Efficient Warehouse Management with Rapid Pallet Trackers

Artemis Vision relies on the ace camera for barcode capture

- Client

- Artemis Vision

- Localisation

- Denver, USA

Numérisation automatisée robuste

Dans la gestion d’entrepôt, une rotation élevée des stocks dépend de mouvements de marchandises rapides et sans problème ainsi que de chaînes d’approvisionnement qui peuvent être tracées. C’est là que la numérisation manuelle atteint ses limites, car elle prend trop de temps, est lente et sujette aux erreurs, ce qui entraîne des coûts trop élevés.

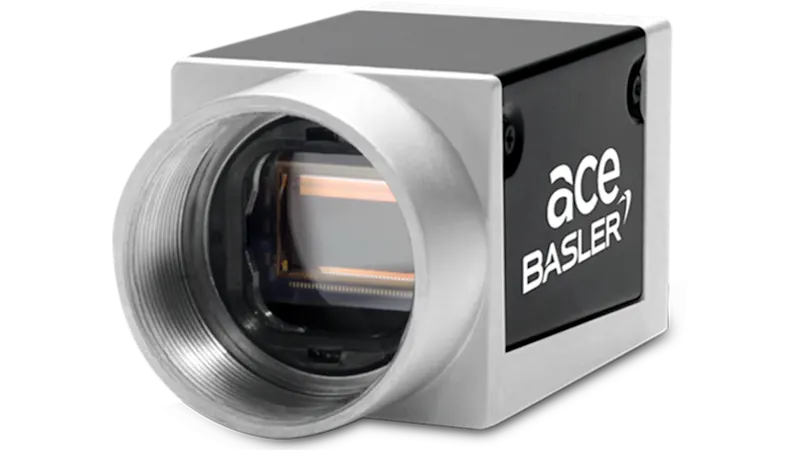

Les marchandises sont souvent déplacées à grande vitesse, en continu et de manière saccadée, ce qui rend difficile la capture fiable des informations d’une étiquette de code-barres. Cela nécessite une technologie rapide et robuste qui offre des performances de reconnaissance élevées. La lecture de codes-barres via le traitement d’image à l’aide de la Basler ace camera est une alternative plus efficace et beaucoup plus rentable au suivi RFID.

Solution déployée

À partir de chaque balayage automatique en temps réel avec le Caméra Basler ace acA2440-35um dans le Rapid Pallet Tracker, une image avec le scan du code-barres est créée. Il est horodaté et stocké dans une base de données qui peut être consultée via un tableau de bord Web. Un tel système de lecture de codes-barres au volant fonctionne sans que les opérateurs de chariots élévateurs aient besoin de s’arrêter ou de descendre et fournit un retour immédiat sur la précision de la lecture.

Nous avons choisi ce modèle de caméra Basler acA2440-35um en raison de son interface USB 3.0 et de son capteur IMX264. Les caméras Basler se distinguent par leur prix compétitif et leurs délais de livraison rapides. En raison de leurs performances, nous avons eu une bonne expérience avec ces caméras dans plusieurs systèmes au fil des ans.

Gain de temps de chargement et autres avantages

Le système permet d’économiser 25 minutes de temps de chargement par camion, ce qui permet à Artemis Vision'Les clients traitent plus de camions par jour. En plus du temps, ils économisent de l’argent grâce à la réduction des coûts de main-d’œuvre et à l’évitement des pénalités des clients et des inexactitudes d’inventaire. Par rapport au coût des étiquettes RFID, le système peut économiser, au minimum, le coût d’un salaire à temps plein par an. Les autres avantages de RaPTr comprennent :

Nécessite très peu d’entretien ou d’espace pour l’équipement

Peut être facilement intégré dans les systèmes ERP existants, mais peut également être utilisé de manière indépendante

Disponible en modèle à une ou deux caméras, en fonction de la taille et du type de codes-barres du client et en fonction de la configuration de l’entrepôt

Produits pour cette solution

Vous cherchez à mettre en œuvre une solution comparable ? Ces produits vous aideront.