contiennent des informations telles que l’adresse du client', le logo de l’entreprise, l’expéditeur, les codes-barres et le numéro d’envoi.

Pour répondre à ces exigences, la Bâle a développé, en collaboration avec Vanomation Inc., l’un des principaux fournisseurs d’étiqueteuses industrielles, un système d’impression et d’application d’étiquettes d’expédition dans les entrepôts et les centres de distribution qui manipulent quotidiennement de grandes quantités de colis.

Voici comment fonctionne la solution robotique avec la technologie Time-of-Flight

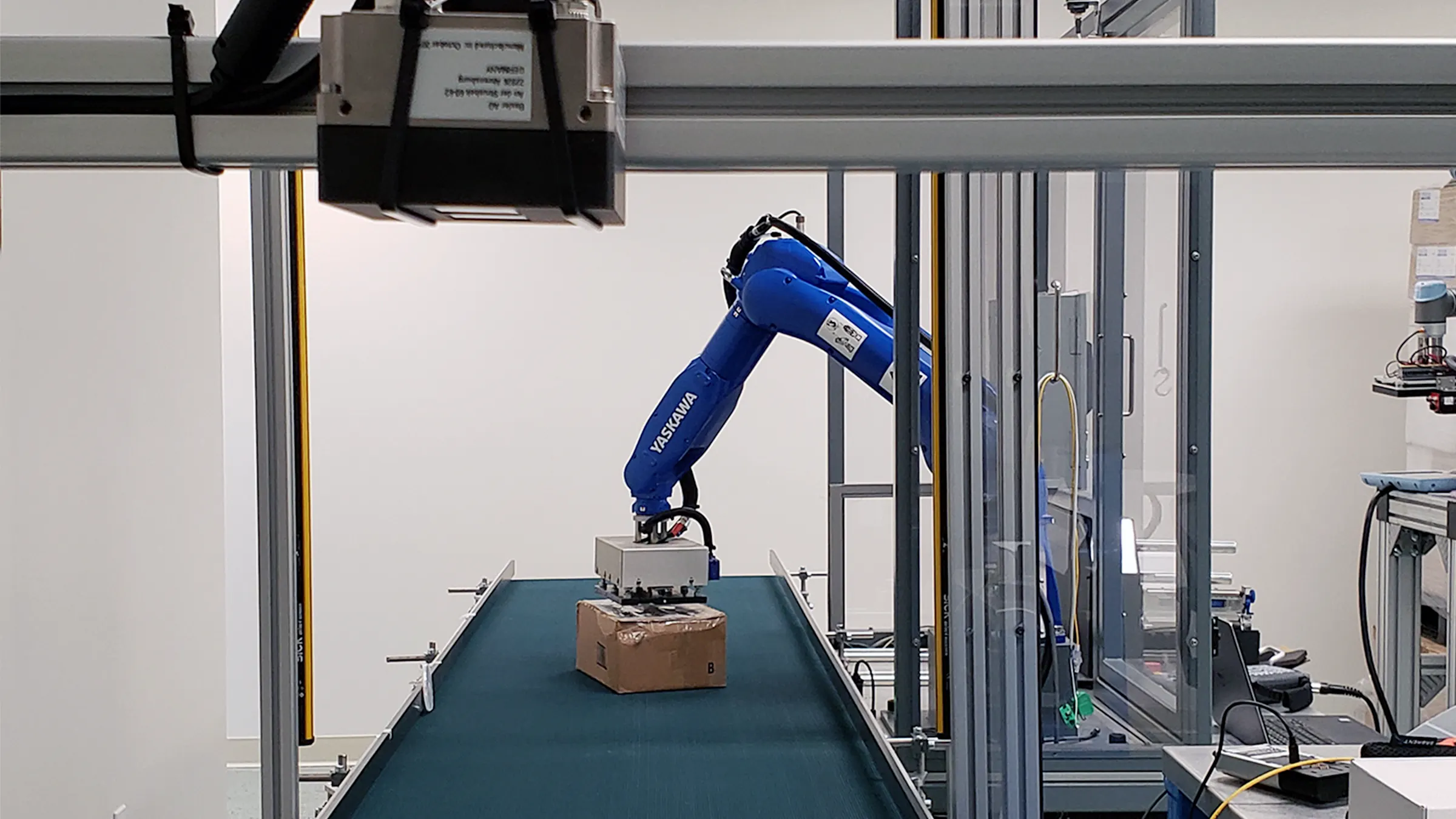

Vanomation a intégré la caméra Basler Blaze Time-of-Flight et le logiciel Blaze spécifique à l’application dans une solution robotique qui permet au système de détecter l’emplacement, l’orientation et la taille d’un colis se déplaçant sur un tapis roulant à grande vitesse et de transmettre ces données au RPA (applicateur d’impression robotisé). Grâce à ces données, le robot peut récupérer l’étiquette adhésive de l’imprimante et la placer dans l’orientation et la position correctes sur l’emballage. Ce système puissant permet de placer avec précision une étiquette n’importe où sur une palette statique ou un colis en mouvement.

Plus rapide et plus flexible avec 3D Vision

Il s’agit d’une solution puissante pour les prestataires de services logistiques. La solution élimine les emballages mal étiquetés et la nécessité de disposer de l’espace de convoyage et de l’équipement supplémentaire nécessaires pour redresser les emballages avant qu’ils ne soient centrés sous les applicateurs d’impression mécanique actuels. L’utilisation de la vision 3D rend la chaîne logistique plus rapide, plus flexible et moins sujette aux erreurs.

Les avantages de cette solution de vision 3D avec la caméra Basler ToF en un coup d’œil

Mesure optique précise et rapide des axes xyz et de l’orientation des objets grâce à la dernière technologie de capteur IMX556PLR DepthSense™ de Sony (temps de vol pulsé)

Intégration facile de la caméra dans le système grâce à une conception compacte sans pièces mobiles et Gigabit Ethernet

Mesures indépendantes de la lumière et du contraste

Diffusion en temps réel de nuages de points 3D prétraités et d’images d’intensité 2D

Support de Basler dans le développement d’un logiciel pour la détection et la mesure d’objets